Twin Cam Engine Build Part 3

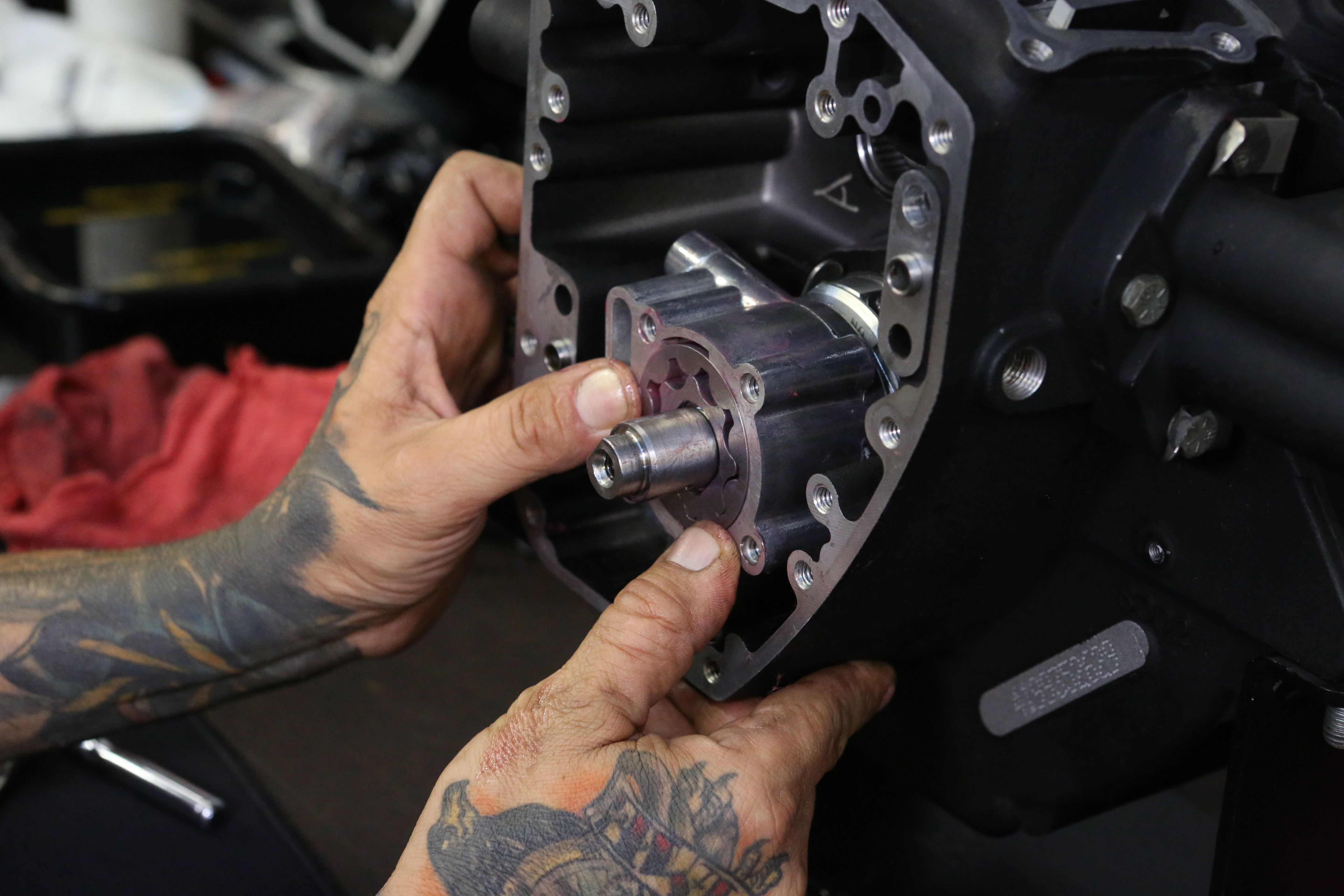

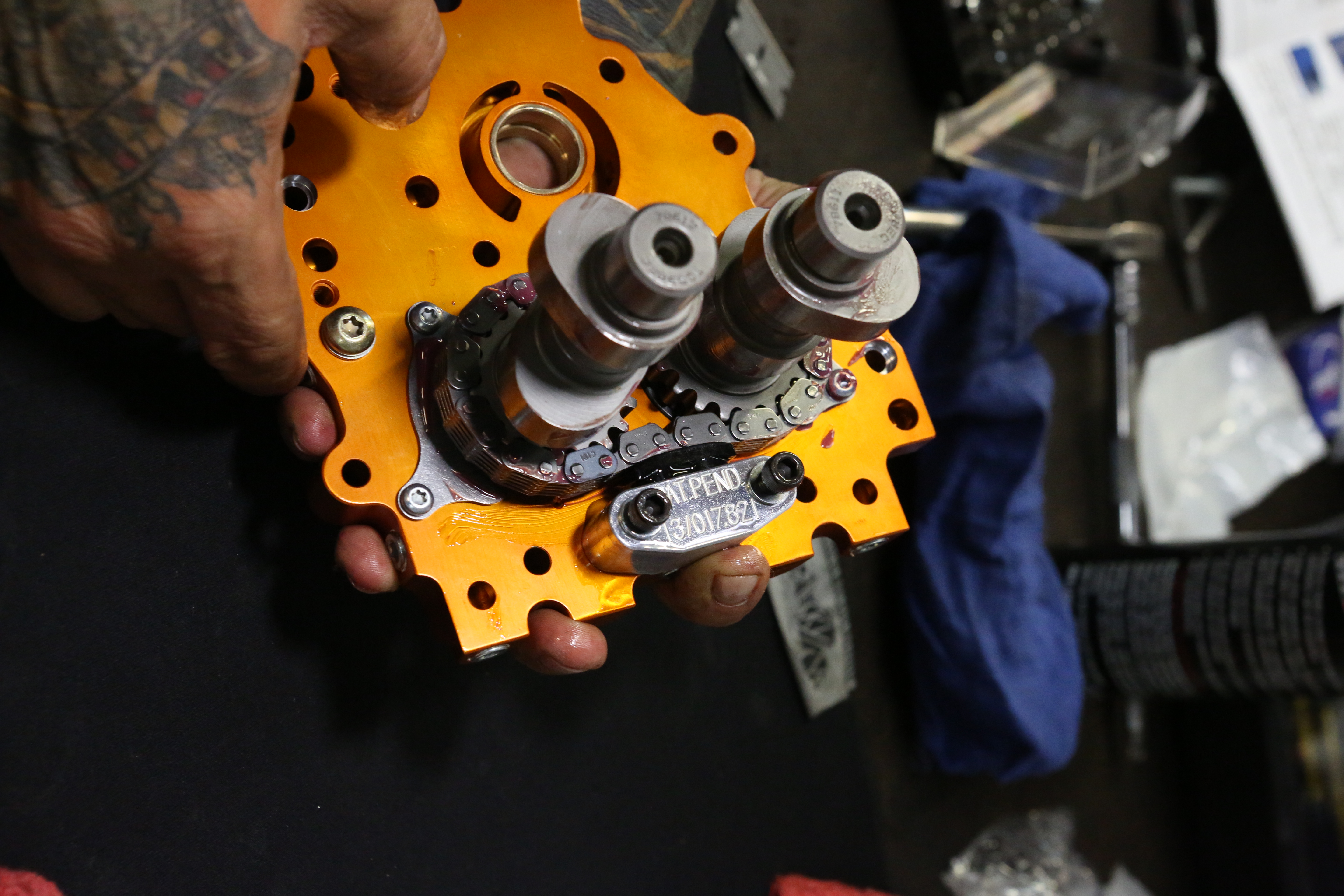

Clean and inspect all parts of the new oil pump. Apply a layer of assembly lube on all moving parts of the pump, and reassemble as per the instructions.

Photo: Hot Bike Staff

Now our Twin Cam “A” rebuild moves to the oil pump and camplate. As you may know from parts 1 and 2 of this story, we pulled the tired Twin Cam mill out of a `99 Harley-Davidson FXDX at the 100,000 mile mark to rehab the poor thing back to full strength.

We broke it down, inspected it, and then sent the lower end to Darkhorse Crankworks (DHC) so its squad of bottom-end experts could rework the tired components. Working with Dave Mackie Engineering (DME), we concocted a solid 107ci top end using bored H-D cylinders and some DME Mega-Sphere pistons, complemented by a DME cam. Both DME and DHC are known for their superior quality and attention to detail, so it was a pleasure to assemble this motor knowing the end result would be a powerful yet balanced blueprinted motor.

