Performance Machine Contour Hand Controls

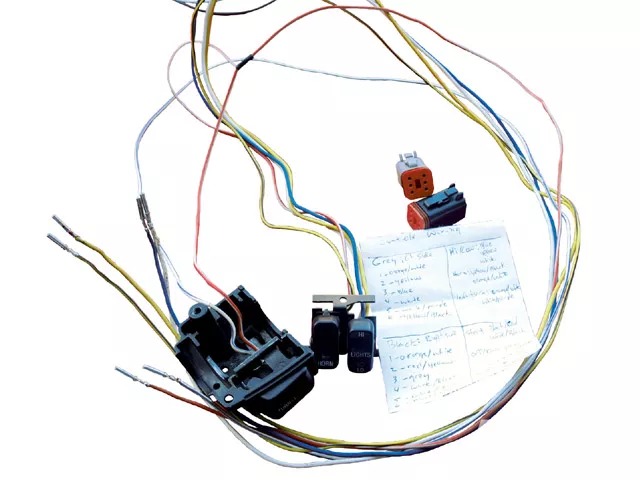

1. Our chrome Contour setup ($1,189.75) came with; starting on the left side: a spacer to fit between the grip and switch housing, left switch housing, and clutch lever. On the right side is the throttle housing, right side switch assembly, and front brake lever with master cylinder. The switch housings come with 36-inch wire leads and PM also includes a very comprehensive instruction sheet as well as a color-coded wiring chart.

2. This project bike had been in a mid-teardown state for quite some time. The stock hand controls and handlebars were already off the bike when we started. Several months back upon disassembly, we had made sure to write down the position of all the stock wiring leads into the connectors for both the left and right side and kept the chart in a safe place-just in case.

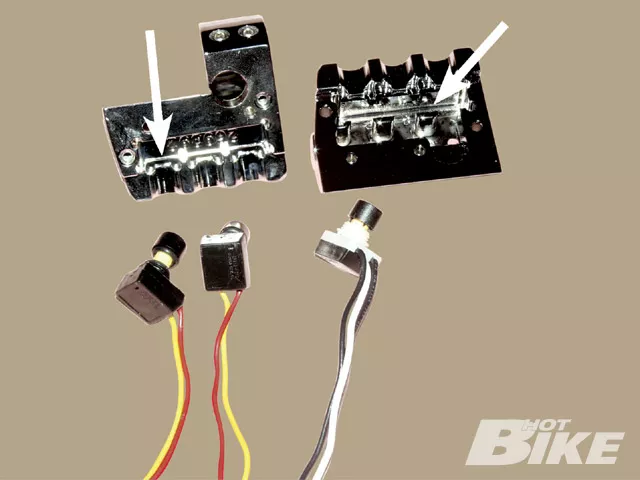

3. We disassembled the PM switch housings so we could use the wiring hole in the top half of the switch housing to indicate where to drill to run the wires internally. There’s a channel on the inside of the housings to help keep the wires from getting pinched once installed (arrows).

