Motorcycle Wheel Building 101

When it comes to anything to do with wheels, there’s no better experts than Wheel Works in Garden Grove, California. They have been our go-to guys for years and are the ideal people to show us how a wire wheel gets made. In some cases, it might be cheaper to have a new wheel built and laced up than going out and purchasing a new one, especially if you have a good working hub. While lacing a wheel isn’t the most complex type of work, it does require some very specialized pieces of machinery. The truing of a wheel is also a bit of an art form to know how to tighten just the right amount on each spoke to make the wheel as balanced as possible.

Motorcycle Wheel Building 101

John Zamora

We started with a new wheel hoop from Harley-Davidson, a stock hub, and new spokes.

Motorcycle Wheel Building 101

John Zamora

First the stock hub was polished with steel wool to clean up nice and shiny.

Motorcycle Wheel Building 101

John Zamora

Using a specialized classic (read: old) piece of machinery, the spokes were cut to the proper length.

Motorcycle Wheel Building 101

John Zamora

This classic machine adds threads back into the spokes by rolling them in.

Motorcycle Wheel Building 101

John Zamora

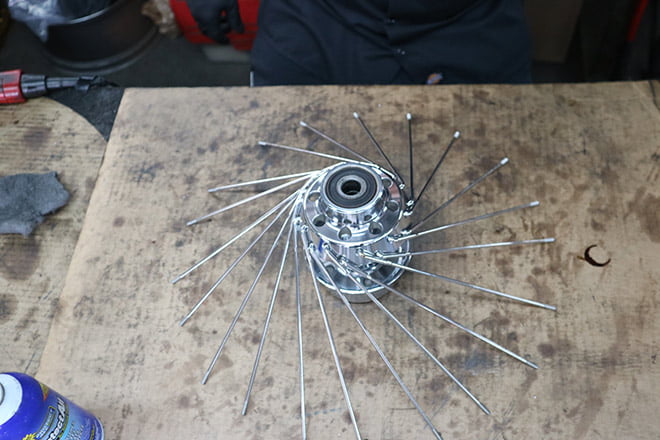

On a flat surface the spokes were put into place.

Motorcycle Wheel Building 101

John Zamora

Here’s with all the spokes installed on one side.

Motorcycle Wheel Building 101

John Zamora

Tape was added to the outer edge of the hoop to protect it from being scratched.

Motorcycle Wheel Building 101

John Zamora

Wheels are laced using a specific pattern depending on the size and number of spokes. This wheel was cross-four.

Motorcycle Wheel Building 101

John Zamora

Next all the spokes were snugged up, careful not to put too much tension.

Motorcycle Wheel Building 101

John Zamora

Once laced, the wheel was mounted to the balancing and truing stand.

Motorcycle Wheel Building 101

John Zamora

It’s important to add a little bit of oil to each spoke. Make sure when tightening you get an accurate torque. If not, they will unbind and become loose after a few miles.

Motorcycle Wheel Building 101

John Zamora

After removing the tape truing begins. This involves tightening of different spokes as you spin the wheel to create a balanced wheel (as possible). Knowing where and how much to tighten is a bit of an art.

Motorcycle Wheel Building 101

John Zamora

Finally the offset must be set. Each wheel has a slight offset depending on your application. The amount of offset was measured before the original wheel was taken apart.

Motorcycle Wheel Building 101

John Zamora

Once correctly trued, it spins like a top!

Motorcycle Wheel Building 101

John Zamora