Kuryakyn’s Cheap Thrill

1. Before installing the rings on the pistons, we inserted each ring squarely into the cylinder and measured the end-gap of each ring with a feeler gauge. We were looking for 14-16 thousandths of gap. Too little end gap may cause the piston to scuff the cylinder and/or seize. Too large of a gap leads to high oil consumption and exhaust blowby.

2. We found the rings to have too small a gap, so they were opened up a bit with a rotary ring file.

3. Following placing the rings on each piston Matt placed each piston atop their respective rod before inserting the wristpin and securing the piston with a circlip on either side. Each circlip snaps into a groove that’s machined into the piston.

4. … inserting the wristpin and securing the piston with a circlip on either side. Each circlip snaps into a groove that’s machined into the piston.

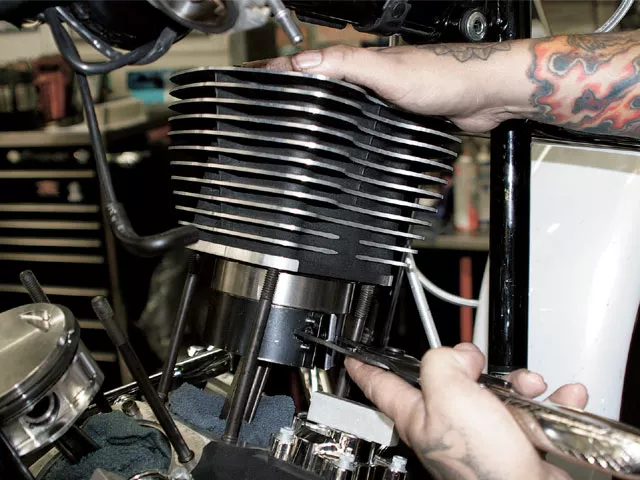

5. Before sliding the cylinder down over the piston, the rings were compressed with a ring compressor tool. We also made sure to put the O-ring on the bottom of each cylinder. This replaces the older style base gasket.

6. The same procedure was followed for the rear cylinder assembly. You can see in the bottom of the photo magnetic holders that hold the lifters up and out of the way.

7. Before putting on the heads we placed Cometic MLS (Multi-Layer Steel) Head Gaskets on top of the cylinders. These gaskets are made of three layers of stainless steel, with the outer layers embossed and coated with Viton rubber. The center layer gives the gasket strength and is designed to move with the head both vertically and horizontally to maintain a good seal. We used 0.040-inch gaskets but they are available in various thicknesses. We torqued each cylinder head to factory specs.

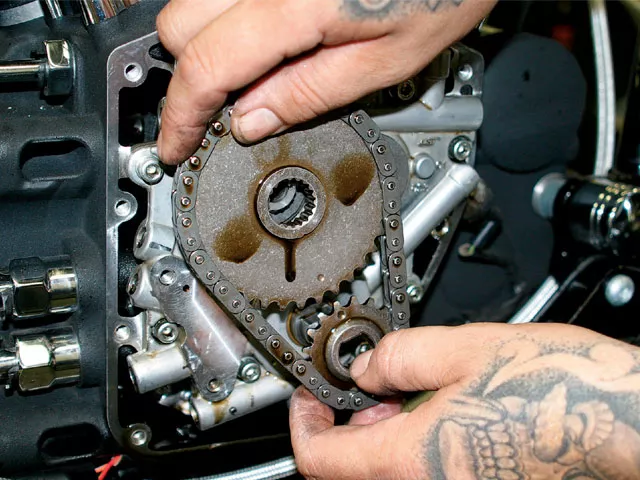

8. Before finishing the top end we tackled the cam chest area. The first thing we did was line up the timing marks (indented dots) on the camshafts before pressing the cams with the chain into the cam plate.

9. Once installed in the cam plate, both were inserted into the right side engine case. The ends of each cam sit in bearings in the engine case.

