ProCharger Intercooled Supercharger – Supercharged!

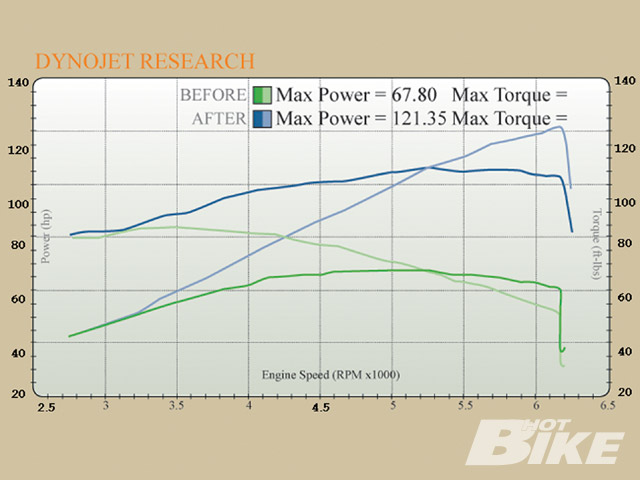

1. Blown away! The Rocker boasts an extra 10psi of boost. That means an extra 53 hp and nearly 22 lb-ft torque!

2. Here’s what you get in the kit: the supercharger assembly, which includes a complete air-to-air intercooler system, outer primary cover, air cleaner assembly, supercharger bracket, power take-off assembly (PTO), belt tensioner, surge/bypass valve, computer programming software, belts, hoses, and everything else needed for the installation.

3. For this install, a Bassani 2-into-1 Road Rage Exhaust system for Rocker models was used. This bike was also fitted with an AIM Corp Variable Pressure Clutch assembly (Starting at $245) because it is a simple bolt-in piece that increases the clamping force as the rpm increases. This part offers easy clutch pull, fits under the stock derby cover and allows the use of all stock components. A Zipper’s Thundermax EFI unit with AutoTune ($899.95) was also used for this install and a two-bar map sensor ($175) was added.

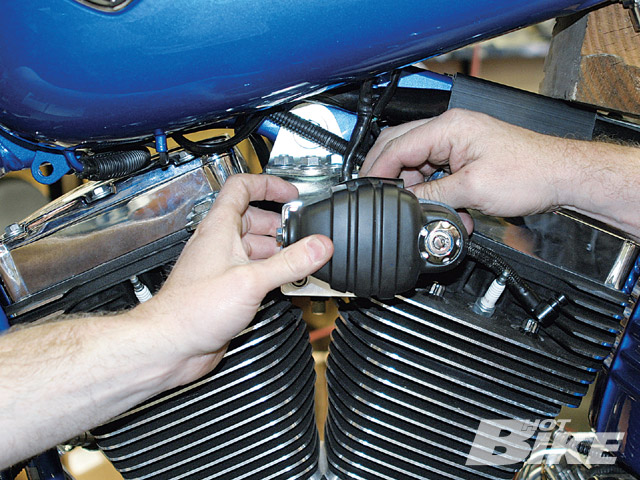

4. After removing the outer primary cover and the stock air cleaner assembly in order to fit the ProCharger components, Walt propped up the tank, removed the fuel line, and then the stock fuel rail and stock injectors located on the throttle body. Shown is the new fuel rail and new injectors installed (not shown in pic #2), ready to be mounted to the throttle body.

5. Provided in the kit is a coil relocation bracket for Rocker and Rocker C models to ensure proper clearance between the Procharger system and the coil. Ed installed the bracket, which rotated the coil 90 degrees clockwise.

