Road King Stage 2 Kit Part 1

1. Here’s the complete Yuill Bros. Stage 2 kit. In the upper left is the MasterTune TTS interface and software CD not including the interface cables. In the middle is the exhaust system with the heat shields on the header pipes. In the upper right is the air cleaner with new backing plate and filter. In the lower right are the gear driven cams with adjustable push rods and cover tubes.

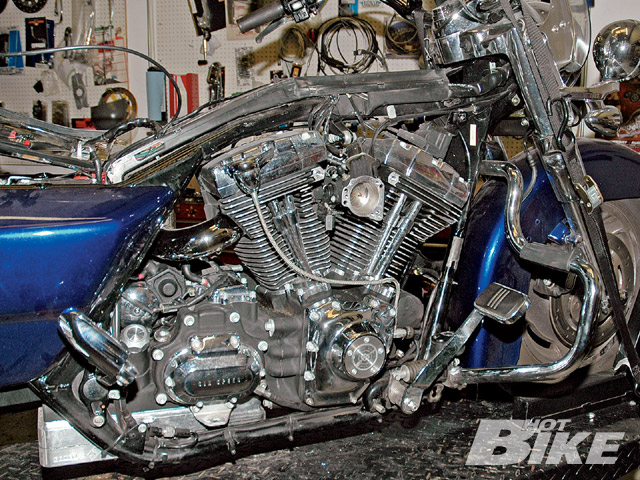

2. To install the gear driven cams, we headed over to Lucky Devil Metal Works where Brad Latham was going to perform the install. Once secured to the lift, Brad removed the seat, disconnected the negative battery cable, gas tank, air cleaner, right floorboard, front exhaust, and both spark plugs (so we can easily turn the engine with the rear wheel).

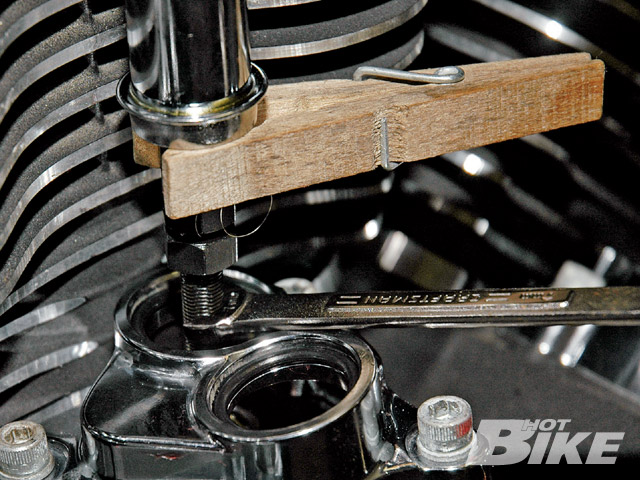

3. Brad cut out the old pushrods with bolt cutters. If you plan to reuse your push rods, you’ll have to remove the rocker boxes and take them out thru the top of the motor. Fortunately, Yuill Bros. included a new set of adjustable push rods.

