Landmark Motorcycle Accessories’ Wheels

1. Here’s the bike with the stock Fat Boy solid disc wheels. They have got to go-sorry!

2. Landmark has a full line of chrome wheels and more than 28 different powdercoated colors to choose from as well. Then you can go with 80-spoke wheels or 40-spoke wheels. There are also 40 fat spokes that are the same style as the thin spokes, just with a fatter spoke. We wanted to stay with the flat black for now; the bike will get color later.

3. Doug Craig is the shop manager at Landmark and pulled all the parts we needed for these wheels. There is a chart to use so that you get the right-size wheels for your bike.

4. When it comes to rim sizes, Landmark has just about everything to handle thin tires and any wide-tire builds as well.

5. Doug pulled an 18×5.5-inch flat-black rim band and matching H-D replacement-size hub.

6. For H-D hub replacement wheels, Doug needed to press in the race for the Timken bearing.

7. This is going to be an 80 diamond-cut spoke wheel. To get started, all the spokes got the threaded end dipped in a special oil to help keep the threads from binding when being tightened down to the stainless-steel nipples.

8. There are 80 spokes; 40 are inside spokes, and 40 are outside spokes. The one on the left is the inside (A) spoke: a little longer nub end and a slightly tighter angle. The spoke on the right (B) is an outside spoke.

9. First, all the inside spokes were installed onto both sides of the hub. This is a crossover-four pattern; one spoke will cross four spokes to get to the rim band.

10. Then the inside spokes were installed to the rim band with the stainless-steel nipples. All the nipples were snugged, but not tightened yet.

11. Next, all the outside spokes were installed.

12. With all 80 spokes installed and snugged down, the wheel was then placed on a set stand, which allows the hub offset to get established. Knowing which bike (’98 Fat Boy) the wheels would be going on, all the tech needed to do was refer to the chart to find the offset.

13. Once the offset was in place, the wheel was tightened down. All the nipples were then tightened, placing the hub with the correct offset to the rim.

14. With the wheel and hub together, Doug got the wheel for truing. The wheel was placed in the truing stand, and then each spoke was tapped with a plastic punch to make sure that all the spokes were in place and not sitting out of the dimple.

15. First, all the outside spokes needed to be tightened to set the runout. Doug did this by placing a dial indicator along the rim band, adjusting eight spokes at a time, and getting the runout to be less than 0.020-inch from side to side. Note: Whatever is done on one side of the wheel, the opposite needs to get done to the other side-a push/pull adjustment.

16. Next, the hop was removed from the wheel. This is when a wheel gets adjusted too much to one side, making it impossible to balance. Doug had to get the hop down to less than 0.005-inch. It’s not easy, but necessary to get a good-handling wheel. Then all the spokes were torqued to 30 lb-in.

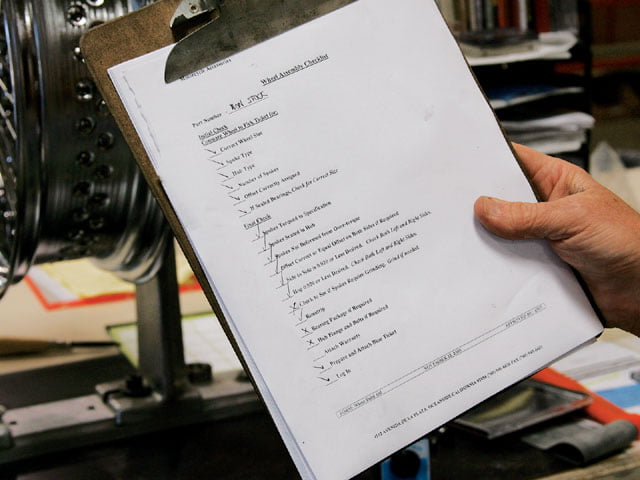

17. Once the wheel was trued, Doug ran down a checklist on every wheel before it was cleaned. He checked to see if it was the right wheel, the right spoke style, the right size, and the right color.

18. One last thing to check before is which bike it’s intended for. This is to ensure that the right wheel and bearings get placed in the box with the wheel. On the checklist it said that this wheel is a rear wheel for a ’98 H-D Fat Boy. It will get a set of Timken bearings for a 3/4-inch axle.

19. Next stop was off to Wheel Works in the city of Garden Grove, CA, to get the wheels and tires installed. The guys at Wheel Works wasted no time; the bike was on the lift, and the old wheels and tires were off the bike before we could get our camera out of the bag.

20. First, the bearings were packed with grease, and then the bearings, spacer, and seals were installed into the hubs.

21. For the front, a new Metzeler 18×130 tire and tube were installed onto the Landmark wheel, and an 18×140 was installed for the rear wheel.

22. Then the pulley was installed, along with the rotors.

23. Both wheels were then balanced before getting reinstalled on the bike.

24. Once both the wheels were back on the bike and aligned, the tires were inflated. Wheel Works now offers nitrogen for tires. This helps keep the tire pressure set and will not heat the same as air expanding the tire. To get more info on this, call and ask about how using nitrogen will help extend the life of your tires.

25. What the nitrogen machine does is evacuate all the air out of the tire first and then fill the tire back up with nitrogen. It may do it two times to make sure that it is more that 95-percent pure nitrogen in the tire. Once this is done, the machine beeps and holds the line ’til the caps are installed. The good thing is if you need to add a little air later, you can; it won’t hurt anything. It’s just a good idea to do the nitrogen from the start. NASCAR techs have been doing this for years.

26. And there you have it. With a new set of wheels, the bike already looks a hundred times better. Now all we need is some sheetmetal, a seat, and some paint.

One thing we can usually count on is how important the look of your bike is to you. If you didn’t build your bike from the ground up, you more than likely picked up a stock bike. If so, it may look like every other bike out there made by the same company, from Harley-Davidson to Big Dog. If you’re not interested in messing with the paint job, what else can you do to change up your bike’s look? What about wheels? A new set of wheels is one thing that can change the look of a bike without too much work and downtime. These days, almost every wheel company has custom and OEM replacement equipment. Landmark is one of these companies. It has a full line of spoke wheels to handle any custom job and all factory replacements.

We wanted to take on a bike makeover, starting with a new set of spoke wheels to change its look. We’ll then work our way to the sheetmetal, and eventually to the paint. The bike here was at one time a stock ’98 Fat Boy, but now it’s just a sort of mutant bike with style in every direction. To get started, we called Landmark Motorcycle Accessories in Oceanside, CA, to get a catalog of the company’s wheels. What we got was a lot more. Landmark has a full line of accessories, from mirrors, grips, and pegs to shift linkages and gas caps. The company also has a line of rotors and pulleys to go along with its spoke wheels. We gave the people at Landmark a call and let them know what we were doing with this bike. They told us to head on down so we could take a few photos as the wheels were getting assembled.