Ness-Essary Ruber Mount

Everything has to have a starting point — in this case it is the Y2K 250 frame with 5 inches of stretch and 38 degrees of rake.

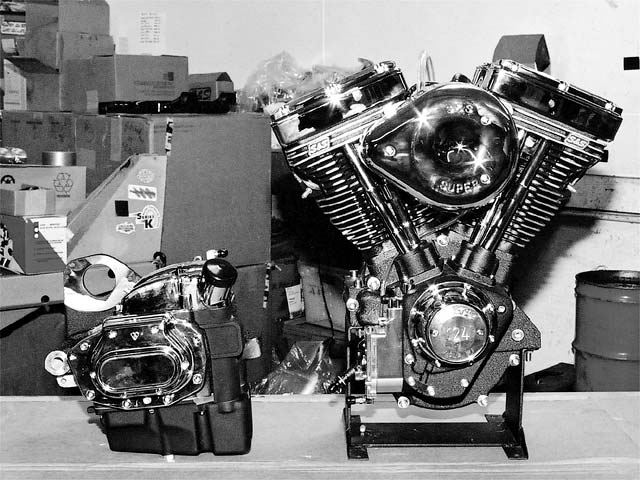

At the heart of your new bike will be an S&S; 124ci monster and a Ness-Tech five-speed transmission.

Assembly starts by connecting the transmission and motor together, making way for the inner primary.

A 1-inch primary spacer is used on the motor. This requires you to use two gaskets that should be prepped with Hylomar.

The motor spacer is slid into place…

…followed by the transmission spacers.

Now the inner primary is installed, following the steps in a Dyna service manual.

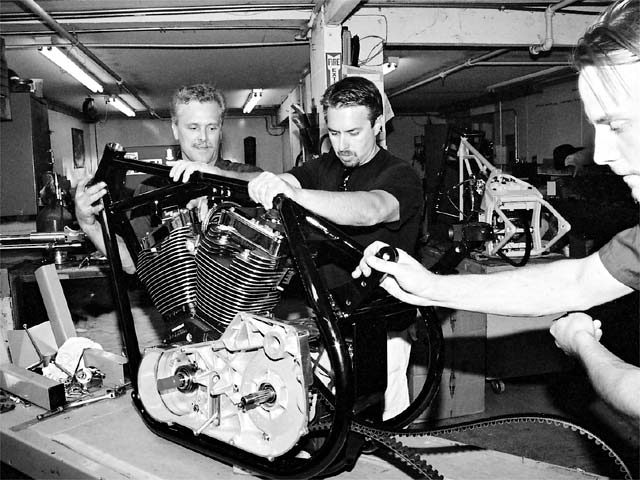

It’s time for some fun. Tony and Dustin have installed the Dyna-style motor mounts on the motor and transmission while they still lay on their side. The Y2K frame is laid around the powertrain and bolted together.

Cory Ness stops by just in time to help lift the assembly.

Next on the list is to press in the swing arm bearings, connect it to the frame, and then install the billet struts.

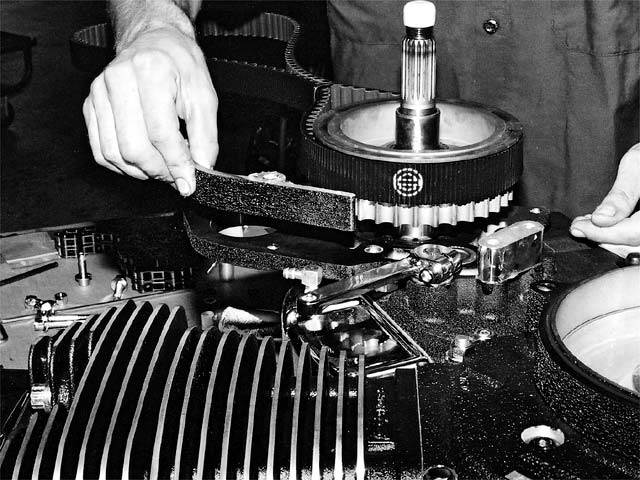

After installing the clutch and primary chain, Tony sets the proper torque…

…and Dustin records the settings.

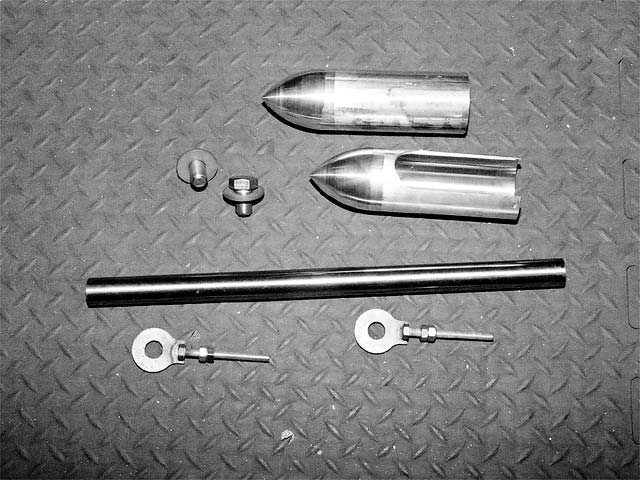

The billet end covers for the swing arm hide the axle and adjusters.

