K-Tech Tracker Suspension Upgrade

- Some minor upgrades can be done with the forks left on the bike, but because we were changing all the internals, the first step is to remove the forks from the motorcycle.

- Make sure to remove the cap carefully, as stock the factory tends to run a light spring with a lot of preload that causes the cap to eject once the pressure is released.

- After removing the spacer, the spring and fork oil are dumped into a safe container for disposal.

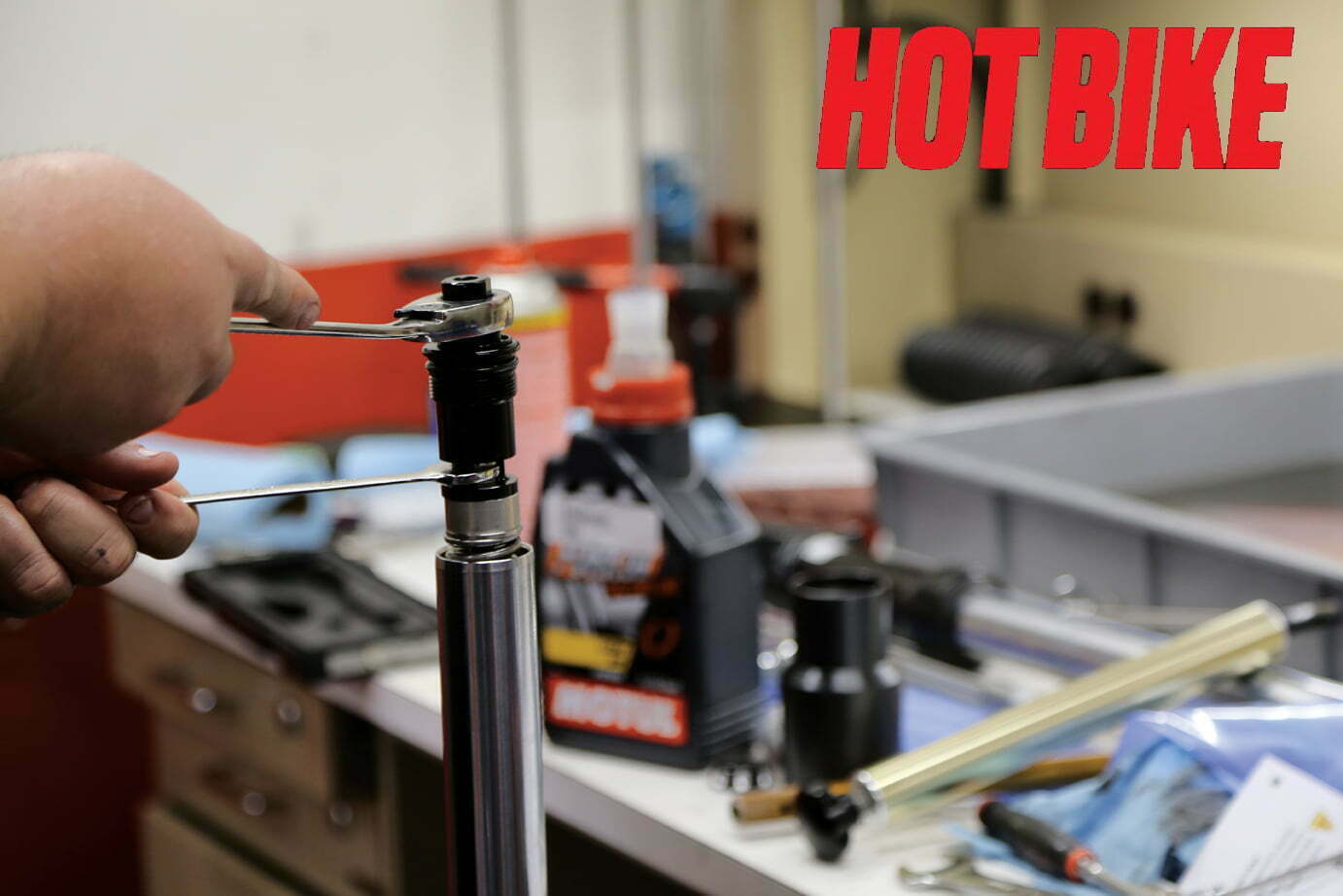

- Next, place the fork in a proper vise and loosen the lower bolt that holds the stock internals in place. If the bolt doesn’t want to come out, the dampner rod could be spinning. If that happens, temporarily reinstall the spring and spacer to hold it in place. Double-check that the copper washer was not left behind

- Remove the dust seal. A small clip holds in the fork seal. We used a heat gun to expand the aluminum tube to help remove the bushings more easily while slide hammering the two sections. The fork seal, washer, pressed-in bushing, and slider clip were all removed so only the tube and fork bottom were left. Next, thoroughly clean the tubes and bottoms.

