Loctite Thread Lockers – Why Thread Lockers?

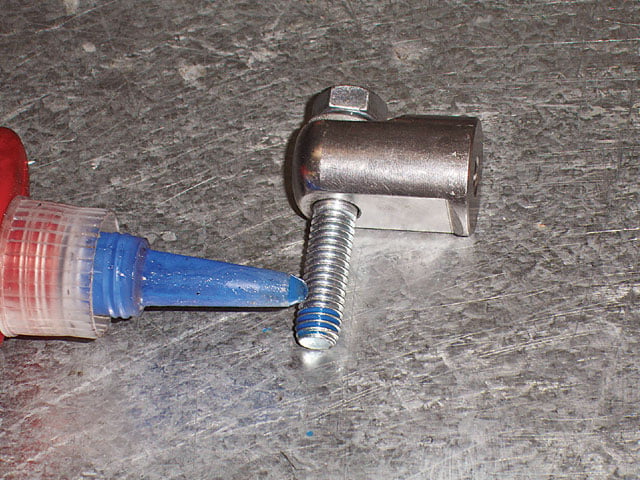

1. No matter what the brand (in this case, Permatex and good ol’ Loctite), threadlocker comes color-coded to make the right choice easy. For nearly any motorcycle application, all you need to remember is that low-strength Purple is for fasteners that are less than a quarter-inch in diameter and easily removable. Blue is the so-called medium-strength stuff, removable with handtools and the workhorse of the bunch. The really strong (practically permanent) grade is, of course, Red, and when they say it takes “extra effort” to remove stuff stuck on with this, that’s usually an understatement! Green is the least appreciated, and that’s a pity, because it should be the one we reach for before we’re in a situation that requires re-attaching anything, since a drop or two will penetrate into the threads of fasteners already in place-and keep ’em in place.

2. Anaerobic liquid resin isn’t just thread juice in a tube anymore. These days it comes in tidier, handier guises, such as convenient gel sticks, which apply a more even coat on fastener threads before they go into service-without dripping.

3. There’s more to it than meets the eye when it comes to non-threaded applications as well. For instance, these two tubes by the same manufacturer (Permatex) contain similar sealants, but they are definitely not for the same uses. The one on the left can do things such as replace snap rings and set screws, restore fit on press-fit bearings, and add up 2,800 psi shear strength on steel. The tube on the right fills gaps of up to .020 inch, withstands temps of 300 degrees F, and adds as much as 3,000 psi holding power. As the labels imply, one is for situations where things aren’t quite as tight as they should be. The other use is to hold parts together that are just worn-out and keep them in service long enough for new parts to arrive.

4. Of course, using fasteners without threadlocker is like using threadlocker without surface prep-the results aren’t nearly as good. Should you think this stuff doesn’t matter, perhaps you should be aware that (especially in cold weather) it not only cleans the threads like a good solvent but actually speeds up cure times of the threadlocker by 50 percent. Good to know when you need to get back on the road in a hurry.

5. Among the many OEM-specified liquid tools you should have in your toolbox is High-Temperature Thread Sealant (also referred to as PTFE) for applications such as oil-pipe fittings, cooler lines, switches and sensors, and a host of other situations where you need to screw a fine-thread fitting into a no-leaks-allowed hole.

6. By now it should be obvious that there are literally dozens of specialized threadlockers for the hundreds of fasteners that work hard for a living on your hog. It pays to do the research and find the one best suited to your particular project and situation. Although nowadays some aren’t even applied in the traditional way you see here, there has never been more need for these applications than there is on any Harley, let alone modern ones. Since they are OEM-specified for uses all over the machine, that means it’s time to honor an even older tradition-namely, doing the job right with the proper (anaerobic) tools.

The short answer to the question of “why threadlockers?” has to do with the fact that trying to properly tighten a nut or bolt to a specific torque value (let alone an unknown one) is an inconsistent, erratic process at best. Getting any fastener to do its job faithfully in spite of vibration and heat (meaning expansion, contraction, and outright distortion in dissimilar metals) can be very tricky.

First, we have to deal with the basic concept of how a bolt, screw, or practically any other threaded fastener really works. To come right down to it, they all function on the physics of tension (stretch and elasticity), not shear (sideways or lateral loading). In other words, the proper function of a bolt, let’s say, depends on its ability to clamp parts together, not to hang ’em like a picture from a wall.

Coupled with this fact is the questionable practice of attempting to get the precise amount of stretch required for a particular fastener to do its job without fail (or failing!) by using a torque wrench. For instance, is that supposed to be “dry” or “wet” torque? To get the same amount of stretch from a given fastener, the difference between wet and dry can require anything from 20-percent more torque to more than 100-percent increases! Depending on the material the fastener is made of and how it’s coated, it might even require a reduction in torque setting to work. Still, imperfect as it may be, using a torque wrench to snug up a bolt on your hog is the accepted method of getting it done the way the shop manual specifies it be done. Screws usually don’t have torque values at all, and reusing worn or dirty fasteners of any kind just makes for way too much guesswork when it comes to critical fasteners, wouldn’t you say? And on a Harley, what fastener isn’t critical?

The Motor Company understands this issue pretty well, and is moving more and more toward sophisticated fastener-tightening techniques that rely on creating the proper stretch in everything from head bolts to compensators to pulley nuts, while relying less and less on basic torque settings.

Knowing that, consider what happens when you are bolting things to your bike the old-fashioned way. The reality, regardless of the reading on your wrench, can be anything from, say, 16-24 lb-ft (if it’s even in that ballpark when you’re finished), so it’s not the most accurate gauge of fastener stretch. If you aren’t using a torque wrench, there’s simply no telling. Yet, in spite of vibration, heat, cold, and who knows what sort of demands on the fasteners, you hope things will stay put.

So, knowing it’s not quite as scientific and precise a process as it should be, how do you cover your bets and go from hope to near certainty?

Arguably the best way, bar none, is to apply a little dab of anaerobic liquid resin. Invented in the basement of a Trinity College chemistry professor and his son Robert back in 1953, the stuff came to market in 1956 known by the name coined by Robert’s wife-“Loctite.” Today, there are plenty of companies making this magic in a bottle. Permatex and Loctite, however, are the most famous makers of these sealants, which harden and expand in the absence of air and come in several different strengths and for practically any automotive application you can name. What makes so-called threadlockers so indispensable is this ability to dry and adhere to metals, particularly threaded metals in microscopic spaces.

In virtually every case where sheer heat (more than 400 degrees or so) doesn’t preclude its use, the factory recommends the use of a particular grade of threadlocker that’s suited to the specific task. One major reason (aside from vibration-proofing) is that threadlocker will tolerate a little variance in torque and will help compensate for slight irregularities in stretch from one fastener to another.

It’s simple: Using the right grade of threadlocker, in the right applications and in the right way, is the best insurance that your hardware will stay attached. It’s a major help (and minor miracle). So sit tight and lock on as we give you the rundown on using threadlocker to tighten up your ride.