A close-up look at the adjusters shows just how slick this design is.

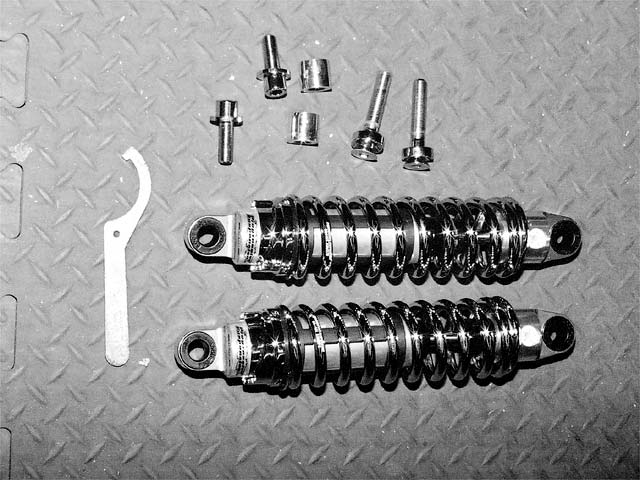

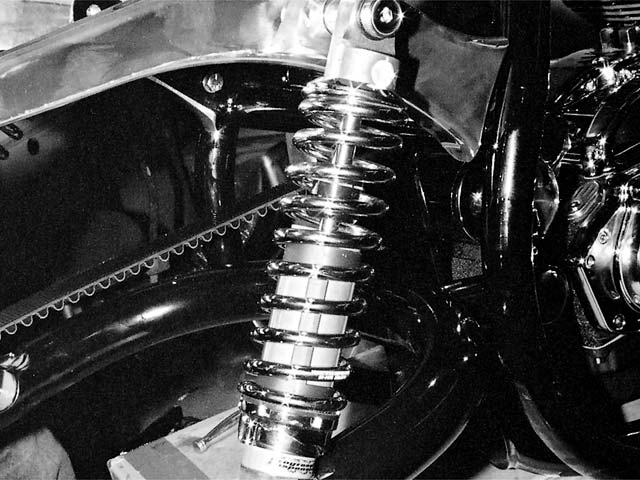

Each Y2K kit comes with 11-inch Progressive Suspension shocks built just for the chassis, all the necessary installation hardware, and pre-sized spacers.

The Progressives and the billet struts look perfect together.

Dustin installs bearing races in the 38 degree neck…

…while Tony unpacks the Ness chrome billet trees.

Tony has a different approach to greasing steering-neck bearings. Rather than put them in a press and inject them full of grease, he prefers to use a liberal outer coating on the bearing. His reasoning is simple: When you pack the bearing full and then tighten the neck, the fall-away tension is perfect. A few hundred miles down the road, the grease works out from between the bearing rows and the fall-away gets looser, necessitating another adjustment. By using enough grease to ensure proper lubrication, he saves additional work after a week or two of riding.

The trees are positioned with the bearings in place…

… and the big 41mm tubes are slid into place.