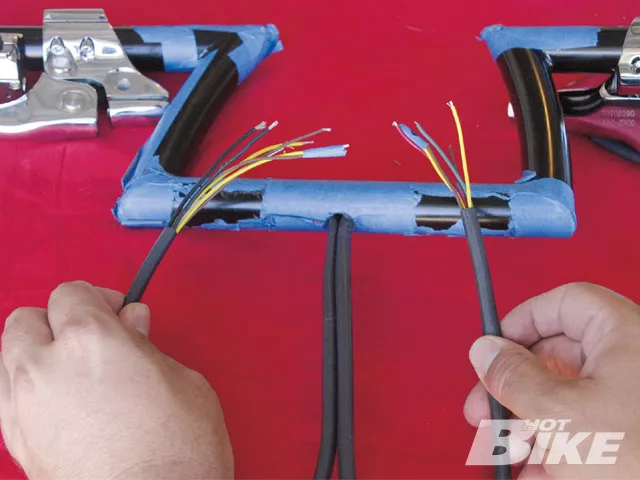

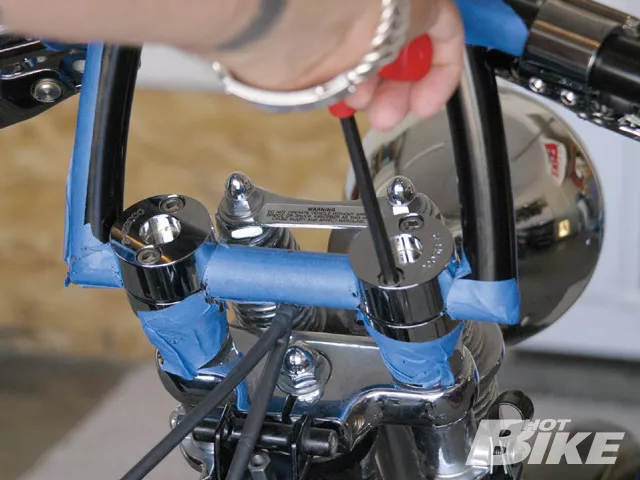

4. To get started, we fit the controls onto the bars and set them in a comfortable riding position so that we could mark where to drill. Once we were set on a position, we marked the location with a pen. To help protect the black finish on the bars from getting too scuffed and scratched we wrapped them with some blue painter’s tape.

5. The Biltwell bars weren’t center drilled for internal wiring, so we measured out the center of the bars while they were still sitting in the risers. Then we removed the bars and hand controls and used a punch to detent the bars and help keep the drill tip in place.

6. Next, we used a stepped drill bit to open the center hole to 1/2 inch so that both the left and right switch leads would easily fit through.

7. On the bar ends we drilled smaller 5/16 inch holes for the left and right side switch wire leads. Once the holes were drilled we made sure to de-burr the holes and file down the sharp edges so they wouldn’t cut into the wires

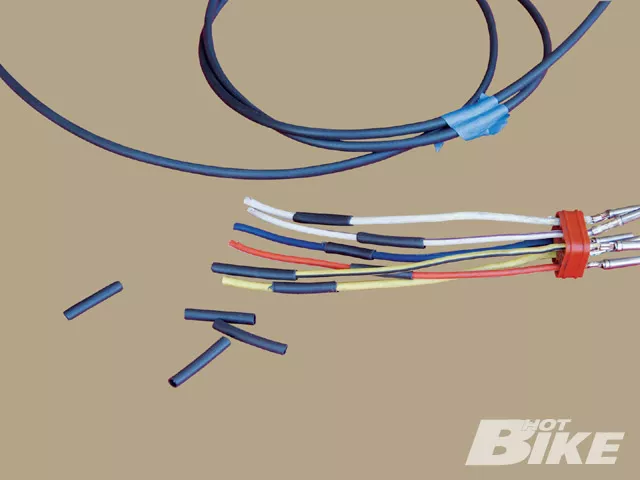

8. Both the left and right side wiring leads have two sets of brown and yellow wires. One set of brown and yellow goes to the blinker button on each side. On the right side the remaining set goes to the start button, while on the left side the remaining set goes to the horn.

9. Here are the PM wires for the right side. The directions instructed us to wrap each set of the brown and yellow blinker wires with tape so that we could easily identify the wires once they were routed through the bars.

10. Next, we needed to create a guide to pull each set of wires from the holes at the controls to the hole at the center of the bars. There are plenty of ways to do this; such as sucking a piece of string through the bars with a vacuum cleaner or fishing some lightweight wire through the bars. We found with the tight bends in these bars that a piece of string with a nut tied to the end of it worked just fine.

11. Pulling the wires through the sharp bends on the mini z-bars turned out to be quite a chore. We secured the wire leads to the string with plenty of electrical tape, then lubricated the inside of the bars the best we could to help the wires slide through easier.

12. It took a lot of patience and pushing/pulling from different angles but we were finally able to get each set of wires routed down through the center hole.

13. Next, we measured out the stock wiring leads from the stock connectors to the PM wiring leads. Then we cut the stock wires (right) to an appropriate length for our application.

