Transform Your Stock Wheel – Hot Bike Tech

Wheel Works is located in Garden Grove, California, and has been family owned and operated since 1976. These guys know their stuff.

Here is the stock wheel suffering what Wheel Works guys call the “custom un-lacing” process. The stock 21X2.15 wheel was transformed to a wider 21×3.5 in a very timely manner so that Ox could get back out on the road and ride.

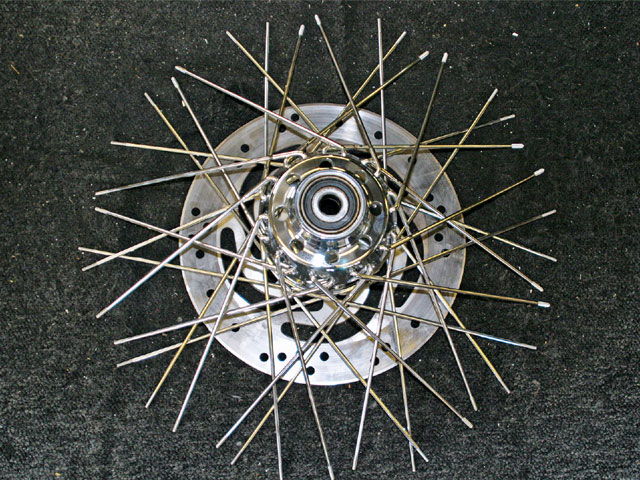

With a new Wheel Works rim and new laces, the guys at Wheel Works were kind enough to throw in a new front rotor as well. Before assembling the new components and lacing the wheel, the hub was polished to a pristine condition. Adam used super-fine steel wool to polish the hub, accompanied by a multi-purpose Protect All cleaning solution.

Wheel Works supplied the new rim and laces, and Ox decided he wanted a Metzeler ME 880 Marathon 120/70/21 tire. The original hub was used to tie up the rim with the new laces.

With this specific wheel, a mismatching lacing index was used (bottom inner/outer laces go in the same direction as top inner/outer laces) instead of a matching index (outer/inner laces cross at top and bottom). It depends on what kind of cross-pattern you are utilizing (four-cross, five-cross, etc). Adam used some lube on the tips of the laces where they met the rim so that when he tightened them up to the rim with the screw gun they wouldn’t bind or break. Wheel Works recommends tightening up the inner laces first, then moving to the outer laces, then repeating by going back to the inner laces and once again back to the outers. Finished!

Adam laced the hub with the polished stainless spokes first in a cross-four pattern (each lace runs across four spokes then attaches to the rim for stability and strength). On the outer part of the hub, which meets the rotor, there are both inner and outer holes to be laced to the inner/outer holes on the rim. On the inner part of the hub there are two more sets of inner/outer holes that will be laced with the outer part of the rim.

Once Adam finished the lacing, it was time to let Gary, co-owner of Wheel Works, put the new wheel on the truing machine. Truing is a key component to a rider’s safety. If the wheel is not true, side-to-side wobble occurs. Gary tightened up each lace one by one after he lubed up the nipple and rim on the truing machine. He then placed a scribe indicator, which tells him what lace needs to be tightened up and what needs to be loosened to make the wheel true. When a specific area of the rim touches the scribe he knows he has to tighten that area more, and when the rim pulls away from the scribe he has to loosen it. This is a very tedious process, but Gary has been doing this for years and is an expert.

Once the wheel spun true, Adam ground the excess of the threads of the spoke laces sticking out of the rim. This isn’t an abnormal practice, and after the grinding was completed the inside of the outer perimeter of the rim was wrapped with a rim band to safeguard the tube from being punctured.

The new rotor was attached, and before Adam installed the new tube, he soaked the outside of the new tire with soap and water to make for easier installation, and to double-check that the tube didn’t leak.

Then he installed the tube on the tire machine, and once that was completed he put it on the wheel balancer for proper weight distribution. Before he could install the new wheel, the front fender had to be removed to compensate for the extra width of the new wheel. Once he was finished, the bike was rolled out to its rightful owner to get back on the road.

Notice the difference in width (stock wheel is on the left). It may not be the most impressive difference looks-wise, but shortly after the installation we checked back with Ox to see how the new wheel/tire combo was working out and he told us that he absolutely loves the new setup and that it made a night and day difference on the highway because it handled more solidly and didn’t track in the rain grooves. Well, we’re glad it made such a difference, mate. See you out on the highway.

Freeway riding isn’t the most desirable way to get from point A to point B, but let’s face it, sometimes it’s inevitable. One of the biggest problems that riders face with highway riding are rain grooves, which are put in place to prevent roads from flooding or pooling up with excessive water. And with a 21×2.15-inch front wheel and 90/90/21 tire combo as the standard on many of the Softails on the road, the narrow width of the wheel plays a factor in maneuverability because of the wheel’s tendency to track into the rain grooves at high speeds. It can alter your travel path and make it feel like you’re locked into the road, and everyone who’s encountered this knows it will leave you with a foul taste in your mouth. We found a gentleman by the name of Ox with an ’06 Night Train who was looking for a solution to his front 21×2.15-inch, 40-spoke wheel problem. We rang up the boys at Wheel Works and asked if they could help our buddy Ox by widening the wheel to a 21×3.5-inch rim and adding a 120/70/21 Metzeler tire, but still utilize the stock hub and 40-spoke application. They were more than happy to help out. Now, we know what you’re probably thinking: What is the big deal about widening your front wheel? According to Ox, “This is probably the best thing I’ve done to my bike since I’ve owned it!” With that said, read along as we take you step by step on how one would go about widening the front wheel.