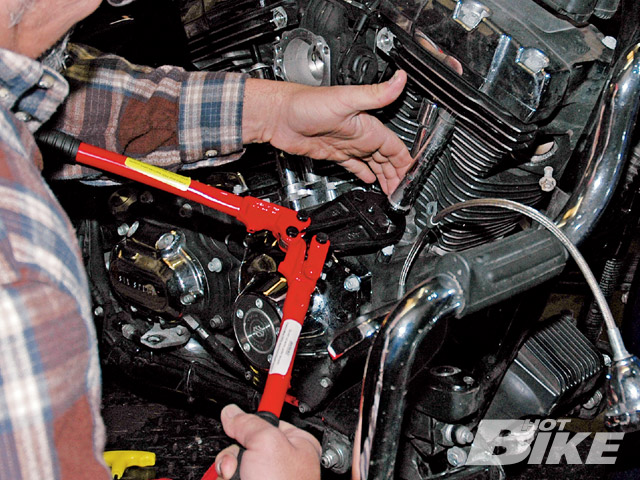

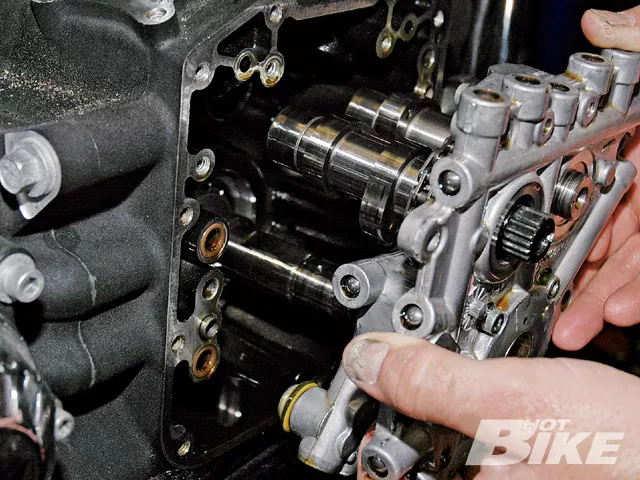

4. With the cam cover removed, Brad put the transmission into fifth gear, so he ould rotate the rear wheel until the cam timing marks were aligned. Then he inserted a pin (Brad fashioned one from a welding rod) into the hydraulic chain adjuster to hold in the internal spring, piston, and shoe.

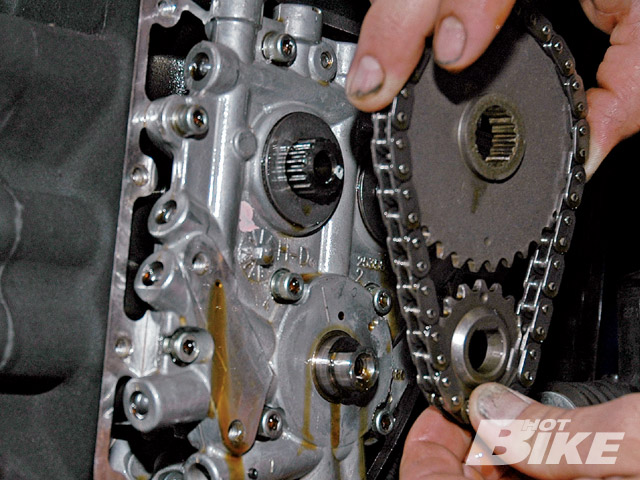

5. Next, Brad removed the retaining bolt from the crankshaft sprocket and the rear camshaft sprocket and slid them off. He set aside the retaining ring and washer on the front cam shaft to be used on the new front cam.

6. Brad removed the lifter covers followed by the lifters and then removed the cam support plate. The oil pump retaining bolts were loosened to permit correct oil pump rotor alignment when the cam support plate was reinstalled.

