ProCharger Supercharger Installation on a Harley Davidson Fat Boy – TC-88

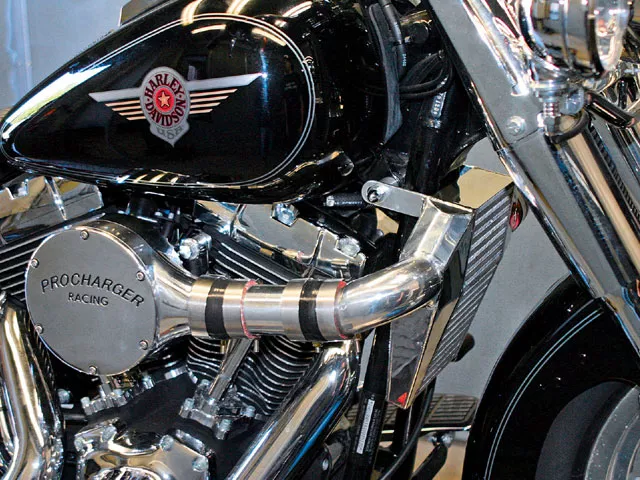

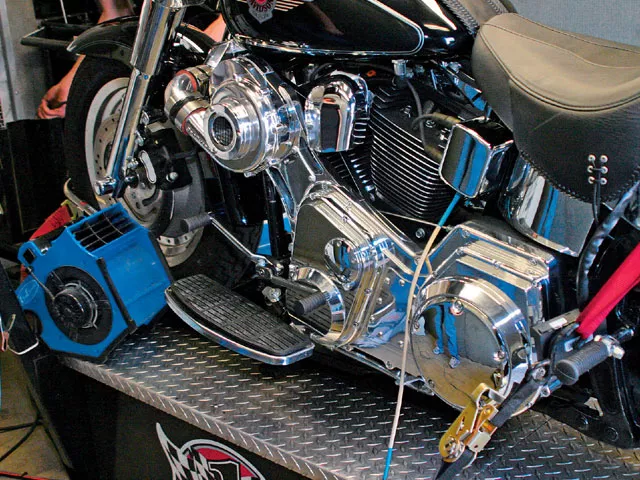

Here’s a right-side view of the completed installation.

The stock Twin-Cam outer primary cover was replaced with ProCharger’s custom CNC-machined primary.

