Twin Cam B-Motor Balancer Mods

1. Here are the balancer components from a JIMS 120ci TC B-motor, which are the same for a stock motor. At bottom is the cast aluminum chain guide support assembly with two hydraulic chain tensioners and three black chain guides. On the far left and right sides are the counter-rotating balance shafts. The roller drivechain and sprockets are in the middle. At the top are the two triangular balance shaft supports with ball bearing.

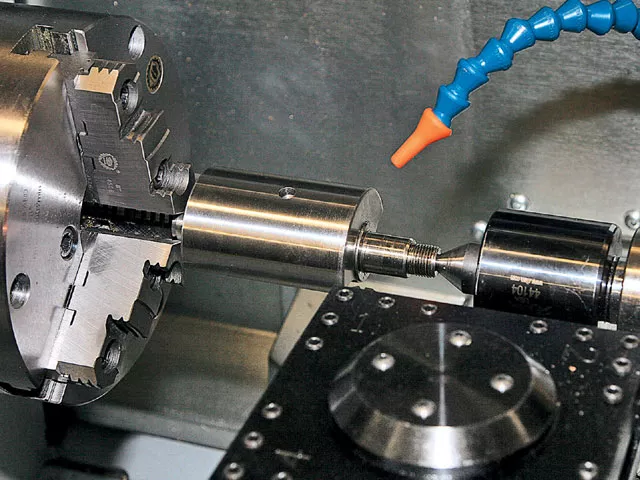

2. Charlie lightens the steel balance shafts by mounting each one in a lathe and machining material off the outer circumference. Stock units are balanced to within +/- 2-3 grams. Charlie balances the shafts to even stricter tolerances.

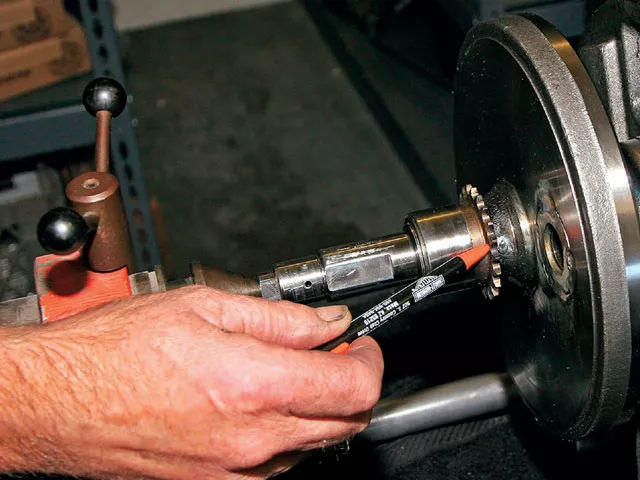

3. The balancer shafts’ chain drive sprocket is a press fit on the crank’s pinion shaft. The drive sprocket can slip on the pinion shaft, throwing the engine out of balance. Charlie checks the sprocket’s index and then TIG-welds it in three places for a secure fit.

4. Shown is the TIG-welded balance shaft drive sprocket on a stock B-motor 4-3/8-inch stroker crank. Charlie checks the crank for true after welding and, if necessary, can service a shifted crank.

5. A serviced crankshaft assembly is trued to within .0005 inches when checked at both ends of each mainshaft.

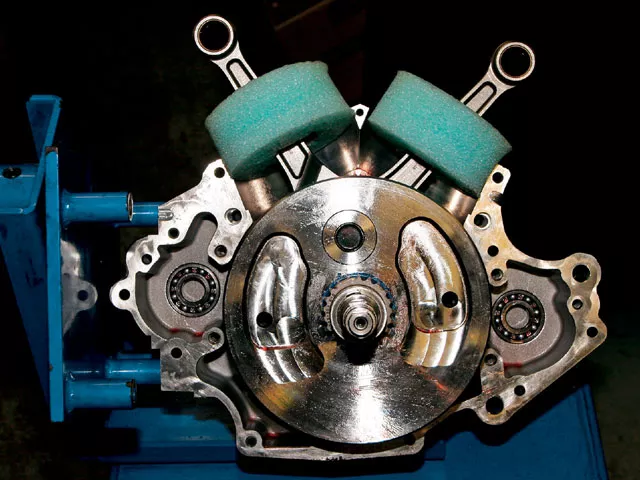

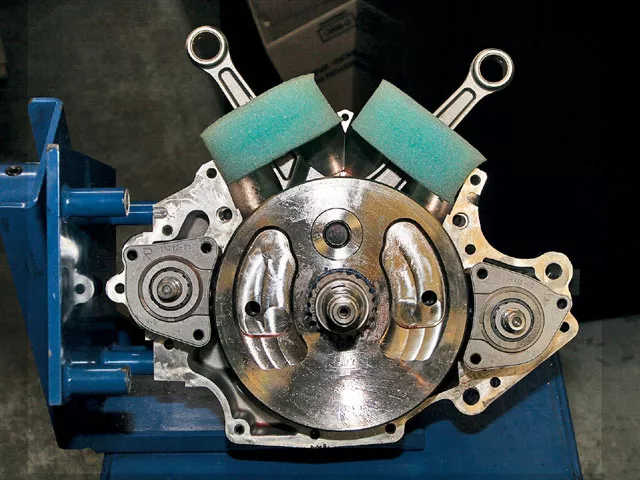

6. Shown is a JIMS 120ci B-motor. Charlie disassembled the engine’s bottom end to lighten the balance shafts. Note the fore and aft counter-balance recesses (red arrows) and ball bearings for the balance shafts (blue arrows). Assembly of the counter-balance system starts by installing the flywheels into the left case Timken bearing.