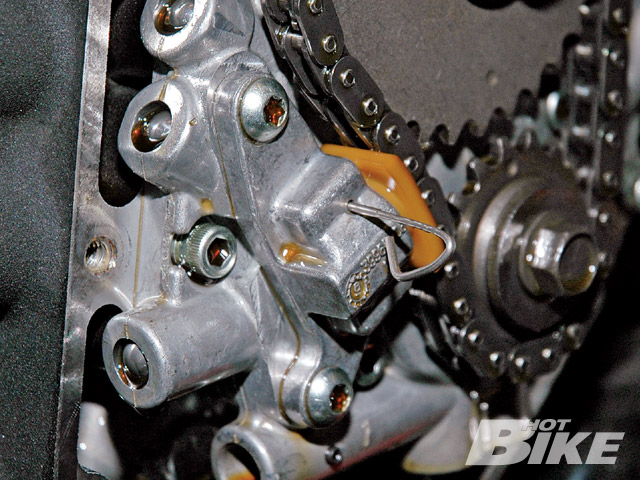

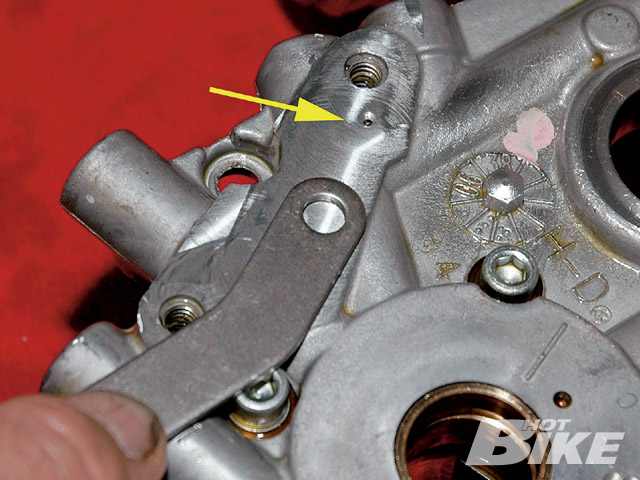

7. Brad inserted another pin into the inner hydraulic chain adjuster then removed it. Since the geared cams don’t use chain lubricators, the installation kit includes two oil port (yellow arrow) covers, which Brad installed.

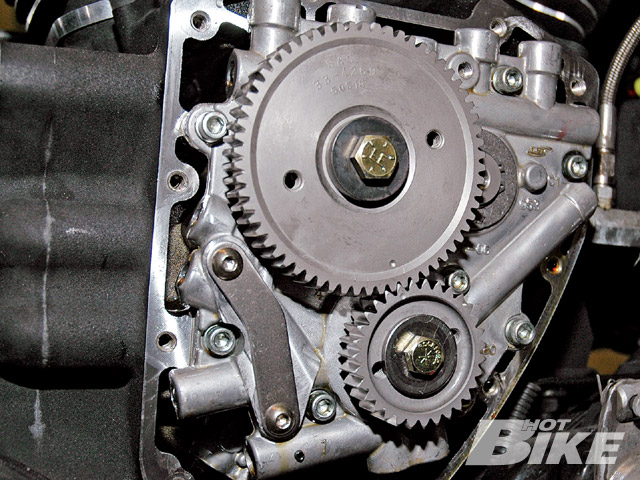

8. Brad pressed the drive gears onto each camshaft with the drive keys in place making sure that correct gear was pressed onto its corresponding camshaft (front to front, etc.) and that they were oriented per the instructions (gear shoulders facing the cam support plate).

9. Here is a comparison of the stock chain driven cams (left) with the new Yuill Bros. gear driven cams (right). Note the differences in the rise and width of the cam lobes.

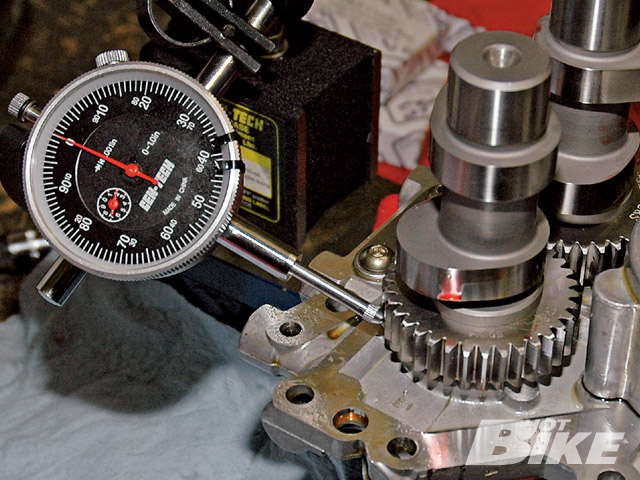

10. Brad aligned the timing marks on the cam gears and inserted the cams into the cam support plate. Here Brad checked for backlash in the cam gears. The cams should roll freely with no binding. However, some backlash must be present. Too little and the gears may bind, too much and the gears will be noisy. Ours were in the recommended range.

