Tech | 88ci to 124ci Mega Motor Mechanics

S&S Cycle 124-Inch Hot Set Up Kit install Part 1

Photo: Jeff Holt

At Hot Bike we are always on the quest for more horsepower. Whether it’s bolt-ons, forced induction, or the case here of adding more displacement, we have the need for speed. Take this 2005 88-inch H-D Twin Cam motor for instance. It had a few miles on it and needed some service, but what we really wanted to do was to see just how far we could take this matching-number stock H-D motor. We contacted S&S Cycle, and after much discussion the team agreed to send us one of their 124-inch Hot Set Up kits to install. Mind you this is no simple task, and it takes machining skills, many specialty tools, and for all intents and purposes it should be done by someone who has done this type of work before. This is why we enlisted Phoenix, Arizona’s Danny Wilson, a.k.a. the Motor Witch for the job. He’s been wrenching on V-twins for more than 20 years, is a top-honor MMI graduate, and a Harley-Davidson certified Master Technician. Once we nailed a date down we trucked on out to Arizona and got to work on making this little V-twin a fire-breather. Check it out!

Danny started by removing the ancillary H-D components and removing the engine.

Photo: Jeff Holt

Now it was time for disassembly of the stock 88-inch motor.

Photo: Jeff Holt

Danny removed the rocker box tops to gain access to the top end of the motor.

Photo: Jeff Holt

The new 124-inch cylinder heads will be dramatically larger than these stock jugs.

Photo: Jeff Holt

The stock pistons and rings were removed.