Place the oil pump onto the pinion shaft and into its installation position. Be sure to replace the O-ring in the case.

Photo: Hot Bike Staff

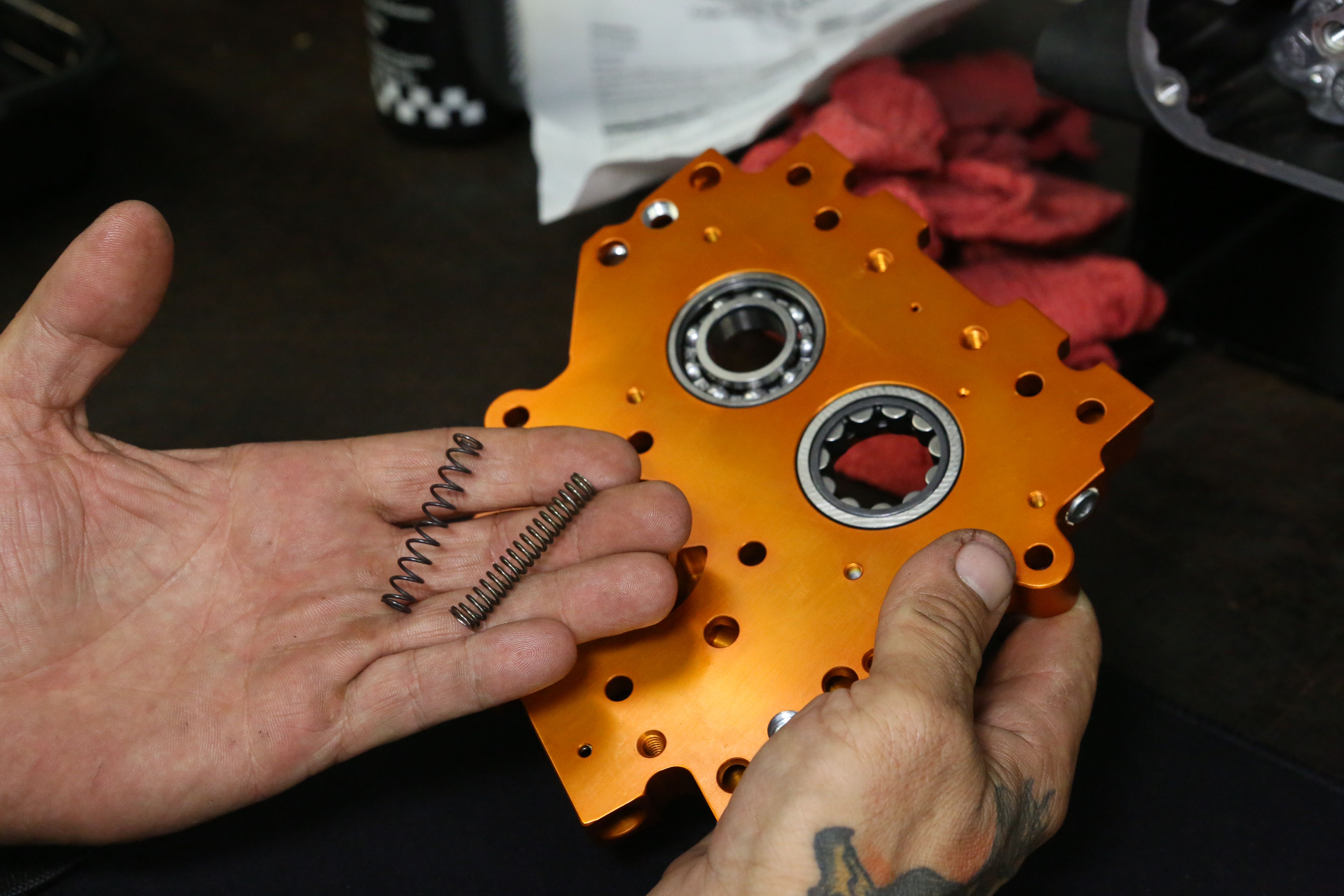

Next, we will replace the oil relief spring in the SE cam plate. We will be using a more aggressively wound, tighter spring from Baisley. Updating this spring provides outstanding oil pressure at all rpms, a much-needed upgrade for any H-D Twin Cam model.