10. The cam plate was secured to the case and torqued to Factory specifications.

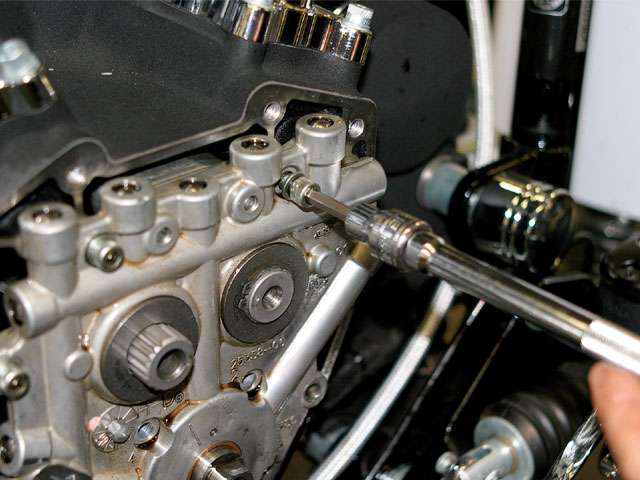

11. Next, Matt installed the upper primary cam sprocket and the lower crank sprocket onto their respective shafts, before fastening the hydraulic primary cam chain tensioner, followed by the chain guide.

12. …fastening the hydraulic primary cam chain tensioner, followed by the chain guide.

13. All that was left to finish the cam change was to install the Cometic cam gasket and cam cover.

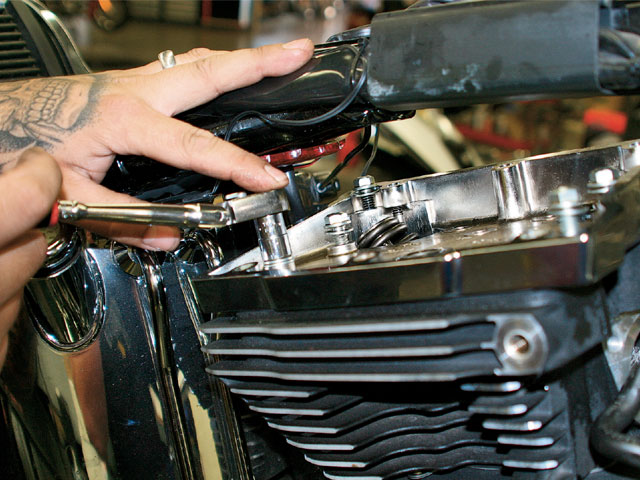

14. Moving back up top, Matt placed the Cometic EST (Extreme Sealing Technology) rocker housing gaskets into place.

15. Both rocker housings were installed and torqued.

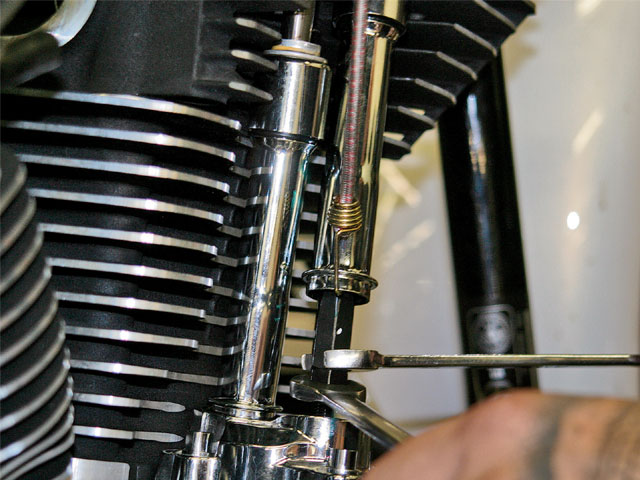

16. Before going any further, the Comp Cams Fast Times adjustable pushrods and tubes were prepared for installation. The adjustable pushrods were slid down through the rocker housing to rest on the lifters. These stiff pushrods are made of 4130 chromoly steel tubing with 0.049-inch wall thickness. The adjuster portion is made of 4140 high-strength steel with a hardened tip. Their adjustment design allows installation without disassembling rocker boxes, if the cam chest ever has to be opened again.