Photo: Jeff Holt

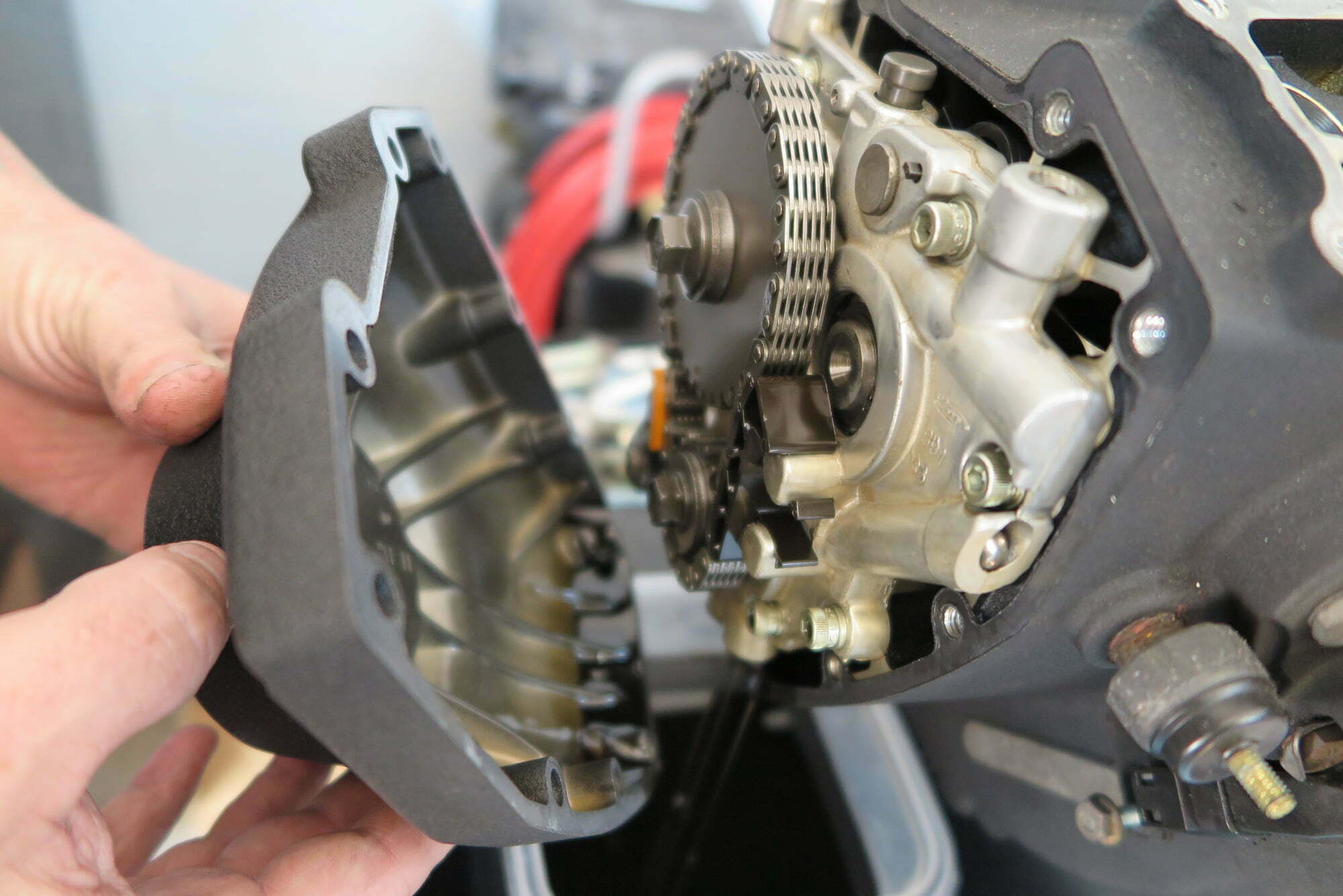

The cam cover was removed to gain access to the stock cams and camplate.

Photo: Jeff Holt

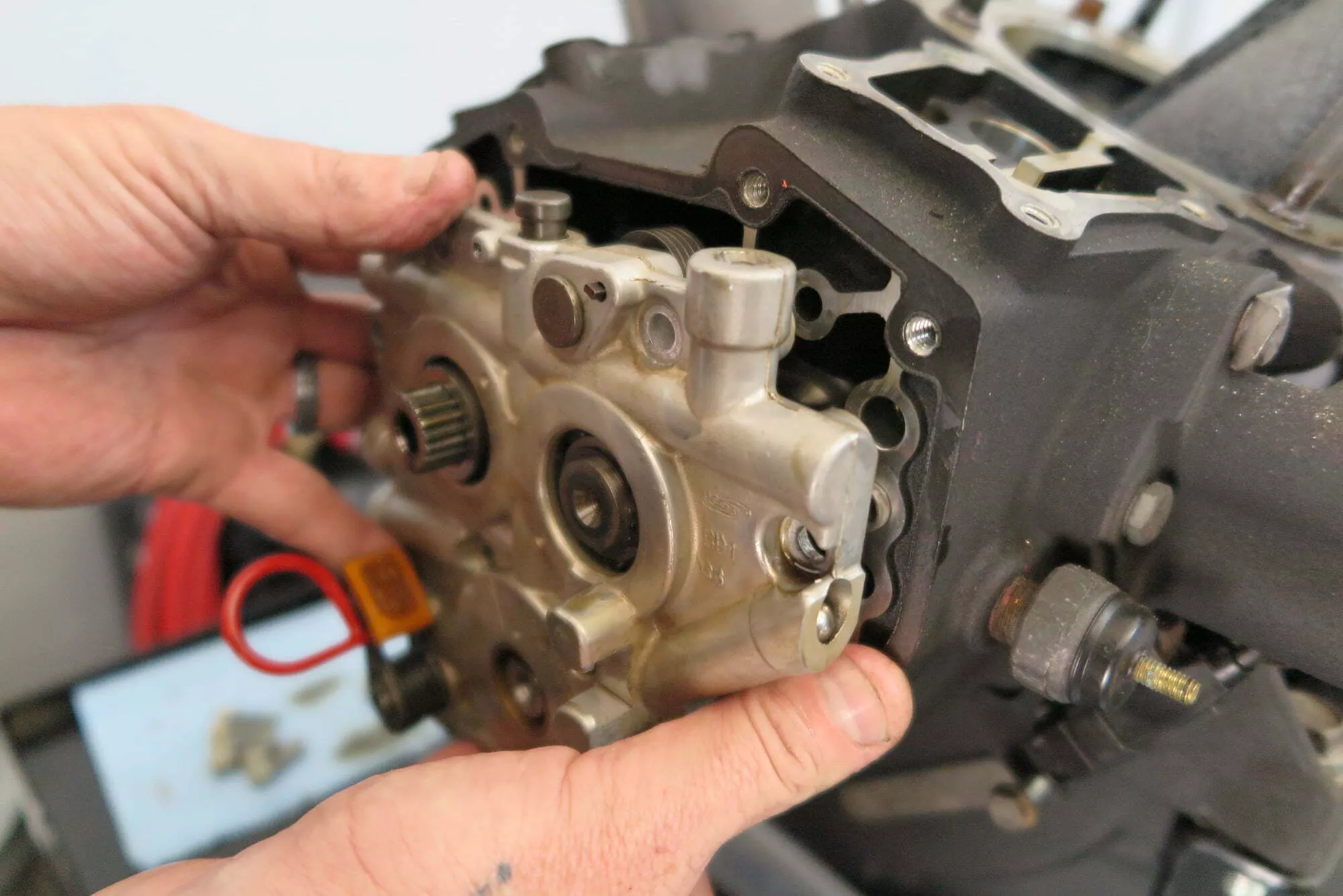

The cams and camplate were carefully removed.