7. Next, the balance shafts are installed in the fore and aft ball bearings in the left case (red arrows). The shafts are identical and interchangeable.

8. Now, a triangular balance shaft support is installed on the end of each balance shaft (red arrows). Each support includes a ball bearing that supports the right side of the balance shaft (blue arrows).

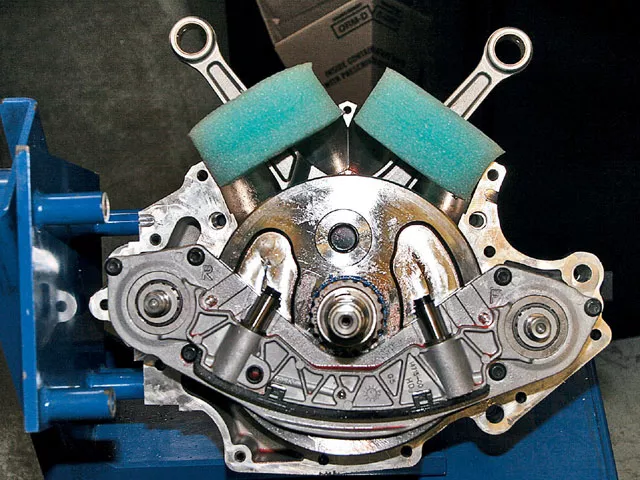

9. The large chain guide support is now installed on the triangular balance shaft supports and secured with six bolts (three per support). The six bolts secure the two balance shafts, two supports, and the chain guide support to the left case.

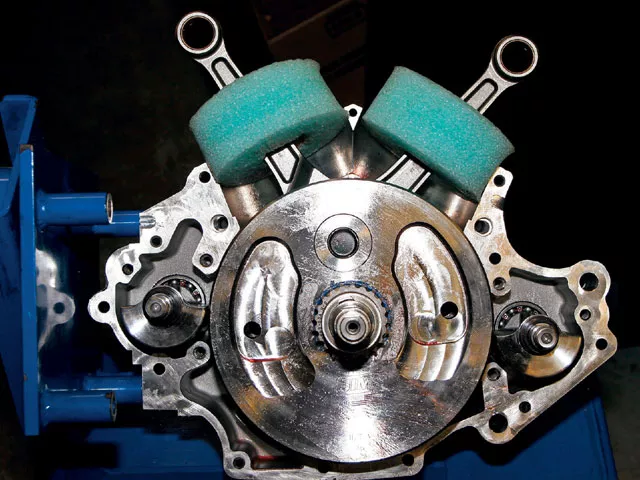

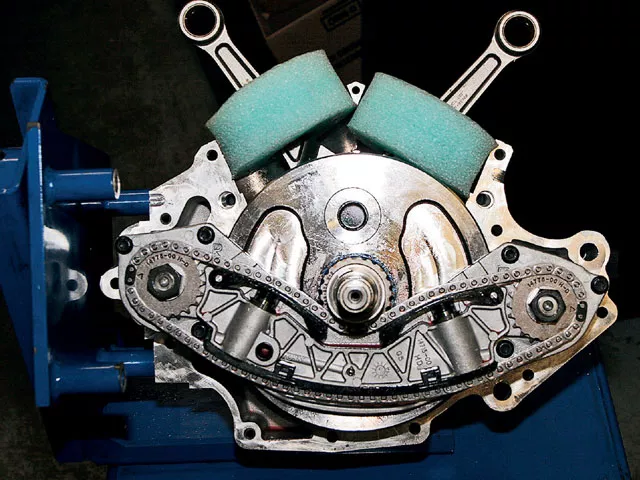

10. Next, the two hydraulic chain tensioners are compressed using red factory assembly clamps. The two top chain guides with an internal leaf spring, balancer drive chain, and shaft sprockets are then installed.