Photo: Hot Bike Staff

Using a punch, remove the roll pin that secures the OEM relief spring from the camplate.

Photo: Hot Bike Staff

RELATED | MORE TECH

Pictured here is the H-D SE oil valve relief spring as compared to the Baisley +15 spring that we are installing. You can see the noticeable difference in the way the coils are wound.

Photo: Hot Bike Staff

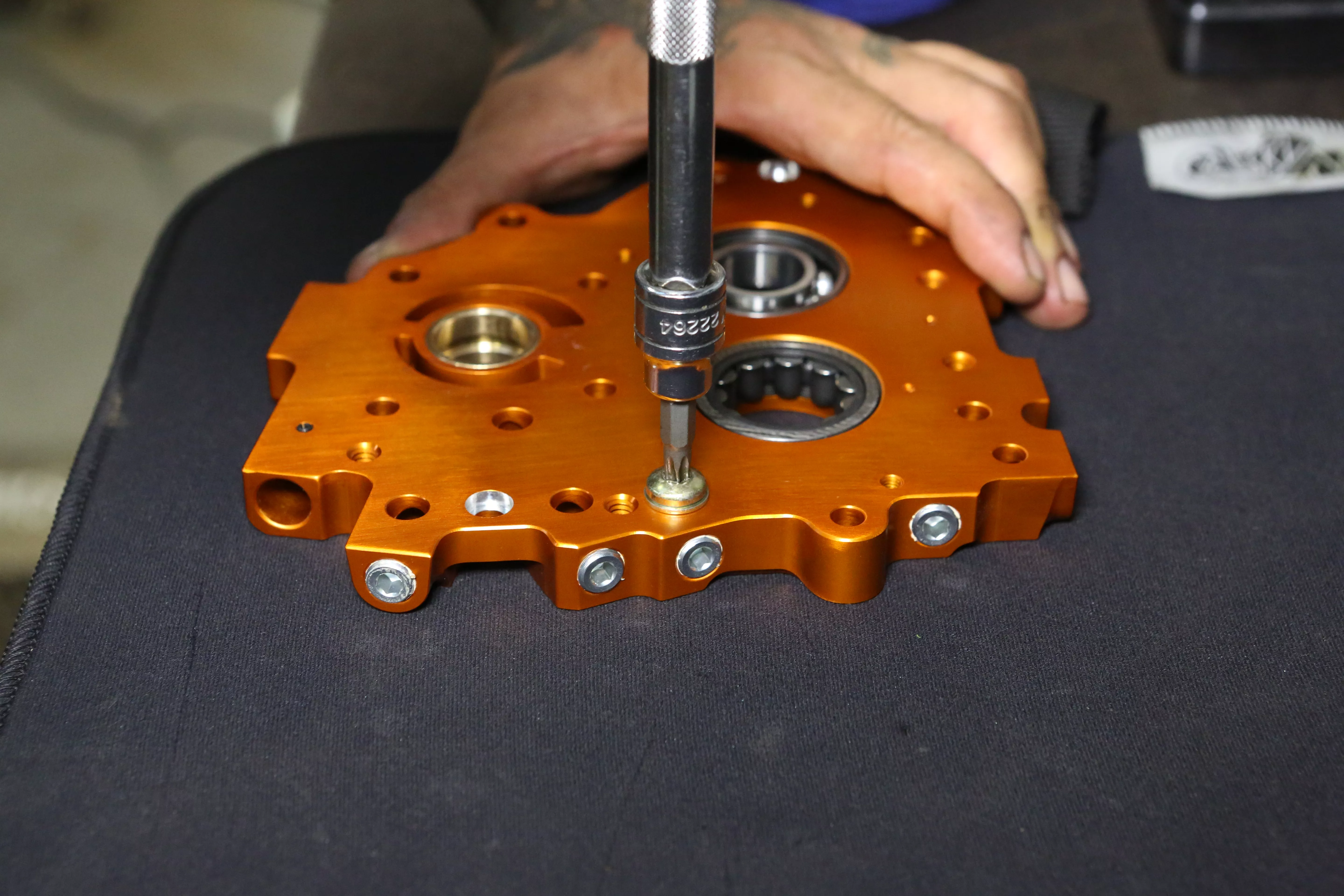

Since we are putting this motor into a 1999 Twin Cam case, we have to block off an oil passage in the new updated camplate. H-D makes an oil passage blocking kit that consists of a sealing washer as well as a Phillips sealing screw.