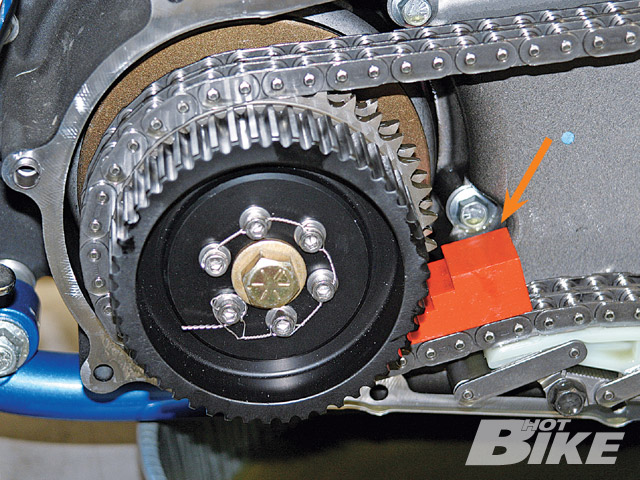

6. Back down to the primary, Ed removed the stock compensator bolt first and installed the PTO assembly, which bolted right onto the compensating sprocket. The PTO is driven by the crankshaft and transmits power to the PTO output shaft at a 2.3:1 ratio to the crankshaft via the 21mm Kevlar wet belt. You’ll need the primary locking tool shown here to complete this step (arrow). Red thread locker was used on the new 9/16-12×4.5-inch bolt, which was tightened to factory spec.

7. ProCharger’s new primary cover comes assembled but needs to be disassembled for installation. Ed started by removing the clutch cover

8. …then he took the PTO cover off. Ed needed to temporarily remove the eccentric tensioner assembly, which he’s doing here, in order to install the cog belt around the PTO assembly and the cog driven assembly (left of eccentric tensioner assembly). The tensioner will be re-installed and set to achieve maximum belt life.

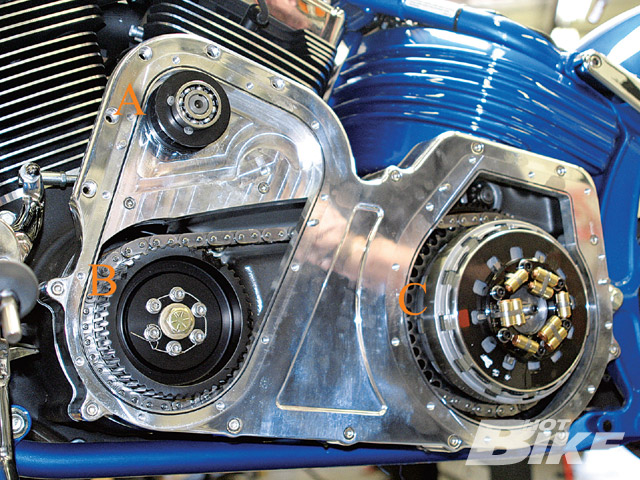

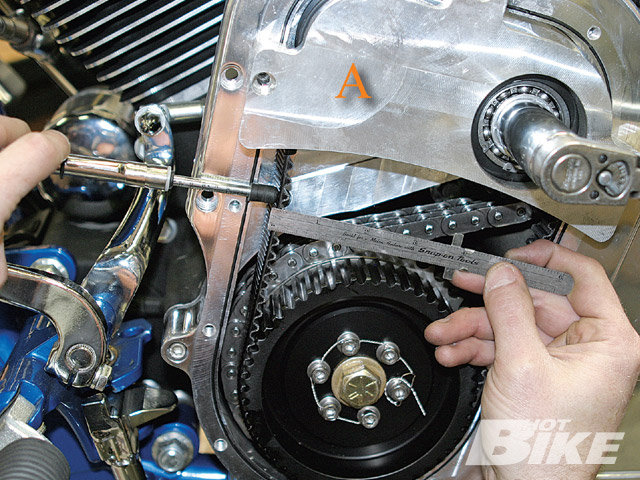

9. Here’s a shot of how the entire primary assembly looked before the cog belt was installed. Shown is the driven cog pulley (A). Underneath is the PTO assembly (B). And let’s not forget the AIM Corp Variable Pressure Clutch assembly (C) that was installed to handle the big power increases from the supercharger.

10. The cog belt was installed, followed by the reassembly of the eccentric tensioner unit. The eccentric tensioner was then set to achieve maximum cog belt life (approximately 10,000 miles). After that, the motor was turned over in order for the cog belt to track the pulleys.