Photo: Jeff Holt

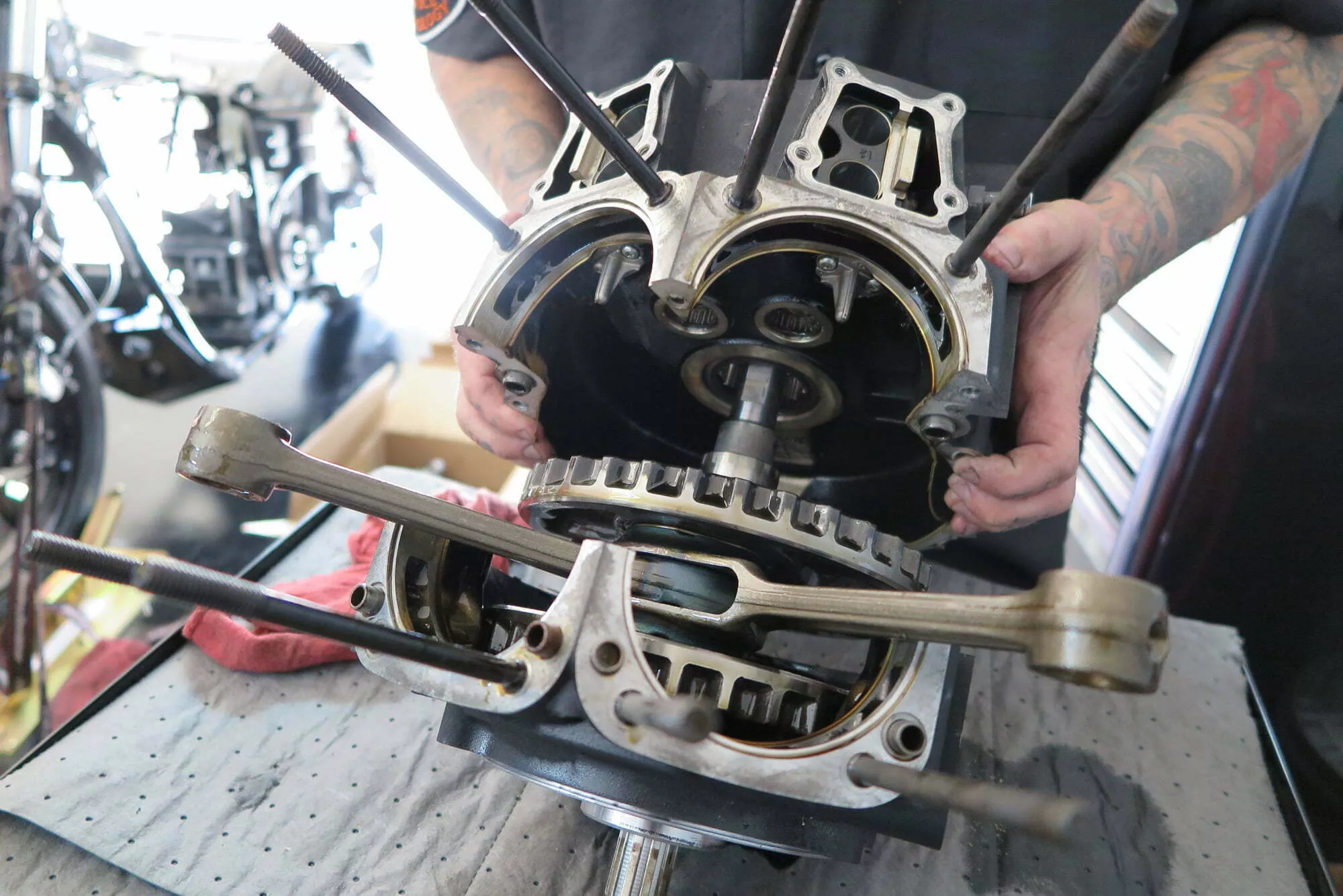

The cases of the engine were split to gain access to the stock flywheel.