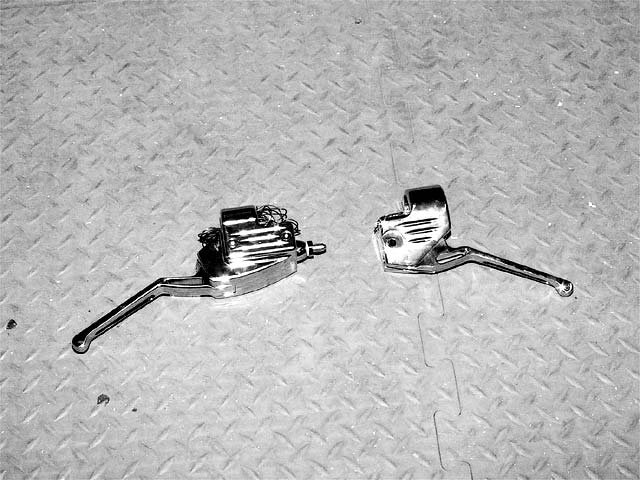

Moving to the top, Ness hand controls are unpacked…

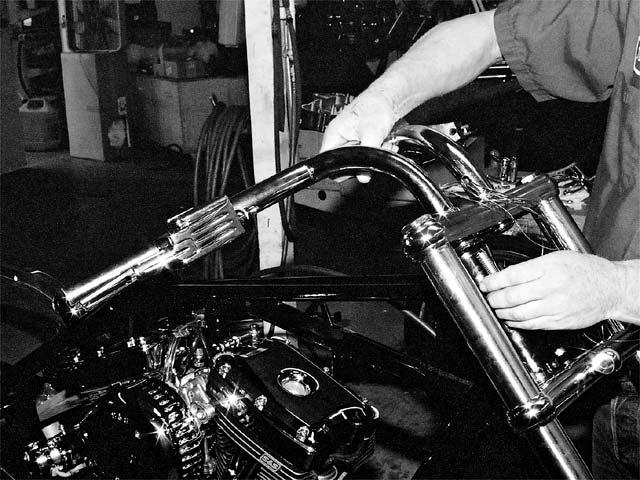

…the wires are run internally and then the pullback Ness bars are installed.

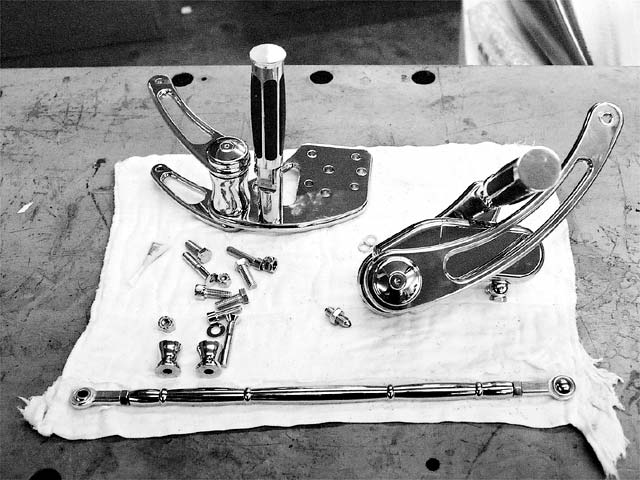

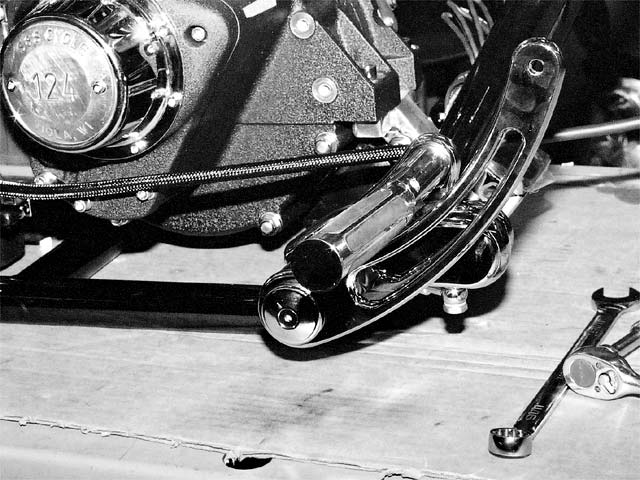

Your new custom will have chrome billet Ness forward controls.

A very clean feature on the Ness controls is the basically hidden master cylinder that makes for a slender, sleek look.

Well, here is where we will leave you this month. A Y2K frame, a 124ci S&S; motor, and some suspension. Next month, we’ll drop in some wheels and sheetmetal. While you wait, why don’t you drop that entry card in the mail?

Once in a while, things really surprise us because they actually go smoothly. In the case of the Ness Y2K design and our magazine, things have been like silk since January of 2000 when we premiered the new chassis on our cover.

While we knew that first Y2K was a sleek design and had rubber-mount comfort, what we didn’t know was that it was going to be offered in the Ness catalog the next year. We were thrilled to hear it, because the story on that bike brought us an unbelievable number of calls and letters asking for more detail.

So when we approached the Ness team about building us a sweepstakes bike, we were secretly hoping it would be built using the Y2K. The frame is offered in two versions: a 2-inch stretch with 35 degrees of rake or 5 inches with 38 degrees. The tubes are 1-3/8-inch diameter and the beefy swing arm is made from 2-inch tubing; it has billet covers to hide the axle.

Another reason we dig this chassis so much is the low seat height. Even though it’s rubber-mounted, the base of the seat is just 17 inches from the bottom of the frame! So you can have vibration-free performance and boulevard coolness, all from the same frame. Oh, there are many more reasons you’ll want to win this bike, by the way.

How does power from a 124ci S&S; motor sound? Does a complete Ness sheetmetal package interest you? What about a set of Ness billet wheels, Avon tires (a 250 rear), and Ness calipers? And the final, incredibly sweet part of winning this Ness custom bike — it will grace the cover of our magazine when it’s done. That means, if you win, you will not only own a custom-built Ness bike, but you will also own a HOT BIKE cover machine!