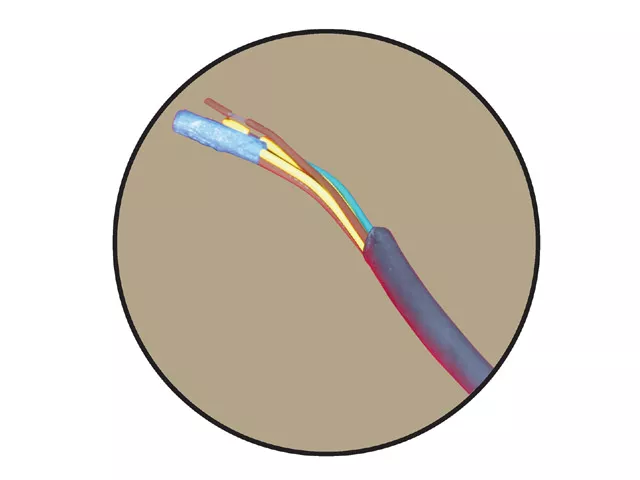

14. Next, we were ready to begin soldering the stock wires with the stock terminal ends to the PM switch wires. Before soldering we made sure to slide small strips of shrink tube over each wire.

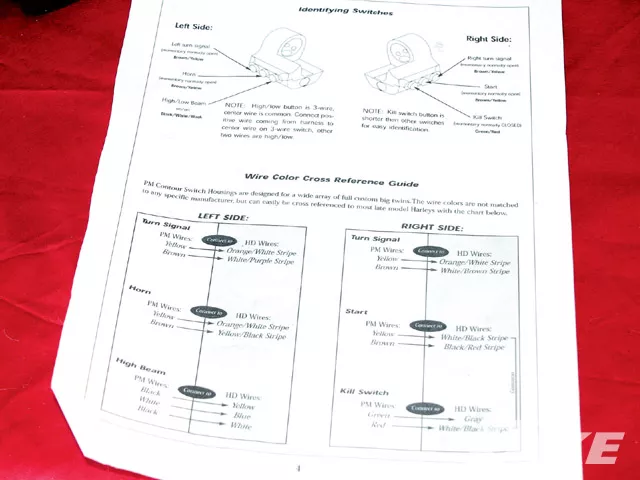

15. Here is a shot of the PM wiring diagram instructions. According to PM’s instructions the switch housings are designed for a wide array of full custom big twins. The PM wire colors are not matched to any specific manufacturer, but can be easily cross-referenced to most late-model Harleys with the provided color chart. If you lose the diagram, you can download the entire instructions off the PM website.

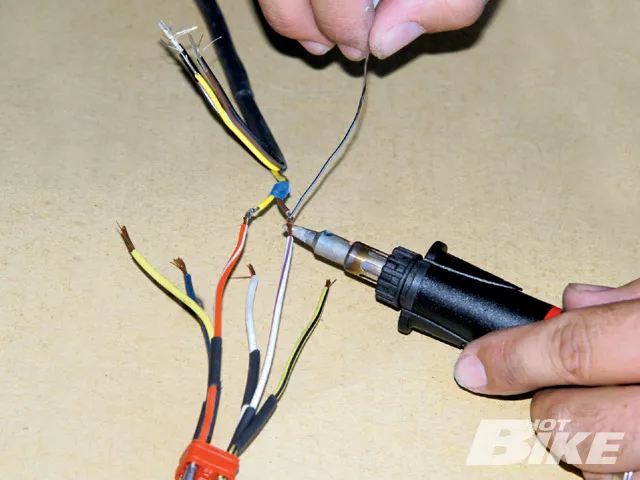

16. We picked up this portable butane soldering tool kit from Sears. It has various attachments so you can use it as a soldering iron as well as a heat gun for shrink tube.

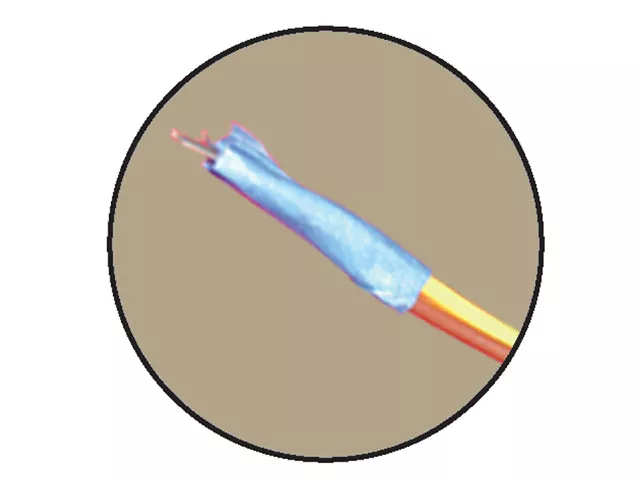

17. Once we had the wires stripped we began soldering. We heated up the wire joints first, and then applied the solder to the wire. Once the solder covered the connections, we removed the heat source and allowed it to harden. A long piece of shrink tube was slipped over all the wires on each side. This would help further protect the wires and provide a cleaner look.