Photo: Jeff Holt

Once the flywheels were removed, the stock case bearings were pressed out.

Photo: Jeff Holt

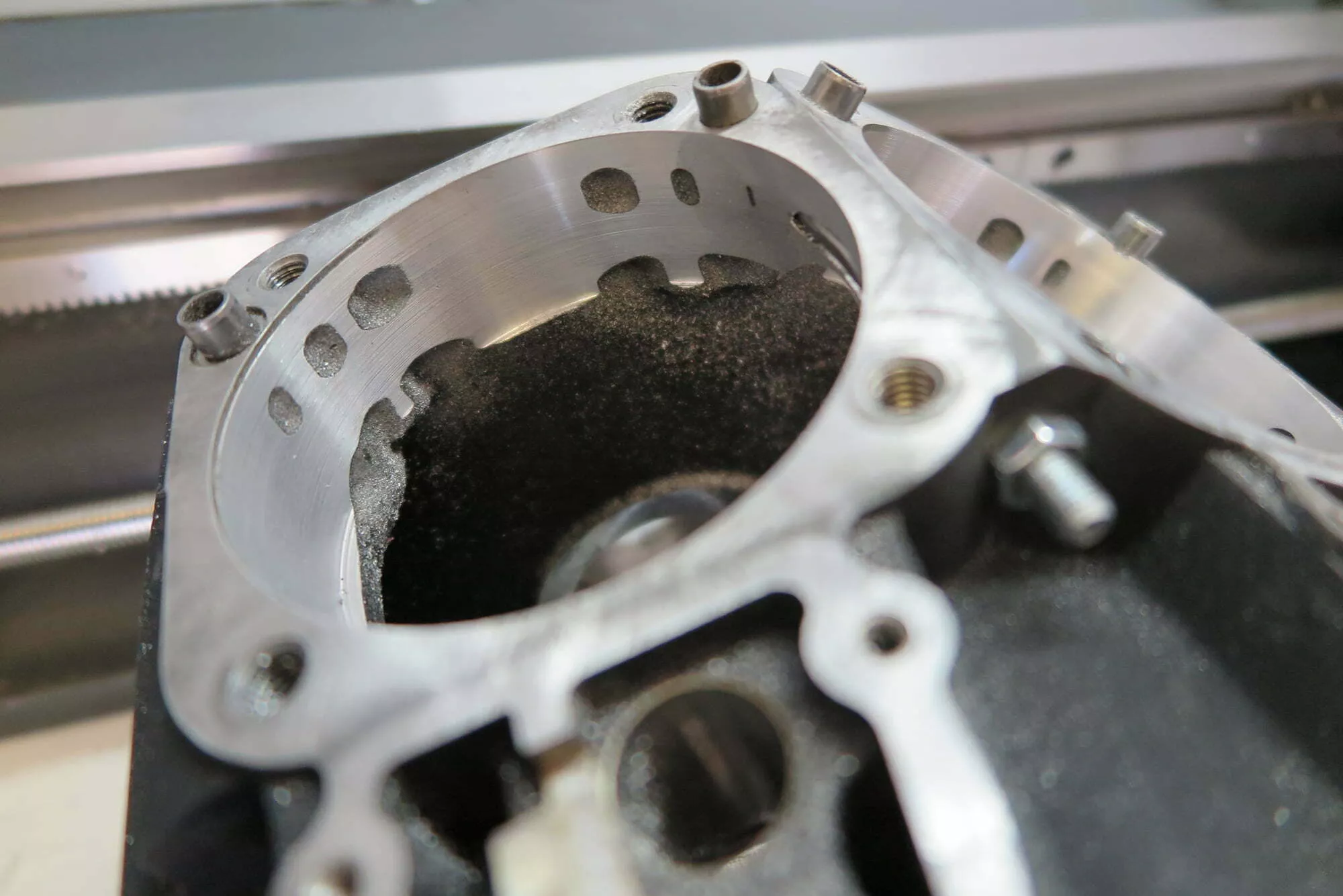

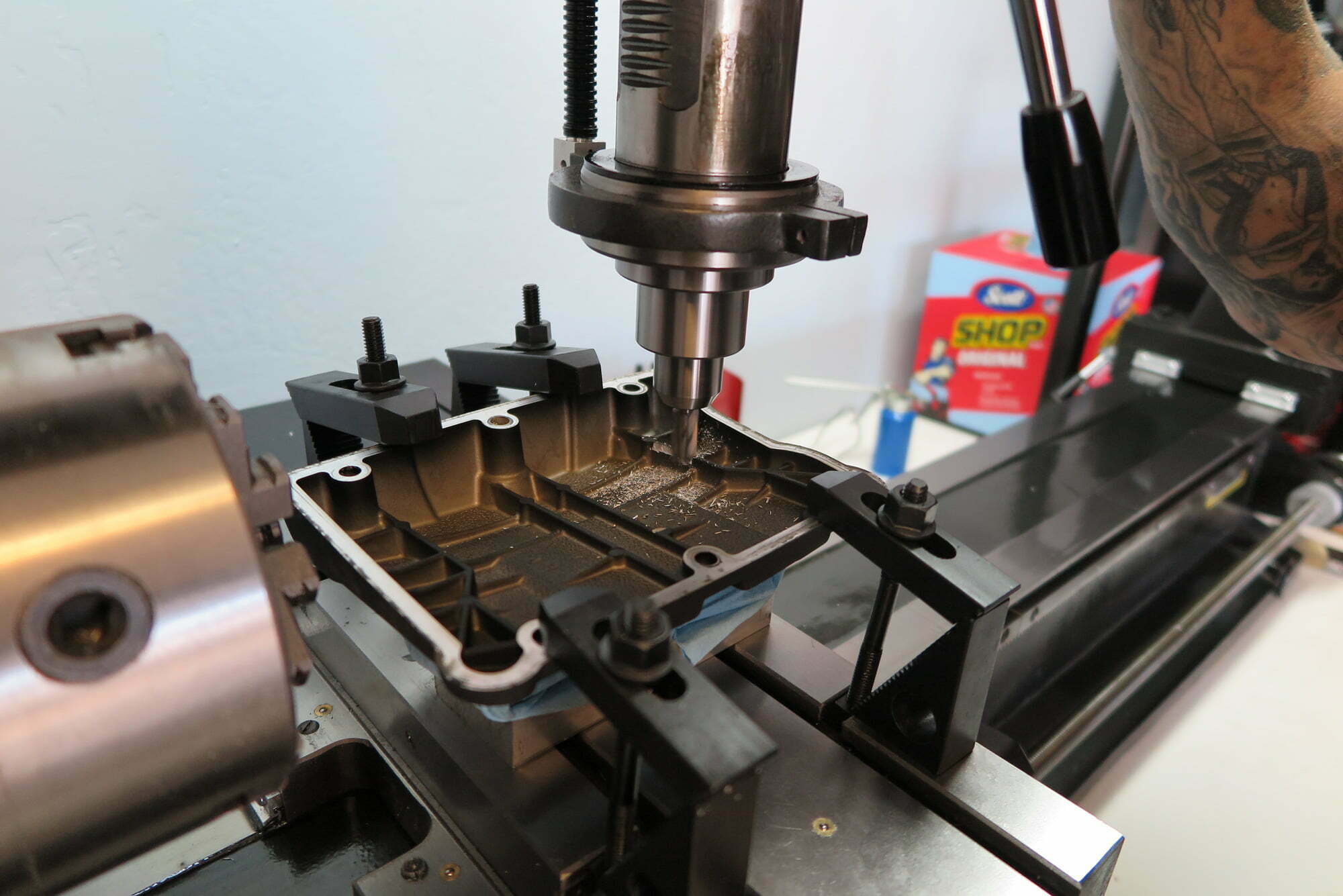

The top bolt hole of the case had to be bored out as per S&S’s directions.

Photo: Jeff Holt

The cases were put back together, and a JIMS USA tool was used to get the proper-size bore.