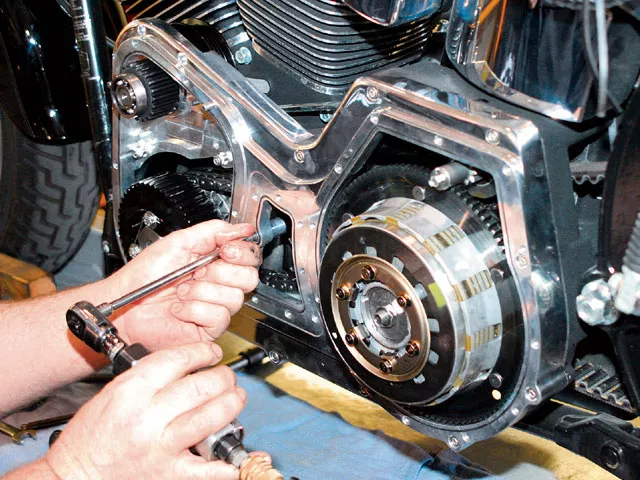

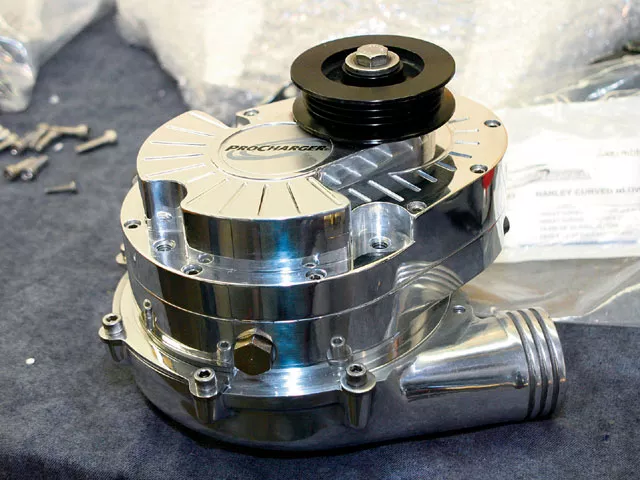

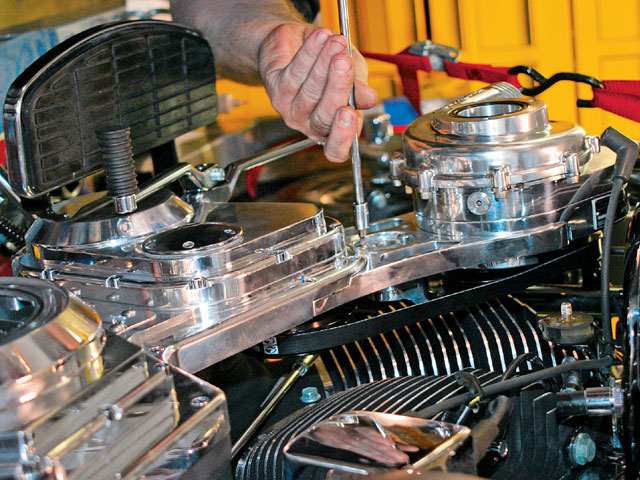

Here’s the ATI primary cover flipped upside-down and with the clutch and PTO covers installed. The four-rib belt pulley provides power from ATI’s power-takeoff assembly to the centrifugal supercharger.

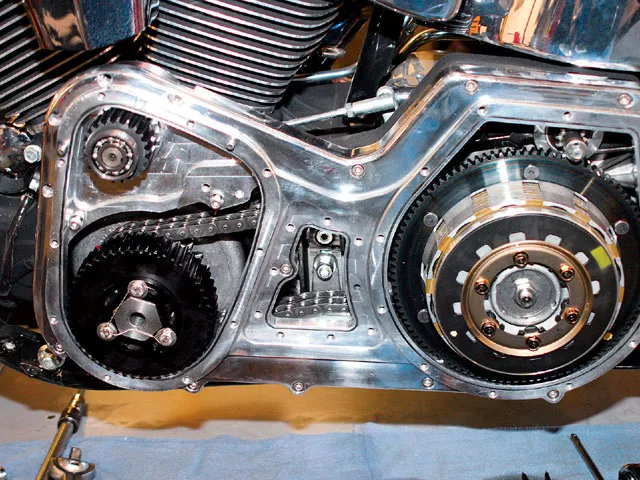

ATI’s CNC-machined primary cover includes outstanding detail and finish, along with top-quality socket-head cap screw fasteners, as well as O-ringing of the access-cover mating surfaces for a leak-tight seal.

