Twin Cam Upgrade

Feuling has had its high flow oil pump out for a couple of years now, and we were able to get our hands on this second-generation unit. Same great flow with fewer parts.

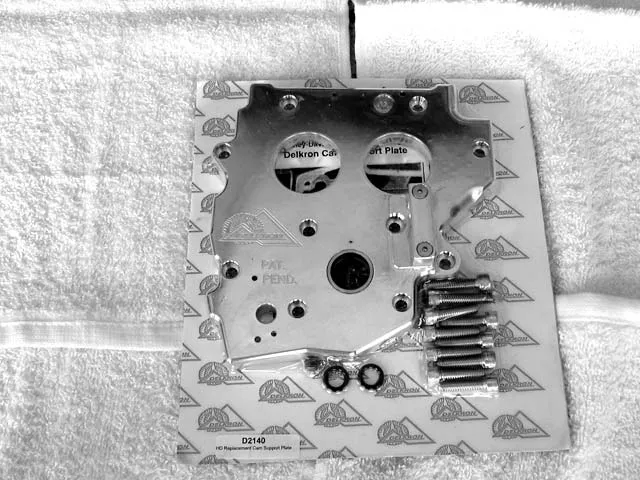

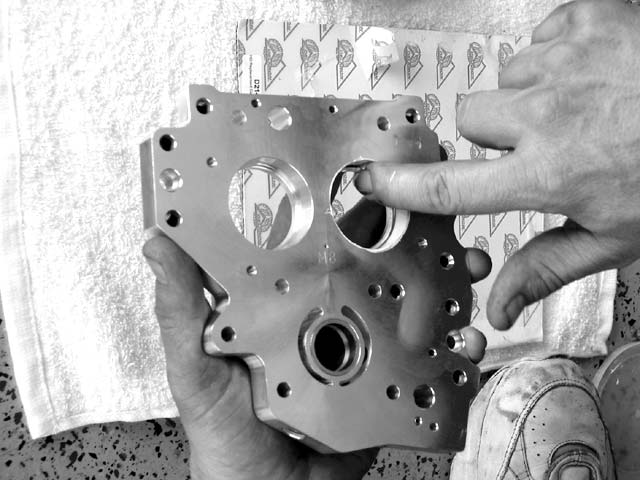

The Delkron cam support plate is a favorite with high-performance engine builders. It offers more strength and support for high lift cams.

With the battery disconnected and the pipe off, we started removing the cam cover.

After the cam sprockets and chain are removed, the support plate can be pulled out.

Look what we found — a broken pump gear!

Pretty scary, huh? This is what we found as the pump came apart.

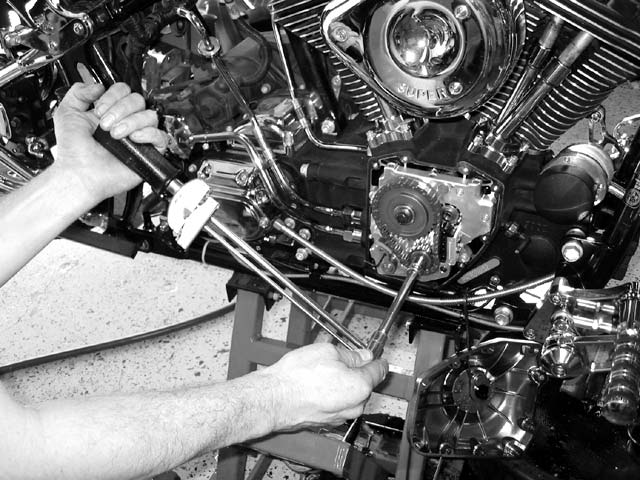

Using a battery terminal puller (improvisation is king), the oil pump gear is pulled off.

With the oil tank out, we started the flushing process by filling the tank with diesel fuel.

With just one good swirling of the diesel, we saw a considerable number of fragments and chips in the pan.

Satisfied the tank was thoroughly cleaned out, a rare earth magnet pilfered from a crashed PC hard drive was attached to the tank, just forward of the feed line, to help catch any future debris.

To help flush the oil lines, we sprayed a liberal amount of Bel-Ray solvent through and caught the residue in a shop rag — more metal was found.