Photo: Jeff Holt

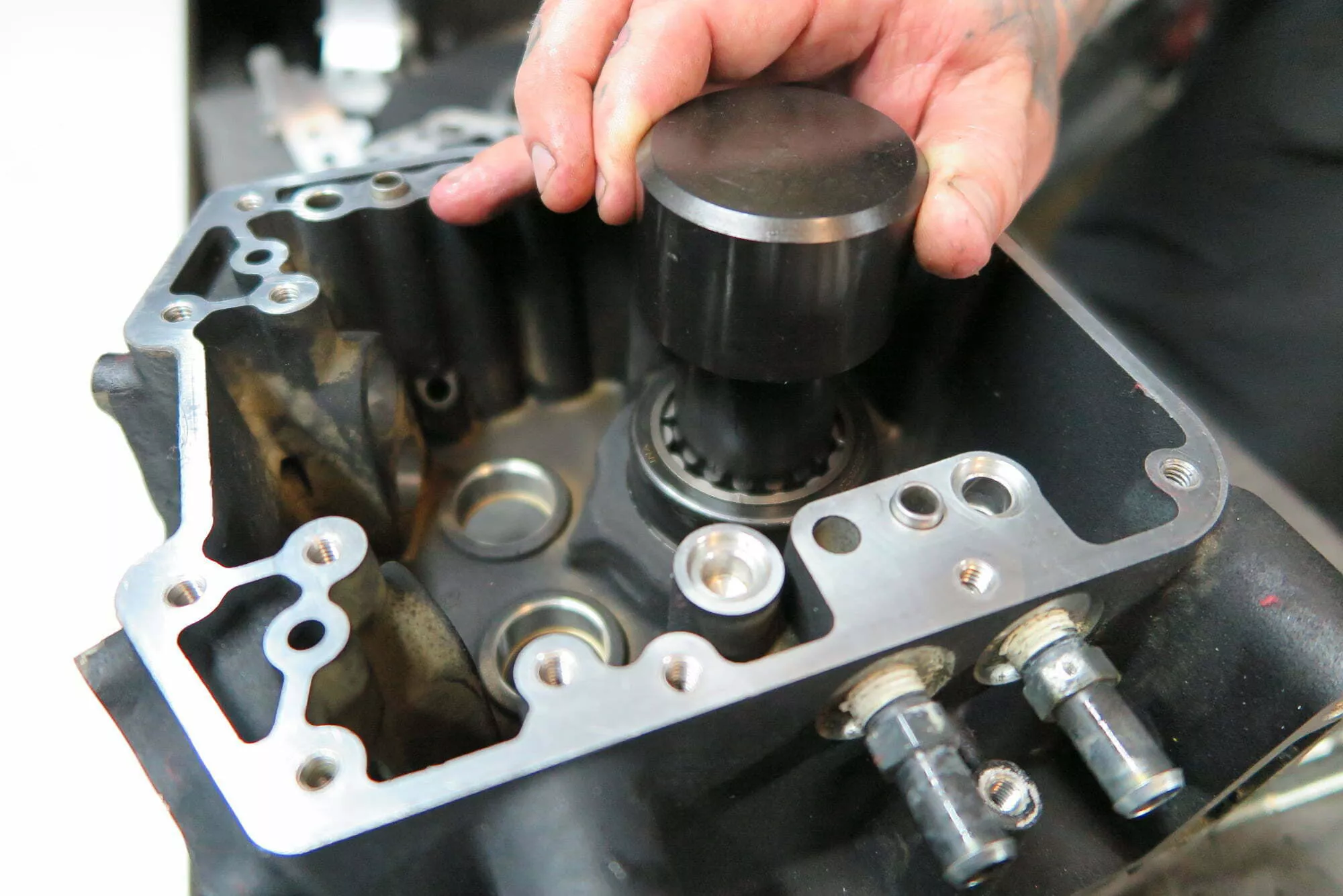

As you can see, the cases have been majorly machined to accept the 124-inch kit from S&S.

Photo: Jeff Holt

We took time to machine to rocker box tops to alleviate any contact issue with the new roller rockers.

Photo: Jeff Holt

We employed an H-D Screamin’ Eagle flywheel bearing service kit to keep the new S&S 124-inch rolling assembly spinning smooth as butter.

Photo: Jeff Holt

Danny carefully pressed the bearing kit into the left-side case.

Photo: Jeff Holt

Here is the finished left-side case ready for the S&S Cycle 124-inch kit.

Photo: Jeff Holt

A new H-D bearing will also be used on the right-side case.

Photo: Jeff Holt

Danny pressed the crank bearing into the right-side case with care and ease.

Photo: Jeff Holt

New cam case bearings from S&S Cycle were also installed.