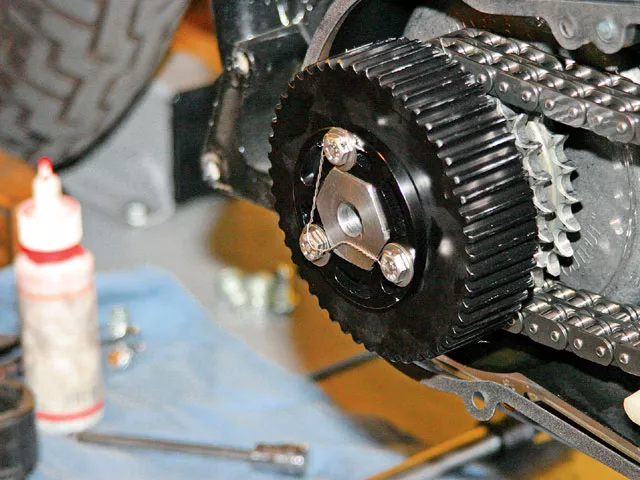

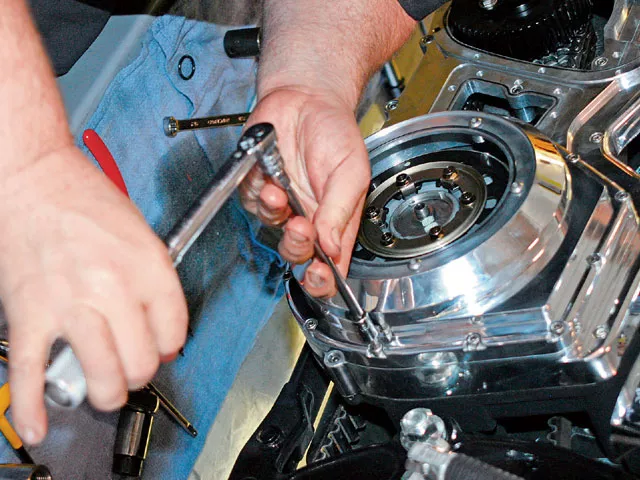

Once the stock primary cover was removed, the compensator spring cover was replaced with a compensator drive sprocket. The drive sprocket transmits power directly from the crankshaft to a 20mm Kevlar wet belt, which in turn transmits power to the PTO output shaft.

After applying a couple drops of 272 LockTite on the nut threads, the compensator drive sprocket was installed and secured with the large compensator nut. Next, the three drilled head cap screws were installed and safety-wired using safety-wire pliers.

The stock inner primary gasket surface was cleaned and a thin film of RTV black silicone was applied to the mounting surface. Next, the supplied cover gasket was installed and another thin layer of silicone sealer applied to the outer cover gasket surface. Then the PTO primary cover was installed and secured with the included socket-head cap screws.

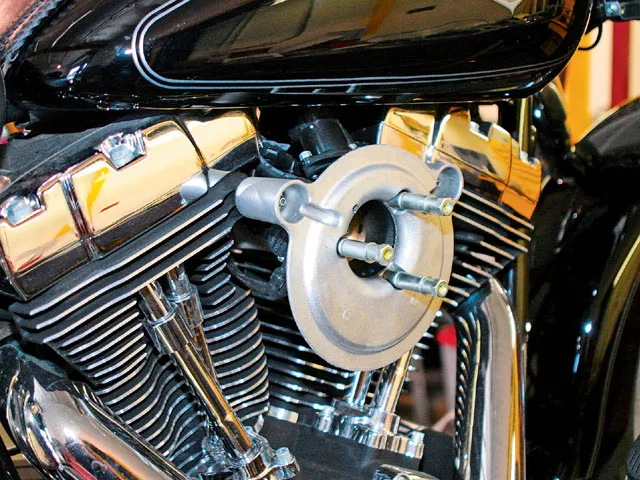

Here’s the Fat Boy drivetrain with the new ProCharger primary cover installed.

After installing the new ProCharger primary cover, the 20mm Kevlar wet belt was installed over the large drive pulley (bottom) and smaller driven cog pulley (top left). Then the eccentric tensioned assembly was installed (top right) into its loosest position and secured with the socket-head cap screw.

After the wet belt was installed, the PTO cover’s O-ring was inserted in its retaining groove, and the PTO cover was installed over the alignment dowel pins and fastened with 10 socket-head cap screws.

After installing the PTO cover, the clutch cover O-ring was installed into its retaining groove. Now the starter bushing, which is located inside the clutch cover, was aligned with the starter jackshaft, and the clutch cover was bolted down to the outer primary cover.

The primary chain inspection cover, along with its sealing O-ring, was installed after the clutch cover. With the bike standing upright, the primary chaincase was filled to the proper level with Screamin’ Eagle SAE 20W50 synthetic lubricant through the derby cover opening. Next, the O-ring and derby cover were installed and secured with five socket-head cap screws.

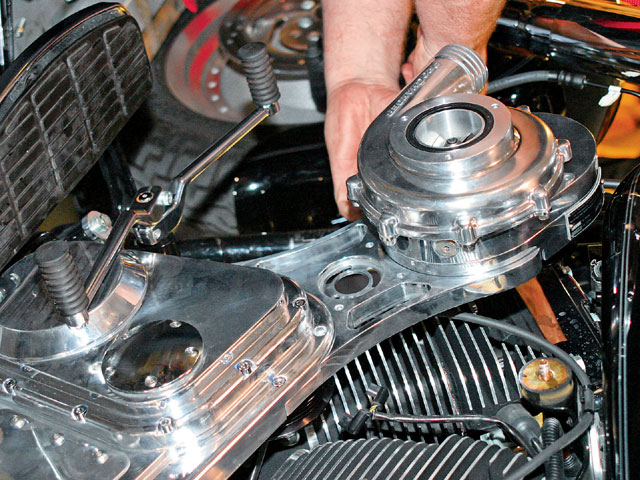

The ProCharger mounting bracket was then installed using the supplied cap screws.