Photo: Hot Bike Staff

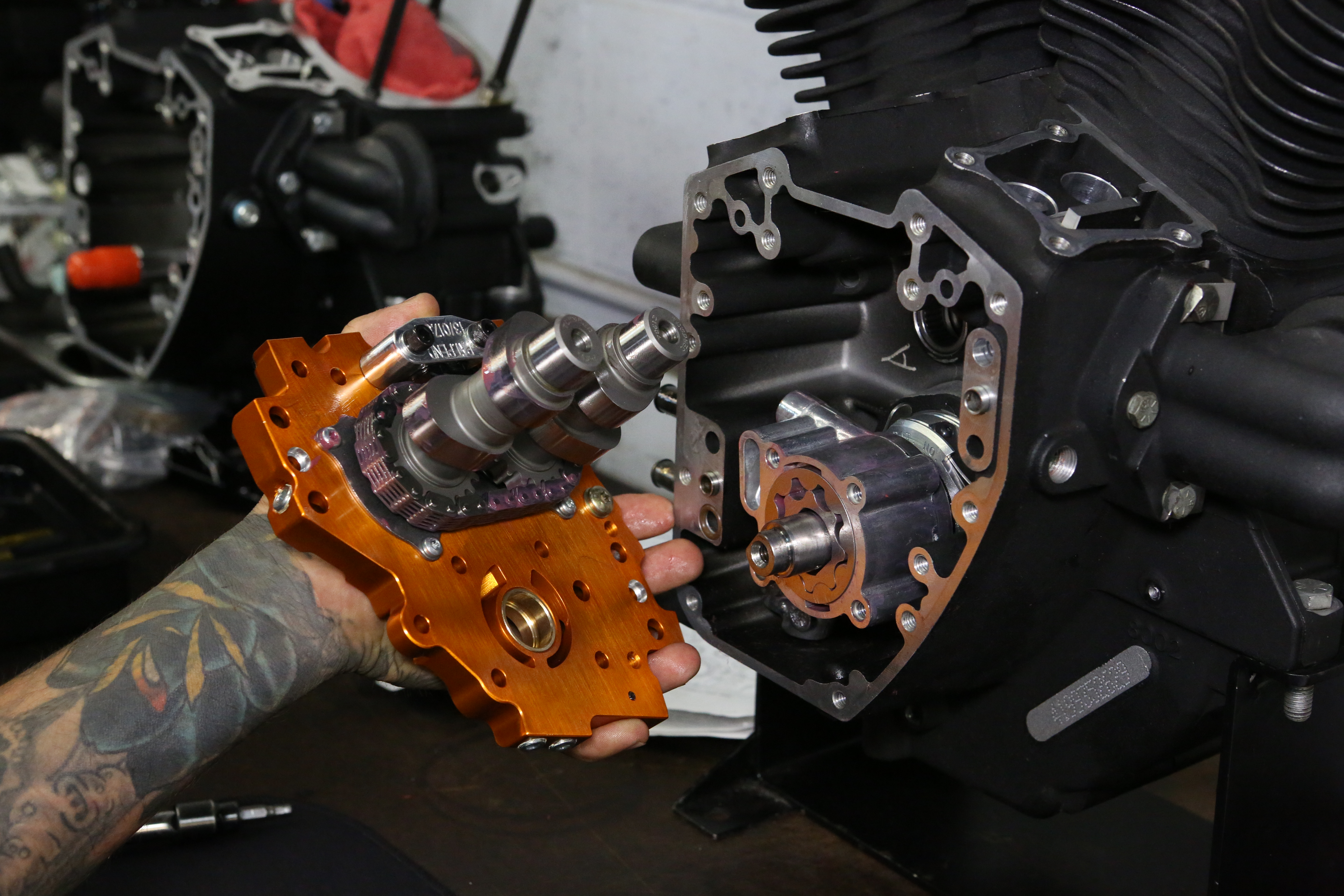

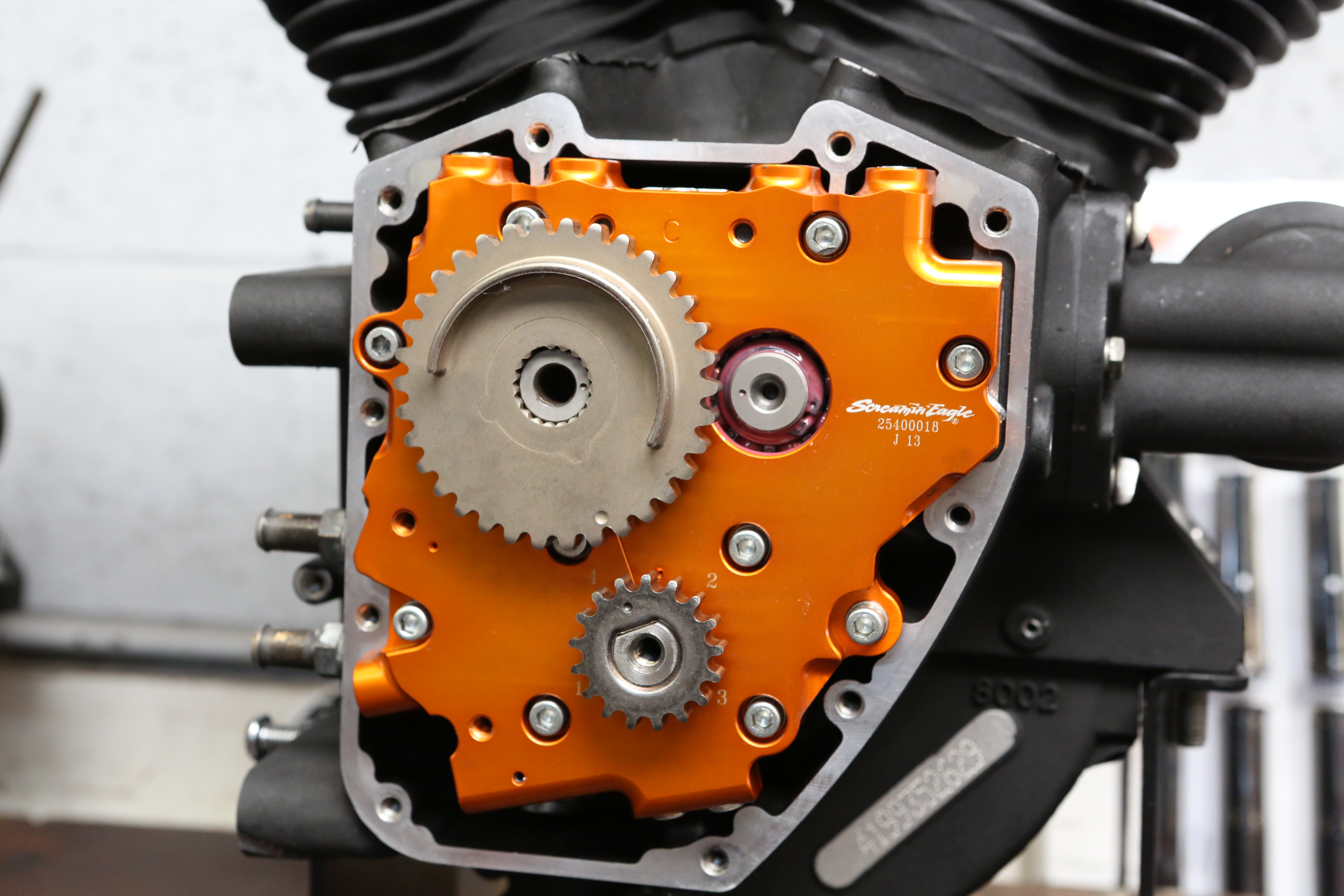

Using a press and our trusty JIMS cam bearing installation tool, we set up our camplate according to the service manual specifications.