Photo: Jeff Holt

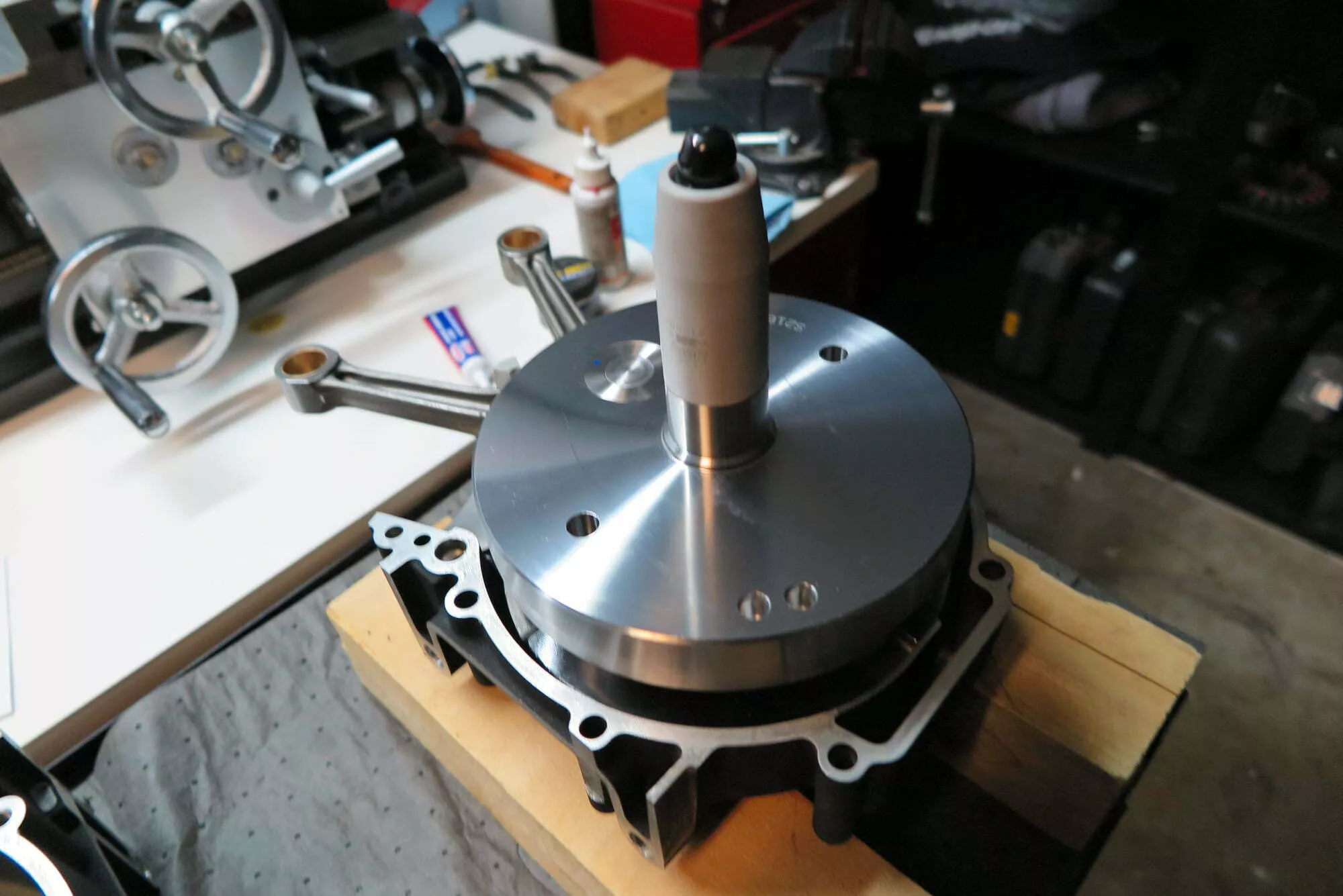

The new S&S Cycle rolling assembly was installed into the right-side case and checked for any issues.

Photo: Jeff Holt

Harley-Davidson High Performance sealant was liberally applied to the right-side case.

Photo: Jeff Holt

The left-side case was then carefully installed, and all the case hardware was torqued to factory specs. Excess sealant was removed at this time before it fully hardened.

Photo: Jeff Holt

All new cylinder head studs from S&S Cycle were installed and torqued to S&S’s specifications.

Photo: Jeff Holt

And the 88-inch to 124-inch engine’s bottom end is done. Check out the next issue for the top-end install and dyno numbers!

Photo: Jeff Holt

Sources

S&S Cycle

sscycle.com

JIMS USA

jimsusa.com

Harley-Davidson

harley-davidson.com

Get the all the latest issue of Hot Bike magazine! Subscribe directly from us.