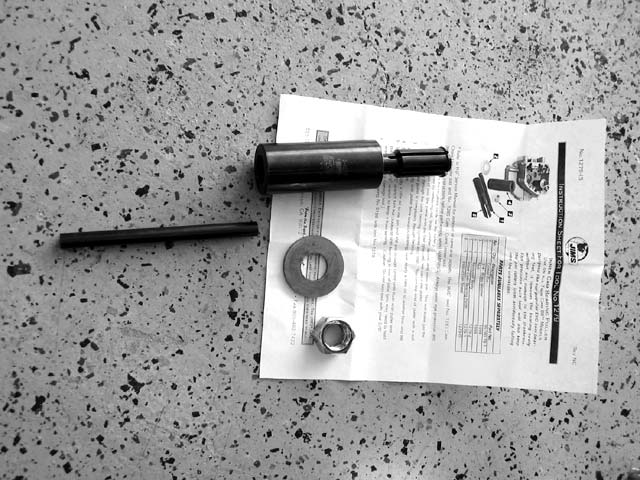

Now it was time to get serious. Rather than take any chances, we planned to replace the inner cam bearings, so we broke out the JIMS cam bearing removal tool.

The puller is simple to use: Slide it in place and twist some wrenches.

We used a JIMS cam bearing installation tool to put the new Torrington bearing in place. Step one, we loaded the bearing on the driver…

…and positioned the plate over the cam cavity, using the supplied set screws to lock it in place. We then simply turned the shaft until it bottomed and the bearing was in place.

Now the cams could be slid out of the old plate. On ’00 models, this is a simple push-out operation; ’01 and ’02s will require a press.

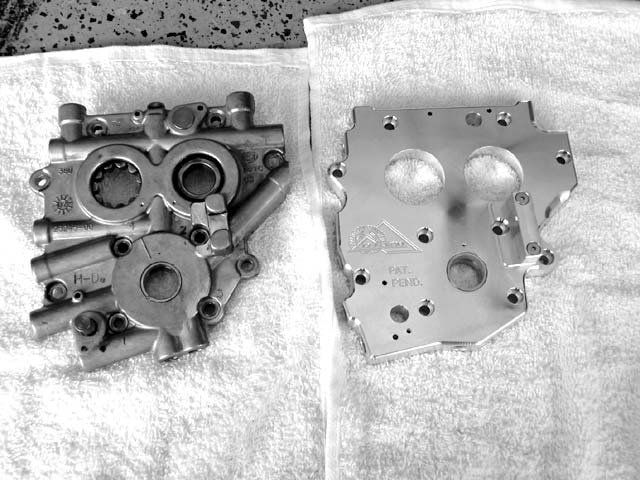

A comparison look at the old cam plate versus the new billet Delkron unit.

A small amount of pre-assembly lube was applied to the plate…

…and a new bearing was pressed in using a socket and a mill.

We used the same press method to remove the cam chain tensioner posts and transfer them to the Delkron plate so the springs could be reinstalled.

More pressing — in this case we really could have used a JIMS cam installation tool — as we set the cams into the new plate.

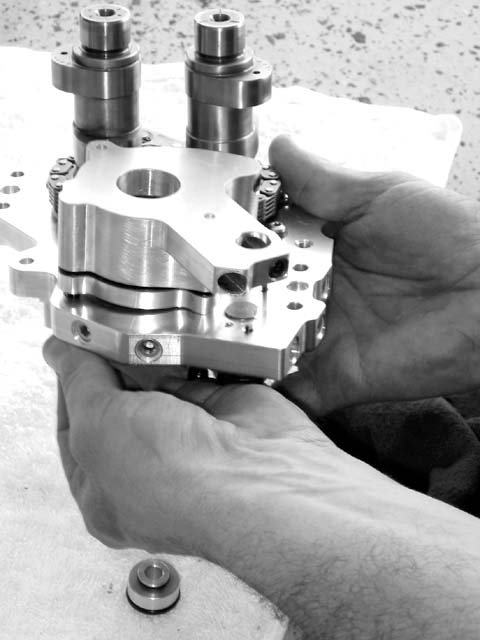

The new Feuling SuperPump oil pump helps eliminate wet sumping and increases oil flow pressures.

After thoroughly cleaning all the parts, the assembly process began. Be very careful with the O-ring gaskets as you install them to assure they do not tear.