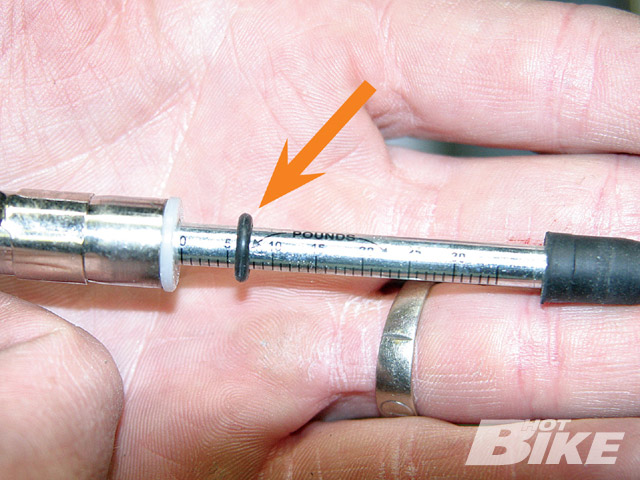

11. To adjust the tension of the cog belt, Walt slid the round band on the tension tester (arrow) between 6.0 and 6.5 pounds force because this tension helps achieve the maximum life of the cog belt.

12. Bolted over the eccentric tensioner assembly and the driven cog pulley was a tensioning jig (A) provided in the kit. This jig is removed once the desired belt tension is achieved. In this case we were looking to achieve between 3/32 to 1/4-inch of deflection using the edge of the belt as a reference point. When the proper deflection was achieved, the tension tester read between 6.0 and 6.5 pounds force. Ed tightened the tensioner bolt to 18-22 lb-ft after Walt took some final measurements.

13. Once the belt tension was set, the PTO cover was re-installed and then the clutch cover was re-installed after 1.5 quarts of primary fluid had been added.

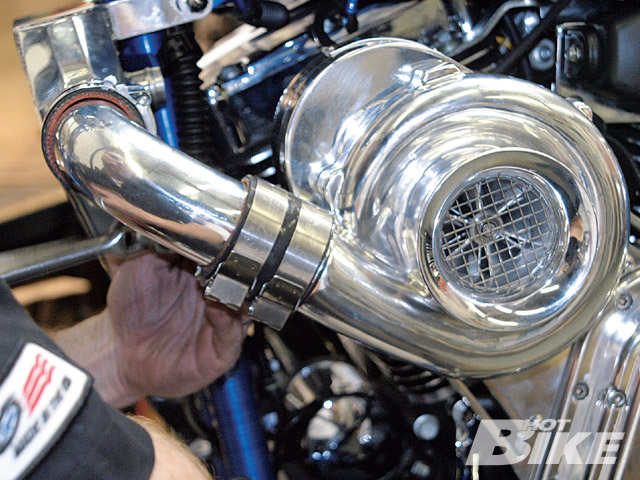

14. Walt moved on to the supercharger assembly and poured the provided 2.5 ounces of oil in the supercharger assembly since this is a self-contained oiling unit with no oil lines. The unit is CNC machined from billet aluminum and features precision bearings and helical gears. There are four determining factors that affect the unit’s impeller speed: engine rpm, PTO step up ratio (2.3:1), PTO driving pulley to B1 driven pulley ratio, and the internal 5.0:1 internal gear ratio on the unit itself.

15. The ProCharger was attached to the supercharger bracket mounting saddle with the provided hardware and thread locker.

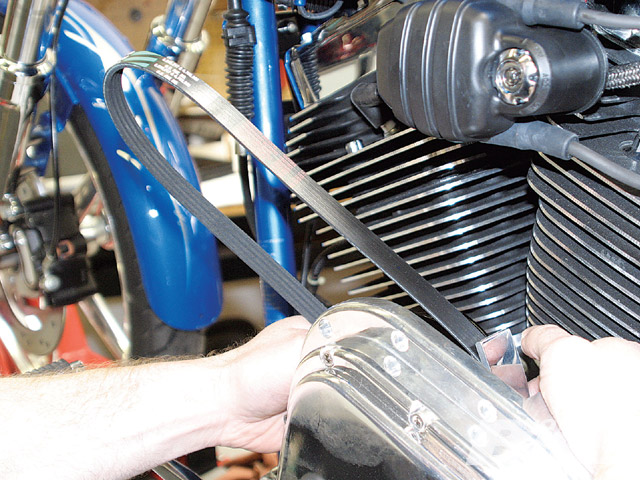

16. The serpentine style belt was attached to the inside of the primary and then to the pulleys on the back of the supercharger assembly.