18. Once we had all the connections wired and sealed we mounted the bars back onto the bike. The Joker Machine Springer risers feature a hidden mounting setup. There are two top pieces. The first piece is the actual top clamp to secure the bars (seen here), and the other is a cap that fits over the top clamp to hide the Allen bolts.

19. Here you can see how we routed the left and right side wiring leads out the bottom of the bars and down the backbone. You can also see how the top cover on the riser provides an uncluttered finish.

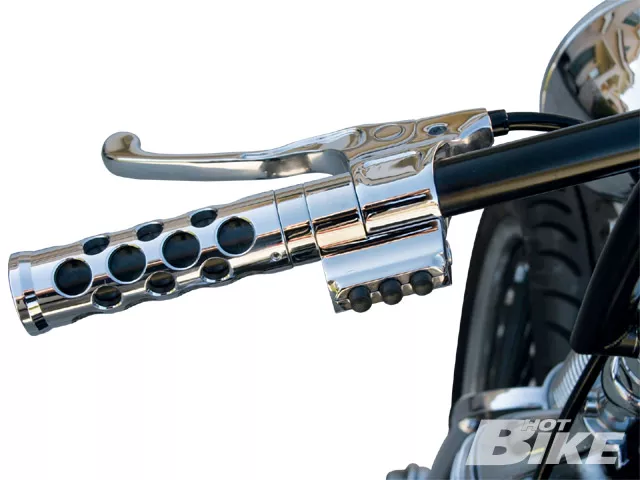

20. We used a set of Battistini grips with speed holes to help tie the black and chrome together even more. The Contour clutch lever has a nice slim design and is long enough to make pulling in a stiff clutch easy. The buttons are small enough that they don’t take away from the sleek lines of the control assemblies, but are still easy to activate. Starting from the left: left turn, horn, high/low beam.

21. On the right side you get a good look at the streamlined one-piece master cylinder assembly. The brake lever can be easily adjusted in towards the bar or out away from the bar to give you a longer or shorter pull. Starting on the far right the switches are: right turn, start, and kill. The kill switch button is slightly shorter than the other two for easy identification.

22. The aggressive look of the Biltwell bars combined with the sleek PM controls really set the tone for the rest of the bike.

After being neglected for far too long, we decided it was time to get back to working on one of our project bikes, a ’96 Softail Springer. Recently we picked up a set of Biltwell Inc. Keystone bars and some new Springer style risers from Joker Machine. The 5-inch tall z-style bars combined with the 2-inch risers gave the bike a sleeker and meaner look, but when we installed the stock hand controls, the aggressive look we were heading towards was pretty much lost. The stock housings were too bulky and the wiring leads running on the outside of the bars added unwanted clutter to the front of bike. So we sought out to find a set of hand controls that would better accentuate the look we were after, and run the wiring inside the handlebars for a cleaner look.

We found what we were looking for with a set of Performance Machine (PM) Contour Hand Controls. The controls are CNC machined from billet aluminum and feature streamlined master cylinders with hard anodized bores to eliminate wear, and the switch housings have high-quality mini buttons for that less-is-more look and feel. PM offers the controls in polished, chrome, and black anodize, and a new contrast cut finish to match the rest of its contrast cut line. The switches are available in either single button or three button housings. The three-button setup is for direct stock replacement with right turn, start and kill on the throttle side and left turn, horn and high/low beam on the clutch side. The single button setup would be for more custom applications if you were going to just run a starter and high beam for example. The controls are also offered with 9/16 master cylinders for single disc or 11/16 for dual disc applications, and a hydraulic clutch assembly is also available.