17. With the pushrods in place but not yet adjusted, the rocker arm support plate with the rockers was installed along with the breather assembly.

18. Installing both rocker covers finished up the top end.

19. After successively getting each pushrod to the desired length, Matt tightened the locknut on the pushrods.

20. Once each pushrod was adjusted, the pushrod tubes were extended and held with the spring cap retainers. This concluded the top-end/cam change part of the installation. Pipes, airbox, and breather assembly were left to get the bike running.

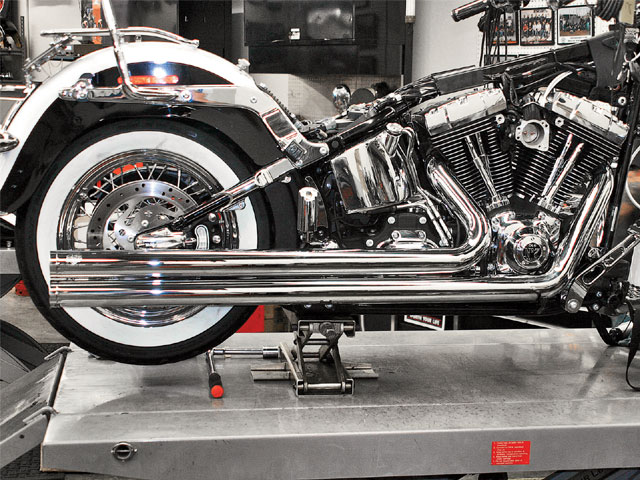

21. Kuryakyn worked with Cometic to develop the Wild Things Copper Exhaust Gaskets that won’t squeeze out into the exhaust port and restrict flow. One was placed into each head and then Matt bolted on the Vance & Hines Longshots.

22. …and then Matt bolted on the Vance & Hines Longshots.

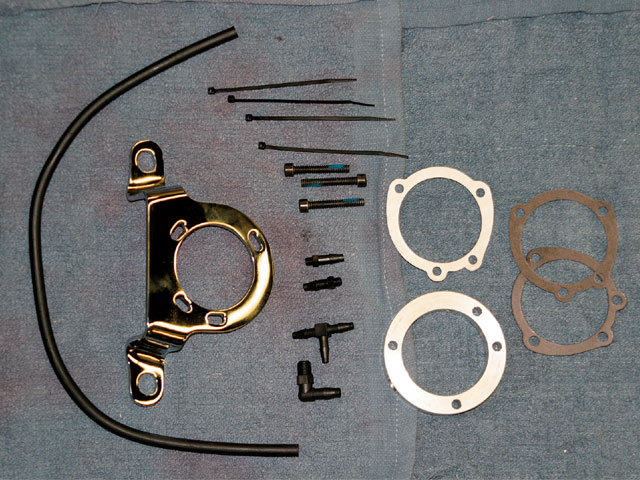

23. We would be using a Pro-R Hypercharger for air breathing duties. Here’s the backing plate, gaskets, and hardware needed for installation.

24. Attached to the backing plate is the inner half of the Hypercharger with attached butterflies. The interior shapes, especially the critical radius leading into the throttle body, have been carefully designed.

25. Before finishing the air cleaner, we installed the Bluegrass Breather banjo bolts into the heads. We’ll be routing these to a catch can later. It’s easier to get the breathers in now, before working space gets limited.

26. Next, a K&N; high-flow, washable foam filter element was placed into the inner half of the air cleaner. This filter assembly is one of the best flowing on the market and is capable of supplying enough air to even the highest output street motors.

27. The outer cover incorporates a scoop to direct air into the filter element. The Hyperchargers’ large frontal opening along with vacuum operated butterflies allows almost unrestricted airflow to the motor under high-load riding situations.