17. The supercharger assembly was then attached to the PTO bracket saddle on the back of the primary cover and then the serpentine style belt was adjusted to the proper tension. The serpentine belt tension was set via a tensioning pulley and jack screw attached to the supercharger bracket. As the screw was turned the pulley increased pressure on the belt and needed to be tightened until the belt was unable to be twisted past 90 degrees in order to achieve maximum belt grip on the pulleys. If the belt slips too much, the proper amount of boost may not be achieved.

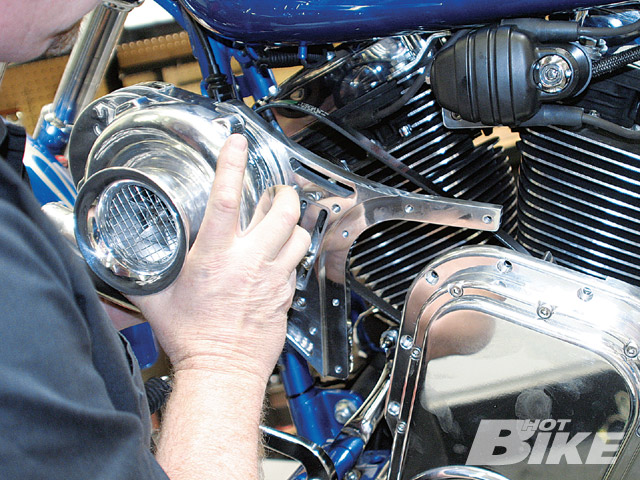

18. Walt prepped the air cleaner bonnet assembly to mount it in place. The unit is made from high-grade billet aluminum and bolts right onto the stock throttle body.

19. The backing plate was mounted to the throttle body and a K&N; air filter was installed followed by the air cleaner cover.

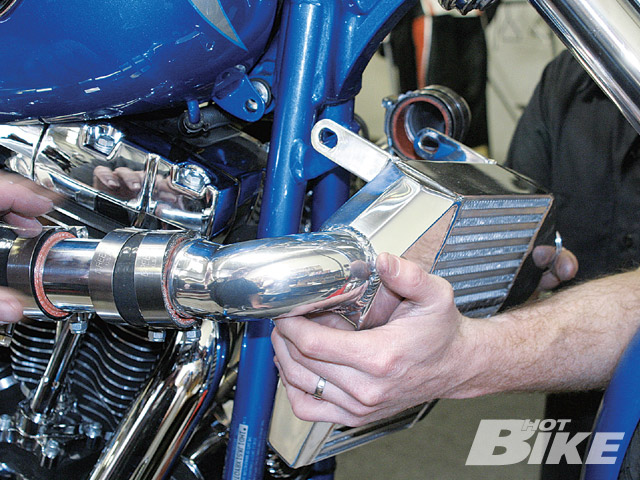

20. Next, the intake assembly was attached to the intercooler via the silicone rubber hoses and clamps and the installation neared completion.

21. To make room for the intercooler, Walt relocated the horn with the provided bracket to sit a bit lower between the frame’s downtubes above the regulator.

22. The intercooler was mounted next. It was bolted to the gas tank mounts and fits underneath the neck gusset.

23. Walt and Ed snugged up all of the hose clamps from the air cleaner bonnet, to the intercooler, to the supercharger and then the surge valve was hooked up.