- We used a little bit of seal grease on the fork tube to allow the bushings to slide on easier. Follow the instructions for the order of seals and washers. We used the fork seal driver tool to press the seals first, and then the bushings. It’s immensely important to add a little bit of grease on the seal to ensure it doesn’t bind. When you hear it get solid sound, stop. Finally, the circlip and dust seal hold it all in place.

- The kit has a compression and a rebound fork. The way to tell the difference is compression forks are black and rebound forks are natural in color. Lenny prefers to put the Rebound on the Right for “R and R.”

- After running the nut on all the way to the bottom with just a little bit of pressure, drop the cartridge kit in carefully. Make sure the old crush washer has been removed before replacing the bolt and new washer for the bolt in the bottom of the fork. Torque to recommended specifications.

- Shown here are the different spring choices. With two sizes supplied, you actually have a total of three choices. Running the 8.0 and 8.5 together will give you that rate, but running one of each will give you an 8.25 as the springs work in conjunction. With the K-Tech setup we have more spring-rate choices for more adjustment and flexibility.

- Next, set the height of the oil in the fork. Height is a more accurate way of measuring than volume to account for variance in fork design. We set the level and weight according to our K-Tech recommendations for our application. Make sure and first pump the fork by holding your hand over the opening to remove any air that may be in the fork or cartridge. Once you have dampning, pump the forks using the bleeding tool. Make sure and check instructions for spring in or spring out when setting level.

- When using two different springs rates, Lenny uses the heavier one on the right based on sitting on the bike. Right has bite. Left is light.

- Next, the cap must set by running the adjuster all the way out and then counting in 32 clicks. By running it all the way in, you’ll have 32 adjustments back out for the rod to move out. If you do both sides in the same manner, it guarantees your forks will be the same length. Use the bleeding tool to pull the fork to its top position for the retaining nut to hold. You may need a second set of hands to help do this.

- Screw the top adjuster all the way until it bottoms out. You’ll know you’ve reached this by gently trying to give it rebound and it won’t click. Once that touches, take it out a few clicks so you’re not jamming a needle down in it. Use the supplied tool that attaches to the top to make the final tightening.

- When done just verify that you have 32 clicks. Don’t put to much pressure to jam the needle.

- The same process is used to disassemble for the dampening (other) side of the fork.

- Again, follow the same procure to install other side of the cartridge using the steps before.

- Finally bolt the front forks back on the bike and reattach the wheel, fender, and brake.

- The Rear Razor shocks are much simpler to install. One bolt on top holds the shock in place and one on the bottom. Just unbolt the rear shocks and replace with the new ones.

There probably isn’t a better long-term investment for your motorcycle than to upgrade your suspension components. The stock suspension of a sportster is pretty basic and offers little-to-no adjustability. The result is a harsh ride, bumping and jarring over potholes and possible loss of control over rough surfaces. K-Tech Suspension might not be a household name in the V-twin market, but it is world renowned in the race world. For more than 10 years, it has been designing and developing top suspension components for race teams out of the United Kingdom. K-Tech recently released the Tracker fork cartridge kit for all Sportster models and other 39mm fork applications. The kit completely replaces the internals and upgrades them to an independent damping system that provides compression damping control in one leg, with rebound control in the other. Both legs have spring preload adjustment. For the rear, the Bullit shocks are made from forged aluminum and CNC’d with a spring-less nitrogen gas-charged design. The combined front and rear upgrades completely changed the handling characteristics of our sportster and allowed us to corner faster, brake harder, and feel more confident and comfortable in everyday and long-distance riding.

Suspension can be tricky and best left up to the pros, so we enlisted the help of suspension legend Lenny Albin, certified K-Tech technician, and the Motorcycle Service Center in Camarillo, California, to help make sure it all came together properly.

Sources:

K-Tech Suspension

Courtesy of Orient Express

The Motorcycle Service Centers