29. Breather oil was routed to the other side of the bike and into a catchtank. This sleek unit keeps oil out of your air cleaner and off of your bike. A simple bracket attached the tank to the horn mount.

29. Here’s the ’07 Deluxe waiting for some break-in miles before the dyno tuning.

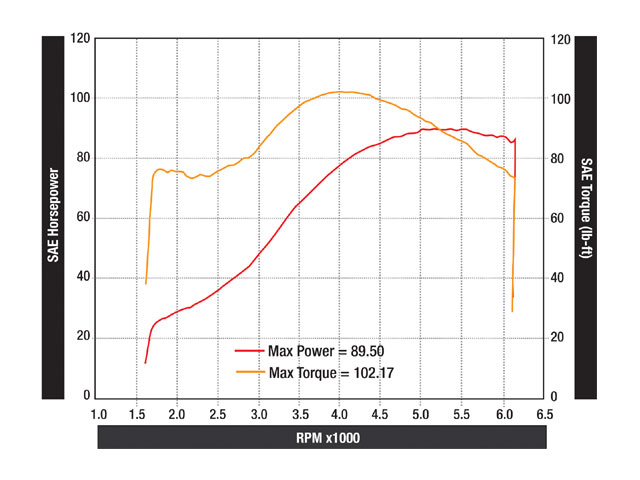

30. The bike baselined at 75.71 hp and 86.55 lb-ft of torque. After the install and tuning on the dyno, the bike pulled 89.50 hp and 102.17 lb-ft of torque. This was an increase of nearly 14 hp and almost 16 lb-ft of torque. These are decent numbers, but it’s important to note that every bike owner is different and will have a preference as to what EFI management system and pipes they want to run. We’ve heard from Kuryakyn as well as a few others that with an H-D Race Tuner and a good set of 2-into-1 pipes, they’ve seen over 100 hp and more than 110 lb-ft of torque from this kit.

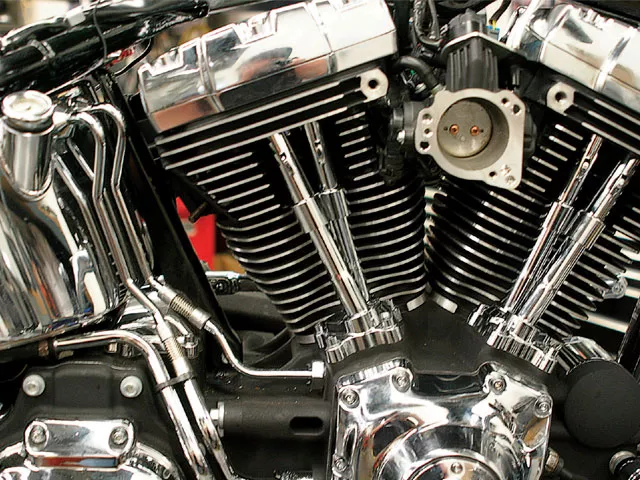

It seems like no matter how powerful and fast our motorcycles are, we just can’t resist the urge for more. You can increase the compression, flow the heads, juice up the cams, add nitrous or a blower-you get the idea. Nobody should have to settle for what took the Factory engineers years, if not decades, to design, hone (no pun intended), and perfect on our beloved machines. Size matters to us, from the duallies we drive to the 24-ounce ribeye down at BeefBarn.

Aside from the simple pipe/airbox modification, probably no other job is easier to perform or gains the greatest bang for the buck than increasing the displacement of the motor. Many companies produce big-bore pistons that work well with most of the stock H-D components. Combine the increase in cubic inches with a slightly more aggressive cam design and the aforementioned pipes and air cleaner, and you can have yourself a very dependable, streetworthy motor. Streetworthy means the bike has the torque where you want it, most likely in that sweet 2-4,000 rpm midrange where we spend most of our time. Combine that with reliability and the bike is going to be fun to ride. On the flip side are motors built for peak (high rpm) power numbers that often give up power in the low rpm range while reducing reliability and possibly running poorly on pump-gas.