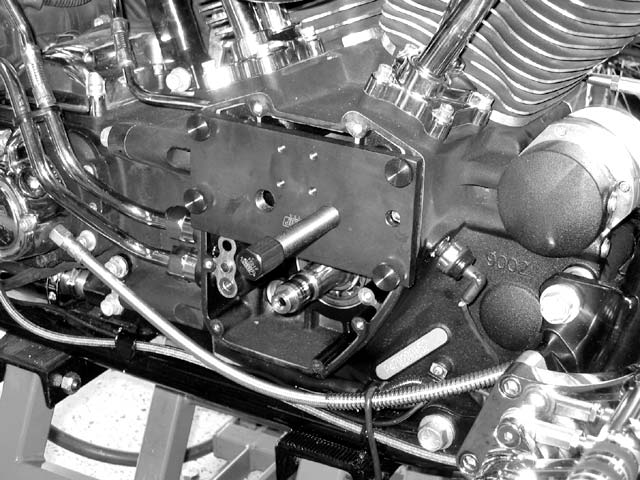

The pump body was fastened to the Delkron plate with thread lock on the bolts…

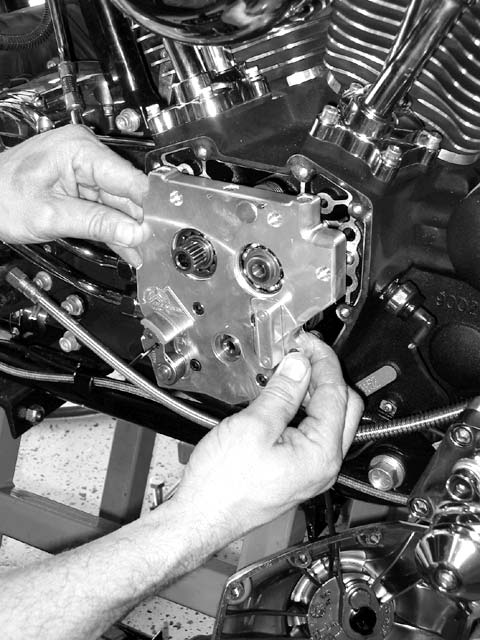

…and the assembly slid back into place.

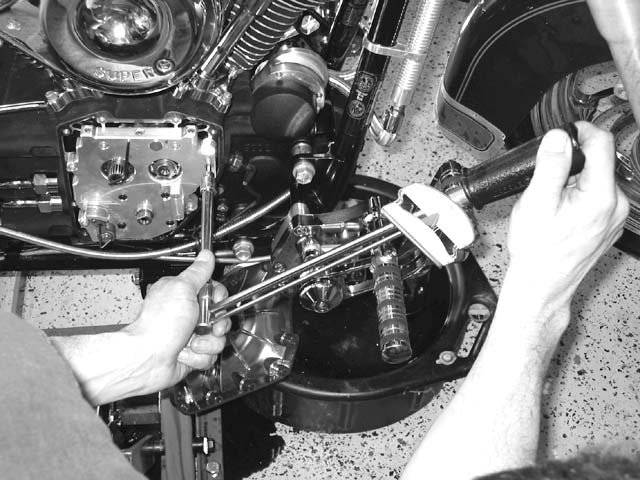

Following the Delkron instructions, the plate was torqued.

The cam gears and chain were installed and the cam cover put back in place.

We installed new lifters from Feuling, just to be safe…

…adjusted the pushrods…

…changed the oil filter, and topped off the oil tank with a fresh fill of Bel-Ray semi synthetic oil. A push of the starter button and things were better than new.

At somewhere around 33,000 miles, Fred Reed’s ’00 Heritage suffered an inner cam bearing failure. He loaded it in a pickup truck and dropped it off at a local dealership, and Harley-Davidson took care of the repairs. However, the dealership cut a few corners, saved a few minutes, and somehow neglected to flush out the oil system — namely the oil tank.

Things went fine until the 43,000-mile point, when the bike was jacked up pretty high in the rear to install some new shocks. The extreme angle let a residual bearing piece roll into the oil feed line, carrying it into the oil pump (one of the original Feuling units) and shattering one of the gears — a failure that could have been avoided with a little extra effort during the rebuild.

Knowing the oil pump was going to have to come out, we took the opportunity to upgrade it to one of Feuling’s new one-piece designs, along with a Delkron cam plate for added beef in the cam support area. Choosing the Delkron cam plate turned out to be a great idea, since the stocker was badly gouged by the broken gear. We did the repair at home using some JIMS cam tools to make things easier.