11. Brad then followed the poper sequence for reinstalling the cams/support plate. With the cams installed, Brad checked for end play and backlash. Similar to the cam gears, these gears must have some play.

12. Next, Brad inserted the four lifters and properly adjusted the new adjustable push rods.

13. Before installing the outer cam cover, Brad checked for gear clearance. Finding no issues, he installed the cover following the tightening sequence and torque in the service manual to complete the cam install.

14. Back in our Houston garage we worked on the air cleaner and pipe install. This close up photo shows how the air cleaner cover trap door works. When closed in rain or cold weather, intake air comes from the motor side of the cover. Also note how Yuill Bros thoughtfully added hand written instructions on some of the parts.

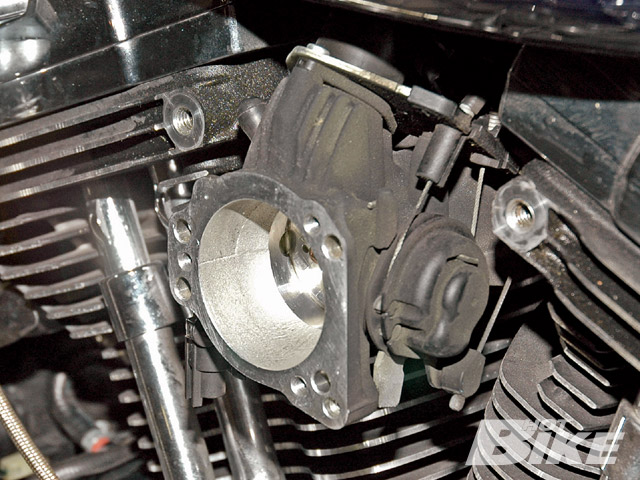

15. To install the new air cleaner, we completely removed the stock air cleaner, backplate, and breather bolts. We also took a second to clean the inside of the induction module with carburetor cleaner.

16. We installed the Yuill Bros supplied Screamin’ Eagle backplate by adding new o-rings to the backplate at the breather holes, loosely inserting the breather bolts, then attaching the backplate to the induction module with the supplied air filter posts. On all bolts, we used some blue threadlocker and torqued them to spec.