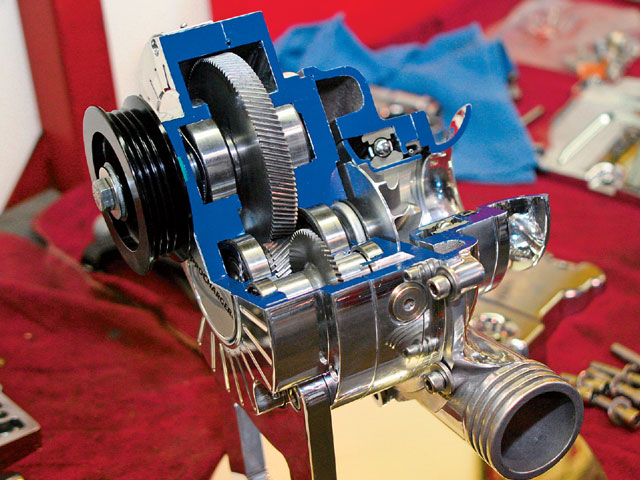

Like a turbocharger, a centrifugal supercharger uses an impeller to compress air. However, unlike a turbo, which is powered by exhaust gases, the centrifugal supercharger’s impeller is driven off the crankshaft by pulleys and two drive belts.

Here is a cutaway showing the guts of the ProCharger.

The ProCharger was set into the mounting-bracket saddle and secured with three fasteners. The air inlet faces outward from the bike’s left side, while the driven belt pulley is hidden from view behind the unit on its right side.

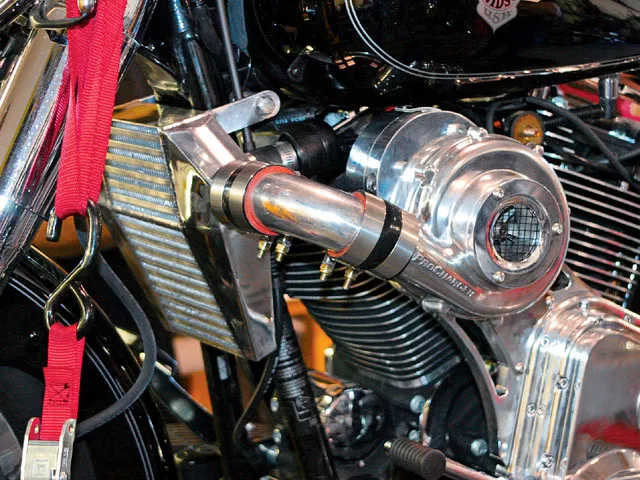

The dry four-rib belt was looped over the ProCharger’s driven pulley and the PTO cog pulley. Belt tension was adjusted with the tensioner located in the supercharger mounting bracket.

ProCharger uses a self-contained centrifugal compressor, which eliminates the need for engine oil for lubrication and cooling. Special compressor oil is included with the ProCharger system.

A Dynojet Power Commander is included with EFI ProCharger kits. The Power Commander plugs directly in line with the stock electronic control unit (ECU) and allows for fuel-injection and ignition-timing adjustments.

A new air-cleaner backing plate was mounted to the cylinder heads and throttle body.

Next, the air-cleaner element and aluminum bonnet were attached to the backing plate while the intercooler was mounted to the frame downtubes. The cooled air then flows to the discharge tube and ultimately to the air-cleaner assembly.

Here’s the left-side view of the completed installation.