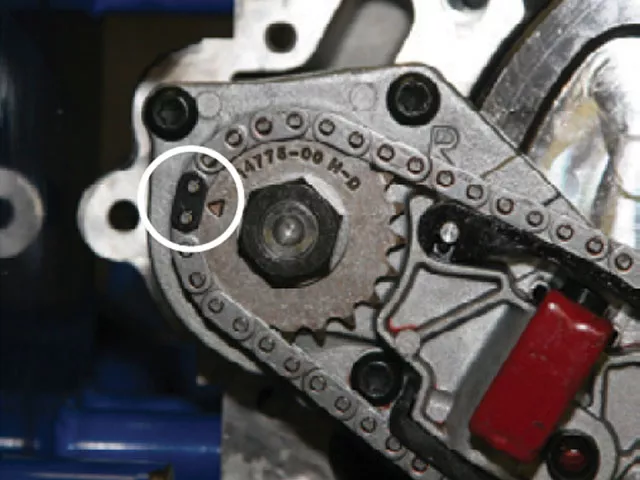

11. To ensure the balance shafts are timed correctly, the three black-colored plates on the roller chain are aligned with the triangular timing marks on the three sprockets. The two balance shaft sprockets are marked “front” and “rear” and are not interchangeable.

12. Shown is the roller chain’s black-colored timing plate aligned with the timing mark on the crank’s chain sprocket.

13. The two red factory assembly clamps holding down the hydraulic tensioners are removed, revealing the B-motor’s completed balancer assembly. Note that the drive chain wraps under the crank sprocket.

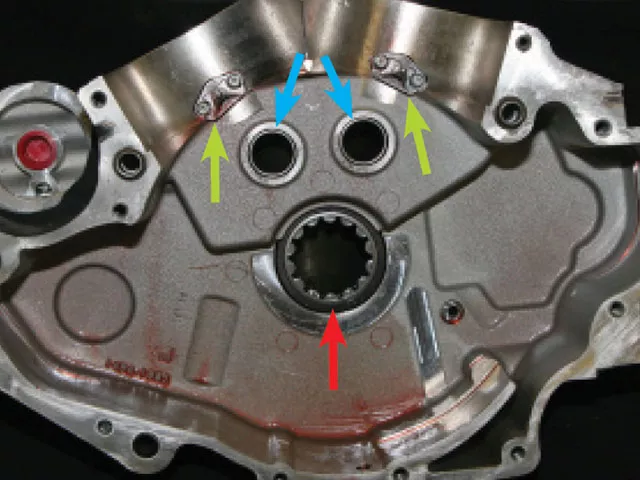

14. Shown is the flywheel cavity of a right-side B-motor case. The large roller bearing in the middle (red arrow) supports the crank’s pinion shaft, the two smaller bearings (blue arrows) above it support the left side of the camshafts. Above the cam bearings are two piston oilers (green arrows) fastened to the case cylinder spigot bores. ThreeBond Liquid Gasket 1194 is used for sealing the cases.

For the 2000 model year, Harley-Davidson introduced a redesigned Softail frame. To maintain the visual styling of the Softail models, Harley knew that the Softail’s engine had to be solid-mounted. Harley also knew that a solid-mounted Twin Cam 88 engine would create too much vibration. The Factory’s solution was the new Twin Cam 88B motor.

The Twin Cam B-motor differs from an A-motor in that it has two counter-rotating balancers, one fore and aft of the flywheel assembly, that, together with the flywheels, negate nearly 100 percent of the engine’s primary vibration. The two balancers are connected to each other and the crankshaft by a roller chain. The flywheel’s pinion shaft and each rotating balance shaft have a chain sprocket with a timing mark that must be aligned to correctly position the balance shafts and flywheels for proper engine balance.

The drivechain is kept in adjustment by two hydraulically operated chain tensioners. The engine’s oil pump feeds oil to the hydraulic tensioners through a special oil galley. Three plastic chain guides, two top and one bottom, keep the drive chain running in a smooth arch. The B-motor’s crankshaft assembly is the same as an A-motor’s, except for the right flywheel/pinion shaft unit and the addition of a chain drive sprocket, which is pressed onto the pinion shaft. The entire counter-balancing system adds about 14 pounds to the engine.

For the most part, the Twin Cam B-motor counter-rotating balancer system is relatively maintenance free. However, under certain conditions the chain drive sprocket pressed on the crank’s pinion shaft can slip, throwing the balance shafts out of alignment and the engine violently out of balance. Additionally, when riding on the street and suddenly closing the throttle, a B-motor can cause a “pushing” effect, which can require more braking than desirable.

Charlie Lawlor of Short Block Charlie’s in Tempe, Arizona, has developed two modifications that fix both balancer problems while improving engine acceleration. To address the engine’s out of balance problem caused by the drive chain sprocket slipping out of alignment on the crank’s pinion shaft, Charlie TIG welds the chain sprocket to the shaft. To eliminate the engine’s “pushing” effect, Charlie reduces the weight of the steel rotating balance shafts and matches their individual weights to closer than Factory tolerances. The two modifications smooth out the engine, allow for faster acceleration, and reduce the “pushing” effect while providing a more durable and worry-free engine.

Charlie can perform these worthwhile modifications on a new “crate” engine, used engine, or engine damaged with skewed balancers or a shifted crank. Of course, since the crankcase must be disassembled, these modifications are best done when doing major performance work like installing a stroker crank or big-bore cylinders requiring case machining. For additional information on building a bullet-proof bottom end, check out the companion article in this issue of HOT BIKE that explains how to improve bottom end durability by installing a left-side Timken bearing in ’03 and later Twin Cam engines.