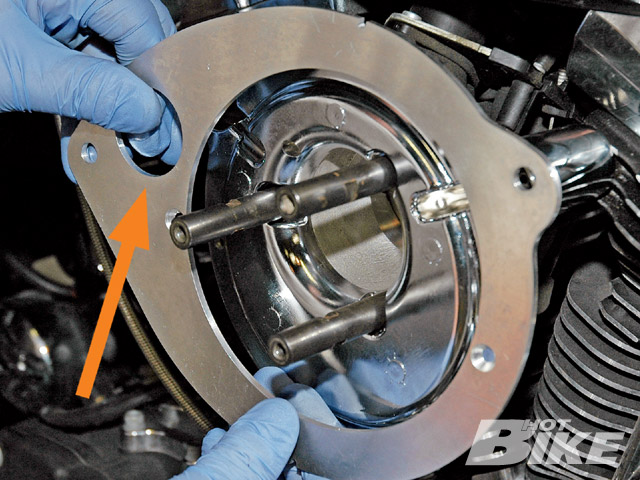

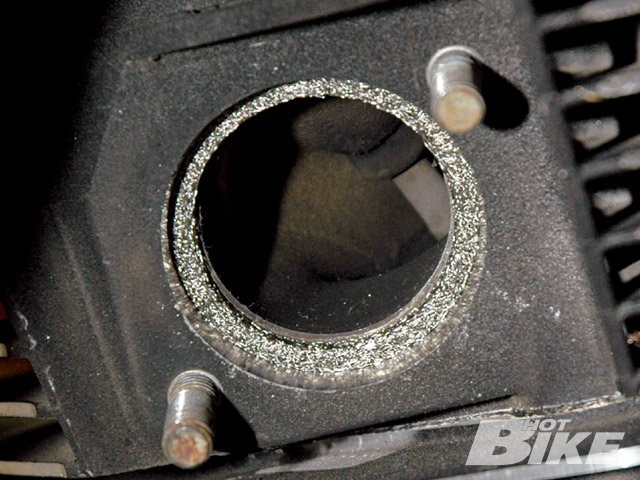

17. Next, we inserted the supplied rubber breather tubes into the breather holes and mounted the Yuill Bros plate to the SE backplate. Note the large hole in the rear of the plate to direct fresh air onto the rear cylinder (arrow).

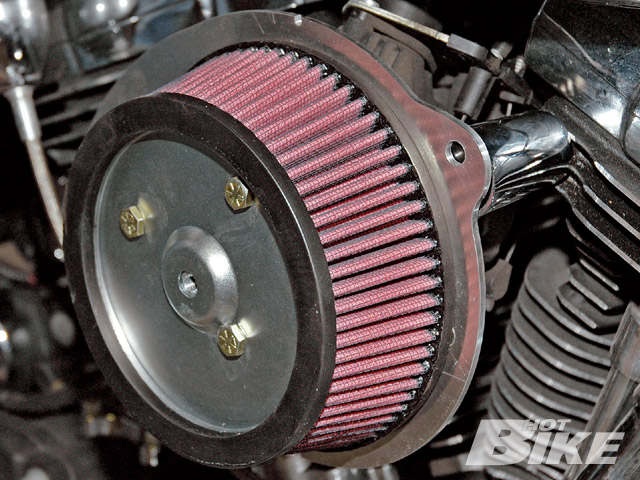

18. We attached the high flow air filter to the mounting posts with the supplied bolts.

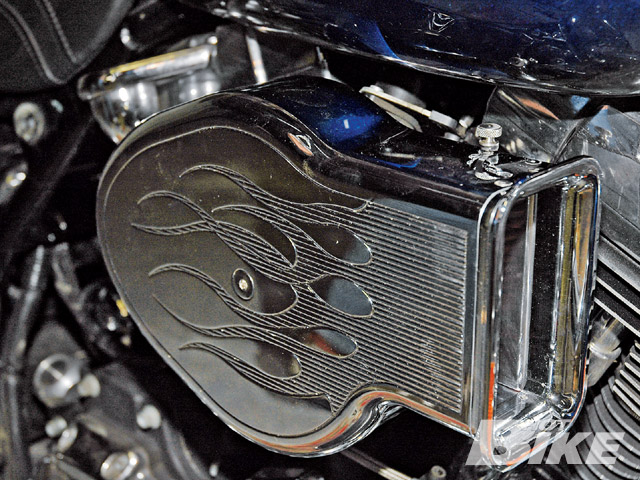

19. Finally we installed the chrome flame cover by aligning the dowel pins with the holes in the mounting plate and secured with the supplied center bolt. The Yuill Bros air cleaner is an attractive and highly functional addition that will draw attention.

20. To install the Yuill Bros Elite D Exhaust System, we first raised the bike and secured it. Then we removed the seat and disconnected the negative battery terminal. Next, we removed the saddlebags, the right side floorboard and brackets, and the complete existing exhaust system. Then we removed the existing exhaust port gaskets and installed new James gaskets.

21. Next, we transferred the OEM exhaust flanges, retaining rings and O2 sensors from the existing pipes (top) to the new Yuill Bros. headers (bottom).