Kuryakyn has all the bases covered as far as motor hop-ups are concerned. Their individual components and motor kits range from mild to wild. As the parts get more aggressive (as in high lift cams, billet heads, larger throttle bodies, etc.) they yield more power, but at an expense, not the least of which is economic. We contacted Kryakyn to see what they had for the more budget-minded consumer that seeks more power but still wants to retain stock-like rideability and reliability. We were starting with a stock 96ci ’07 Softail Deluxe that we wanted to bump up in size. They came up with the Cheap Thrills kit that fit the bill and in the process would increase displacement to 103 inches. Before we get into the specific parts, the following are the reasons we went with Kryakyn: gains in power and torque, a wide, usable powerbands easy starting without compression releases, quiet and smooth operation, can run on 91 octane pump gas without detonation (pinging), and performance-matched components.

The parts we received consisted of:

| • Wild Things 103ci Forged flat top pistons, rings, pins, clips #458 | $329.99 |

| * Wild Things TC-2D cams #460 | $349.99 |

| * Fast Times Pushrods # 438 | $124.99 |

| * Pro “R” Hypercharger # 9322 | $309.99 |

| * Bluegrass Breather # 9932 | $49.99 |

| * Catch Tank (for Bluegrass Breather) # 9931 | $49.99 |

| * Top End Gasket set # 480 | $89.99 |

| * Cam Service Gasket set # 481 | $29.99 |

| *.040-inch MLS Head Gaskets # 485 | $36.99 |

| * Wild Things Copper Exhaust Gaskets # 482 | $7.99 |

| Parts totaled | $1,379.90 |

The previous Big Bore Cylinder Honing story in this issue showed you how we took the stock 96-inch cylinders and bored and honed them to accommodate the larger 103 pistons. Once that was finished we took the Cheap Thrills parts to Harley-Davidson of Anaheim-Fullerton to have tech Matt Cortez rebuild the motor and install a set of Vance and Hines Long Shot pipes, along with a Power Commander. Once the bike was put back together, we put 1,000 miles on the bike before dyno-tuning the EFI to gain maximum power.

Check out how what can be done in a day’s worth of wrenching.

| Wild Things TC-2d Cam specifications | |||||

| Lift | Opening | Closing | Duration | Lobe Center | |

| Intake | .510 | 18 | 50 | 248 | 106 |

| Exhaust | .495 | 48 | 14 | 242 | 107 |

Squish and You:

Setting the squish is one of the most often overlooked procedures in building a performance engine. Squish is the clearance between the piston and the quench area around the combustion chamber at top dead center. More simply put, piston to head clearance.

When the piston approaches the head on the compression stroke, the air fuel mixture in the cylinder is squeezed out of the quench area towards the center of the combustion chamber. This creates a great deal of turbulence in the chamber. Turbulence is a good thing here keeping the fuel in suspension and creating a more homogenous mixture in the combustion chamber. These two things will result in a more complete burn and because the air fuel mixture is more consistent throughout the chamber, there is much less of a chance detonation will occur. Other benefits are increased power, better fuel mileage, and a crisper feeling and sounding engine.

The tighter your squish is set, the more benefits you will receive from this process. On the other hand, if your squish is set too loose, you can end up with a bike that performs poorly and has severe detonation (pinging) problems.

So how tight is too tight and how loose is too loose. For most Harleys .030-inch to .035-inch is the ideal piston to head clearance. Any closer and you run the risk of the piston hitting the head. Looser than .040-inch and the benefits of squish are lost.

Kuryakyn has raised the deck on their Wild Things pistons .015-inch to make getting that perfect .030 to .035-inch squish setting easier. Your cylinders won’t need to be shortened and/or the have need for super thin head gaskets.