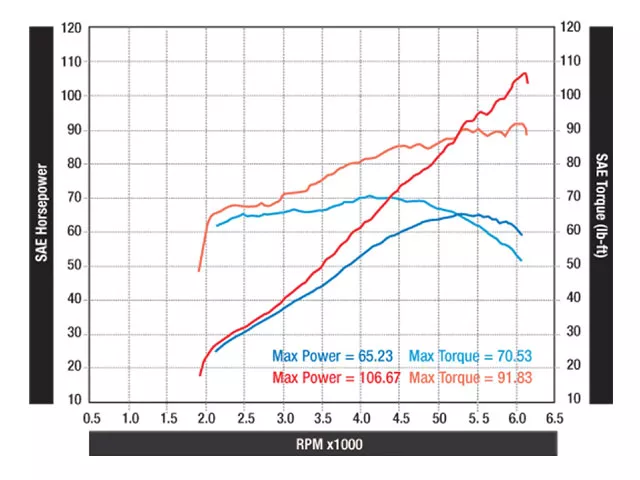

The stock TC-88 produced about 61 horsepower on the LifeStyle Cycles dyno, while the ProCharger-equipped engine developed 106.

To support the fuel flow required at the 100-plus-horsepower level, the ProCharger kit includes a high-pressure fuel-pressure regulator that replaces the stock unit. The fuel-pressure regulator is located in the gas tank.

Here’s the ProCharger-equipped Twin-Cam 88 on the Dynojet ready for its dyno tune.

There’s no big secret to making power in the V-Twin engine; just cram as much air as you can into the cylinders on the intake stroke, add the correct proportion of fuel, then efficiently burn the air/fuel mixture on the power stroke. However, the way you go about stuffing the cylinders is a matter of choice. Some power junkies follow the “no replacement for displacement” route. And that’s cool. But others lean toward power-adders.

LifeStyle Cycles believes in both philosophies for making big power numbers. LifeStyle’s crew is well-versed in the intricacies of hopping up V-Twin motors and has a well-equipped shop to get the job done. As such, Junior, LifeStyle’s owner, thought it was about time to build a new project bike with a supercharger power-adder as the first phase of an evolutionary power-development project. Located in Anaheim, CA, LifeStyle Cycles invited the staff of HOT BIKE magazine to follow along as the crew there installed an Accessible Technologies Inc. (ATI) ProCharger supercharger on a bone-stock Twin-Cam 88 EFI Fat Boy.

Unlike a naturally aspirated engine, which relies on atmospheric pressure to fill the cylinders, a supercharger (aka a blower or power-adder) is a crank-driven compressor that forces huge amounts of air into the engine’s cylinders, increasing engine power dramatically. Currently, there are two designs of superchargers available for the V-Twin engine: roots and centrifugal. Where a roots-style blower uses spinning rotors to develop pressure or boost, a centrifugal blower uses a fan-like impeller rotating at high speed to develop boost. Although a centrifugal blower may look similar to a turbocharger, it’s different. Turbochargers are powered by hot exhaust gases, where superchargers are crankshaft-driven. Since it’s crank-driven, there is no power lag with a supercharger, and boost starts instantly right off idle and builds as rpm increase.

In case you haven’t already heard of ATI, the company is well-known in the automotive industry for offering reliable supercharger applications for increased power. As such, it has applied proven supercharger technology from the automotive world to the V-Twin engine, including intercooling for optimized power. ATI chose a centrifugal-style supercharger for its ProCharger kit because a centrifugal design is compact and can be spun at higher rpm for high boost and efficiency, reducing the temperature rise of the compressed intake charge and parasitic power losses. ATI then took supercharging the V-Twin engine one step further by adding a neat intercooler to its ProCharger package. The intercooler is an air-to-air heat exchanger that reduces the elevated intake charge temperatures exiting the supercharger. These lower temperatures increase air density, which is critical for increasing power at high rpm when the charge air is highly compressed and substantially heated.

ATI’s ProCharger system offers excellent craftsmanship and comes as a complete bolt-on kit, including all required parts and fasteners. Major components include the compact supercharger, stylish intercooler, drive assembly, and ducting. All parts are symmetrically positioned on the motorcycle for clean aesthetics and excellent balance. The crew at LifeStyle Cycles took less than five hours for the complete installation on the EFI-equipped Fat Boy, not including the time on the dyno. ATI offers both carbureted and EFI ProCharger kits and includes a Power Commander unit for precise fuel and ignition tuning on EFI-model bikes. An added benefit of the ProCharger is that it can be easily removed and installed on a different bike. (Check out the included dyno chart to see how ATI’s ProCharger kit achieved about 106 horsepower [a 74-percent increase over stock] with 10 pounds of boost on a bone-stock TC-88 Twin-Cam engine.)