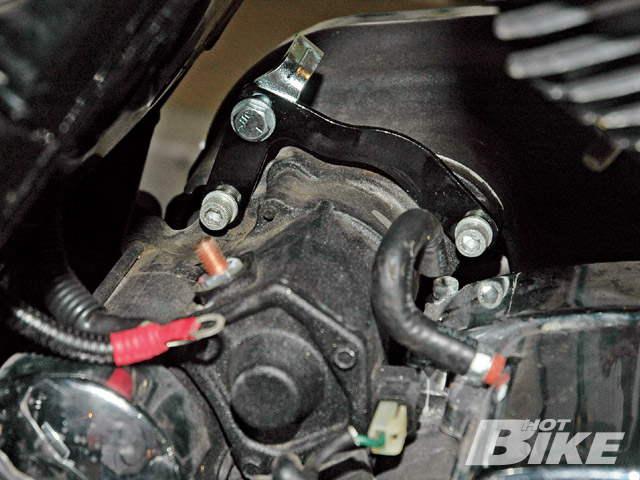

22. Then we removed the OEM starter bracket and installed the new starter bracket using the OEM bolts. Next, we installed the new “L” tab to the starter bracket and followed the instructions for the rest of the pipe installation.

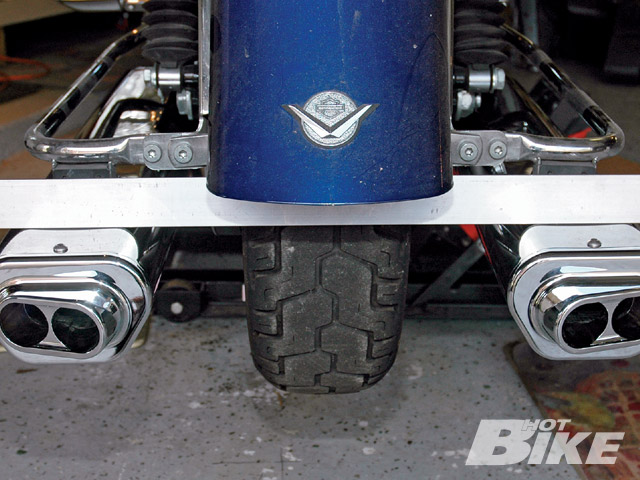

23. We used a straight edge to align the mufflers.

24. Now it’s time to install the proper ECM map for this combination of parts. After installing the TTS software we connected the PC to the ECM diagnostic port using the TTS interface and cables.

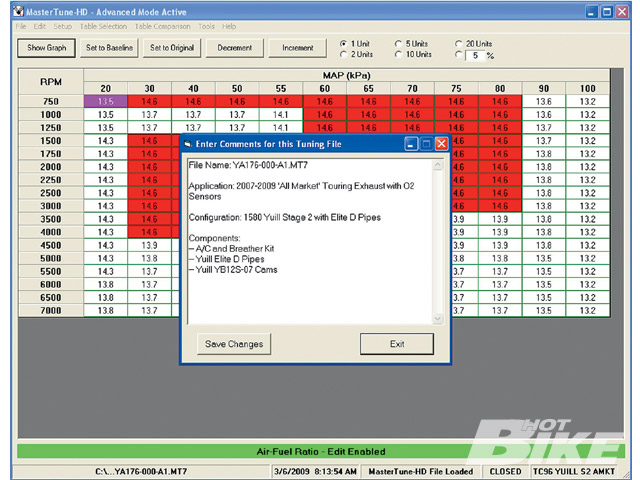

25. We opened the MasterTune-HD program then opened the calibration file. You can verify this by selecting “Edit File Comments” which should show you the year, make, model, and components for your calibration.