Photo: Hot Bike Staff

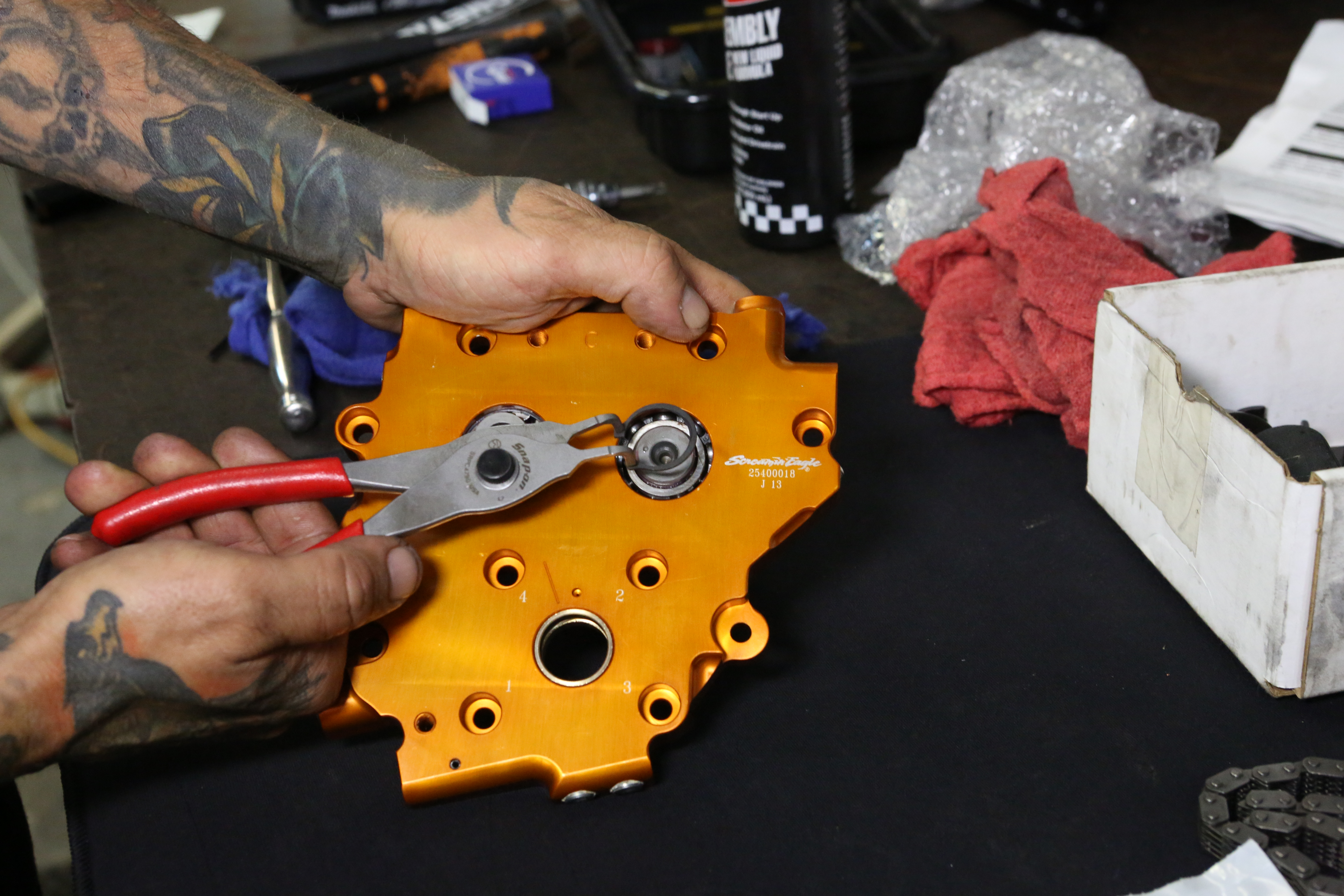

Install the snap ring to secure the cam in its proper position.

Photo: Hot Bike Staff

A coating of assembly lube helps to keep things smooth upon start-up.

Photo: Hot Bike Staff

We are using hydraulic cam chain tensioners from Zipper’s Performance. Here you can see the rear cam chain tensioner installed.

Photo: Hot Bike Staff

Take the camplate and install it into the cam chest of the engine case. Be sure to install new O-rings where required.

Photo: Hot Bike Staff

Install the cam plate screws and torque to 90 to 120 inch-pounds, and then install the oil pump alignment pins in the appropriate oil pump screw holes.

Photo: Hot Bike Staff

Follow the torque sequence procedure carefully; over-tightening or misaligning the oil pump can cause catastrophic engine failure.

Photo: Hot Bike Staff

Using an H-D cam spacer kit, find the appropriate spacer your camplate requires to have your cam chain sprockets in alignment.

Photo: Hot Bike Staff

Install the cam chain sprockets and you can tell if your spacing is close to being correct.

Photo: Hot Bike Staff

Sources