S&S Cycle Hooligan Kit Installation Pictorial

We recently had our Sportster Hooligan flat-track racing bike’s engine freshened up with a Hooligan kit from S&S Cycle. The Hooligan kit is a bolt-on big-bore kit (increase 883cc engines to 1,200cc) with easy installation. No machining and no rebalancing are needed. S&S bolt-in cams and premium tappets are all part of the package.

We had T-Rod’s Speed Shop in Anaheim, California, install the kit with his vast engine rebuilding expertise. He applied some of his trickery including a three-angle valve job. While we had the engine torn apart we also installed an S&S flywheel assembly for the ultimate in Sportster performance. We’ll report back on how this bike performs after a proper break-in period. We are sure it’s going to rip!!!

For more info on the Hooligan kit and all S&S Cycle products, visit HERE

For more info and to contact T-Rod’s Speed shop, visit HERE

Our Sportster Hooligan racebike needed some freshening up on the engine. It was an 883 picked up on the cheap a few years ago then a low-dollar 1,200 kit was installed shortly thereafter.

After loads of miles on the street and plenty of full-throttle action on the track, it was getting a bit tired. So we went to S&S for some quality go fast V-twin engine parts and to T-Rod’s Speed Shop in Anaheim, California, for the build.

Photo: Ed Subias

The S&S Hooligan kit ready to install. We decided on installing a new S&S flywheel assembly into the lower end as well since the stock assembly was not within manufacturer

specs anymore.

Photo: Ed Subias

The S&S flywheel assembly.

Photo: Ed Subias

Cams are included in the Hooligan kit.

Photo: Ed Subias

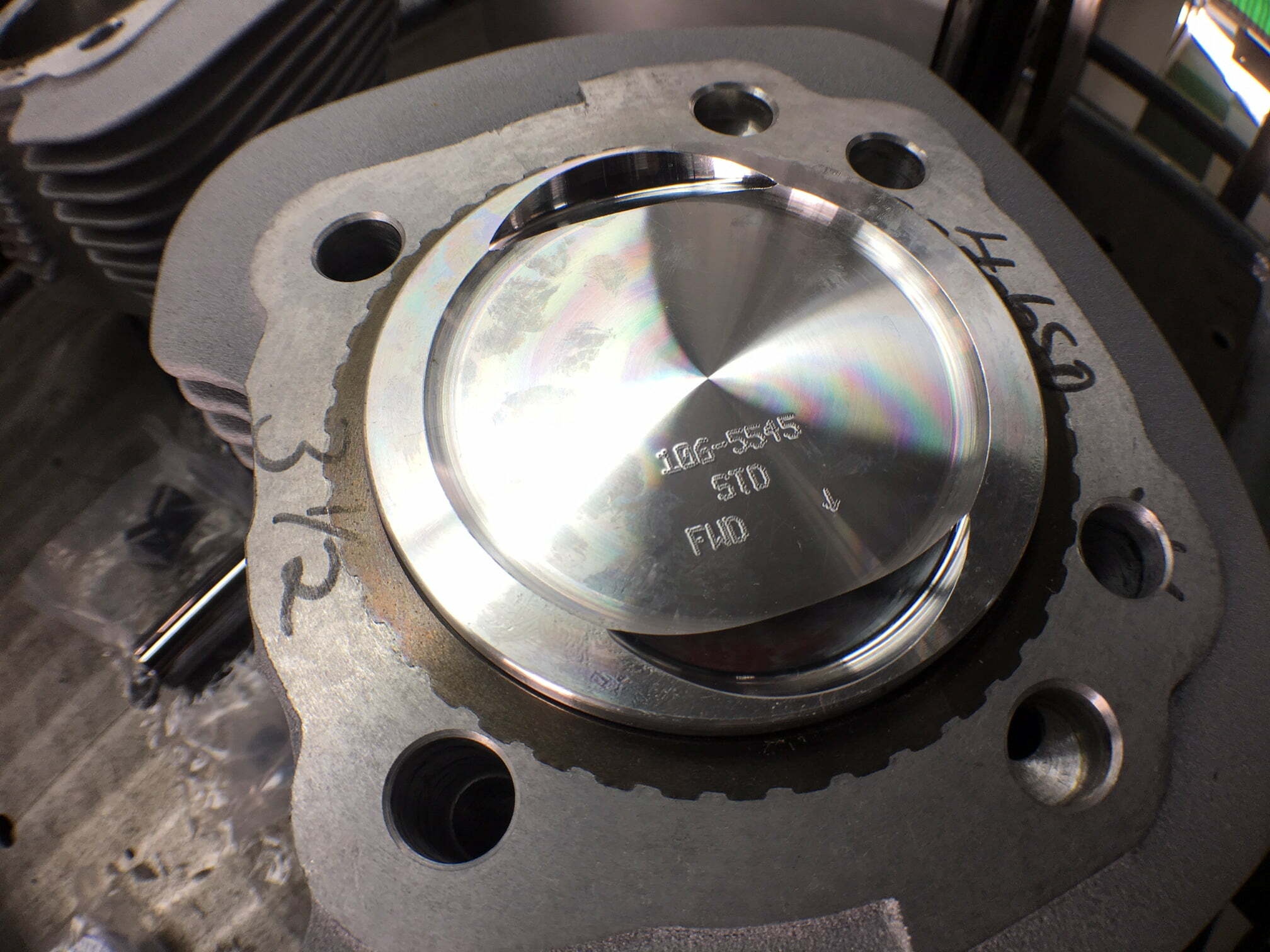

The S&S Hooligan cylinder and piston.

Photo: Ed Subias

The engine out of frame, ready to be disassembled.

Photo: Ed Subias

The engine out of frame.

Photo: Ed Subias

The lower end split.

Photo: Ed Subias

Old cylinders and pistons.

Photo: Ed Subias

The new flywheel assembly installed on the bottom end and bolted into the frame.

Photo: Ed Subias

T-Rod installing the pinion gear.

Photo: Ed Subias

The new flywheel assembly installed on the bottom end and ready for the top end.

Photo: Ed Subias

Parts laid out and ready for installation.

Photo: Ed Subias

The cylinders and pistons installed.

Photo: Ed Subias

The top end and cams ready to be installed.

Photo: Ed Subias

Marking the valve seat for a 45-degree cut.

Photo: Ed Subias

T-Rod preparing the valve seats for a three-angle valve job.

Photo: Ed Subias

The valve seat cutter.

Photo: Ed Subias

The three-angle cut on the valves.

Photo: Ed Subias

T-Rod assembling the valve train.

Photo: Ed Subias

Measuring to ensure proper valve train function.

Photo: Ed Subias

T-Rod checking that the spring tension is proper.

Photo: Ed Subias

T-Rod assembling the valve train.

Photo: Ed Subias

The front head going on.

Photo: Ed Subias

The heads with the valve train installed.

Photo: Ed Subias

Getting there.

Photo: Ed Subias

Just about done.

Photo: Ed Subias

Our Hooligan racebike ready to rip…

Photo: Ed Subias