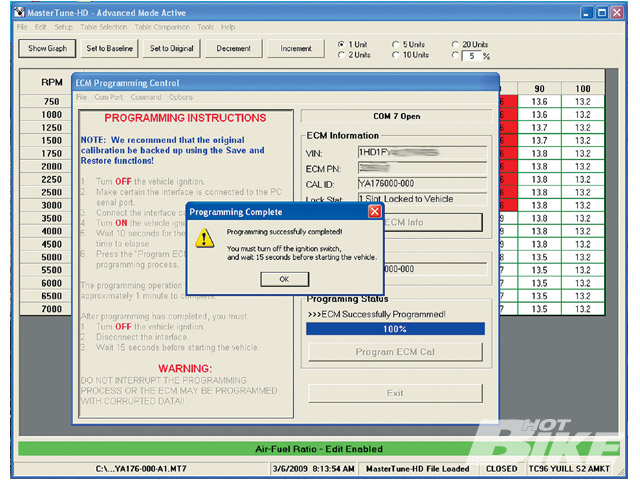

26. Next, under the “File” command we selected “Program ECM”. In the pop up box we selected the “Get ECM Info” button to confirm communication with the ECM. Finally, we selected the “Program ECM Cal” button to upload the calibration file and the installation was complete.

27. Here’s the complete Yuill Bros. Stage 2 kit installed. No complaints from the looks department. Right off the bat the bike ran fine with no hiccups and we could immediately notice the added power. Next month we’ll follow up with more info on the MasterTune program and take the bike over to The Dyno Difference to get some fine tuning and final dyno numbers.

What could a couple of retired NHRA Pro Stock drivers know about producing high-end performance products for Harley-Davidson motorcycles? A lot it seems. We installed Mark and Brad Yuill’s Stage 2 kit on our 2007 Road King Custom and we can report up front that the kit combination delivers a solid, rideable experience that exceeded our expectations.

Our Stage 2 kit came with an Elite Billet Air Cleaner – Chrome Flame (MSRP $628.95), gear driven cams and installation kit (MSRP $339.95), Elite D Exhaust Set (MSRP $1,195.95), MasterTune TTS ECM reprogrammer (MSRP $425.00), and Yuill Bros Custom Map (MSPR $200). Parts and styles for your kit will vary based on your design choices and motorcycle.

Yuill Bros claims that they provide high-end looks, improved engine cooling, a deep sound, and increased horsepower and torque in the preferred low-mid rpm riding ranges. We’ll explore those claims in two articles. Beginning this month with the basic parts installation and evaluation. Then next month we’ll finish with tuning, performance, and ride.

The kit is a complete setup of high quality, well matched parts. Just about everything we needed was included – from gaskets to clamps. We went to Lucky Devil Metal Works where Brad Latham, the former crew chief on Mancuso’s Nitro Harley Racing Team, installed the gear driven cams and we installed the high flow air cleaner and true dual exhausts at our Houston shop.

After installing all the parts we reprogrammed the ECM with the Yuill Bros. supplied MasterTune TTS base calibration map designed specifically for our model bike and Stage 2 kit. Our map is one they originally developed and refined using the H-D Race Tuner and the first one converted to Master Tune TTS. Their maps, along with a growing number of other maps, are distributed through the MasterTune Software Update Program.

Because later model Twin Cam motors run hot, the Yuill Bros. engineered specific cooling features into their air cleaner body and exhaust. A large hole in the rear of the air cleaner body directs a blast of cool air onto the rear cylinder. Then a combination of the large step-up header pipes and in-the-muffler backpressure points pull hot exhaust gas away from the heads. On our first long test ride, we used the MasterTune Data Master program to record ride data. Our bike averaged a stable 230 degrees Fahrenheit which is several degrees cooler than it had been running.

The Elite D Exhaust System looks great on the bike and produces a hearty, strong sound at idle and steady throb at speed. We measure the sound at 116 dB at half throttle. The Yuill Bros web- site has video clips of the exhaust.

Next month, after we visit our Dallas based motorcycle tuner, we’ll describe the MasterTune TTS tuning and post four performance horsepower/torque numbers: (1) stock, (2) Yuill base calibration file, (3) Yuill base after TTS VTune (a good illustration of what a “home tuner” could expect), and, (4) a custom master tune.