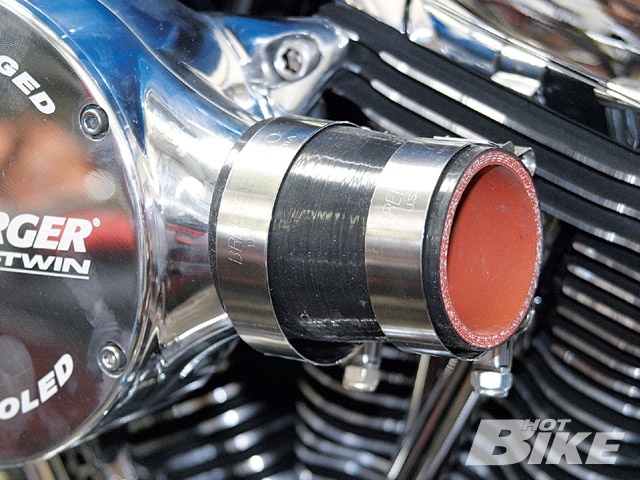

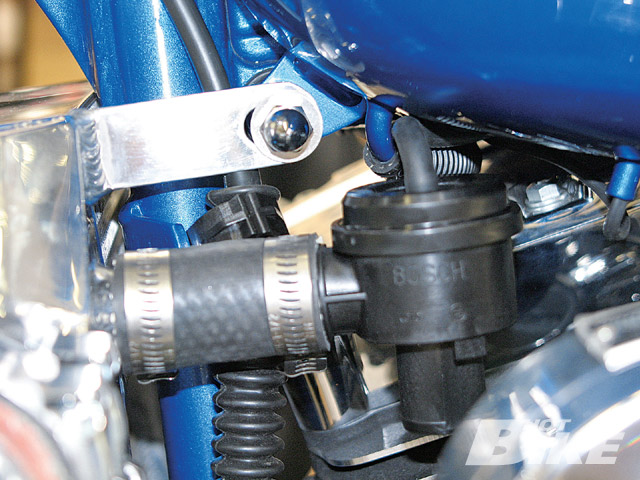

24. Here’s a shot of the surge valve after it was installed. It is operated by vacuum or boost, and allows boost to be bypassed from the engine during normal riding conditions (idle, cruising) so that the bike delivers normal cruising feel, fuel economy and drivability. The surge valve is normally open. Once the engine senses load however and the engine goes from a normal vacuum situation to boost, the valve instantly closes and allows the boost into the throttle body. Upon deceleration, the valve opens again so that excess boost isn’t backed up in the engine.

24. Here’s a shot of the surge valve after it was installed. It is operated by vacuum or boost, and allows boost to be bypassed from the engine during normal riding conditions (idle, cruising) so that the bike delivers normal cruising feel, fuel economy and drivability. The surge valve is normally open. Once the engine senses load however and the engine goes from a normal vacuum situation to boost, the valve instantly closes and allows the boost into the throttle body. Upon deceleration, the valve opens again so that excess boost isn’t backed up in the engine.

26. Here is the new supercharged Rocker C ready to tear up any street it rolls down.

27. And this is how the ProCharger system faired on the dyno. The baseline run produced 67.80 hp and 83.86 lb-ft of torque. After the supercharger was installed, a whopping 121.35 hp and 105.85 lb-ft of torque were achieved, which is a gain of 53.55 hp and 21.99 lb-ft or torque. No wonder this setup won Performance Product of the Year at the V-Twin Expo. It’s the real deal!

What if we told you that you could add 50-plus ponies in just four hours?! With the new ProCharger Intercooled Centrifugal Supercharger for ’07-09 Softail models ($5,195) it can be done and we have dyno proof!

There are a few ways to achieve substantial horsepower and torque gains, but without doing any major engine modifications, a power adder like this is the only way you’re going to see big numbers from a stock 96ci engine. The ProCharger is a bolt-on kit that does not require any engine modifications. And with a product that won Performance Product of the Year in 2008 at the V-Twin Expo, we had to see if the system measured up.

Walt Sipp, V-twin product manager at ProCharger came to us with a ’08 Rocker that was begging to get blown. We went to Huntington Beach Hogs and Choppers in Huntington Beach, California, to do the install. After putting the ProCharger on the dyno we almost soiled our trousers when we saw the numbers!

Supercharger And intercooler Basics

In Volume 41 Number 3 of HOT BIKE, William Denish gave you the skinny on how superchargers and intercoolers work. Here’s a quick recap. This ProCharger model is an intercooled centrifugal belt-driven supercharger that is mechanically driven off of the crankshaft to pressurize the entire induction tract above 14.7 psi (normal atmospheric pressure). So essentially it increases the pressure differential between the manifold and cylinder to create what is called charged air (greater mass of air than atmospheric pressure alone that flows into the cylinder). Since the supercharger is driven off of the crankshaft, boost is immediate and simultaneously increases as rpm increases. Boost is pressure above 14.7psi. So for example if you add 10psi of boost to the engine’s induction system, the engine sees the sum of both for a total of 24.7psi.

An intercooler works to bring charged air (heated air) to a lower temperature when it enters the throttle body/carburetor. Cooler air is denser, contains more oxygen, and requires a lower level of fuel octane, which reduces the risk for potential detonation. Detonation is bad for your engine’s components. Basically, as your blower shoots air into the engine it is temporarily suspended in the intercooler assembly, passing through a series of passages, cooling the temperature before the air then flows into the throttle body and into the engine.