JIMS new 53mm Ellipse Throttle body

1. Here is the new JIMS 53mm Ellipse throttle body with manifold, flanges, gaskets, seals, and mounting hardware. Also shown is the new backing plate for the high-flow air filter.

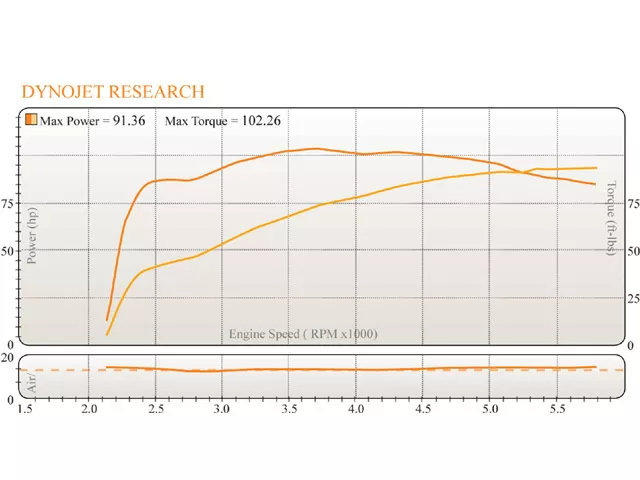

2. The first thing Nolen did was get a baseline dyno run to see just what was happening with the bike. What he found was at around 4,000-4,500 rpm the bike just fell flat, and had no top end. The max hp was 74.3 with 90 lb-ft of torque.

3. The battery was disconnected and the gas tank was removed, along with the stock air cleaner and backing plate. Then Nolen disconnected all the wires and unbolted the stock throttle body from the motor.

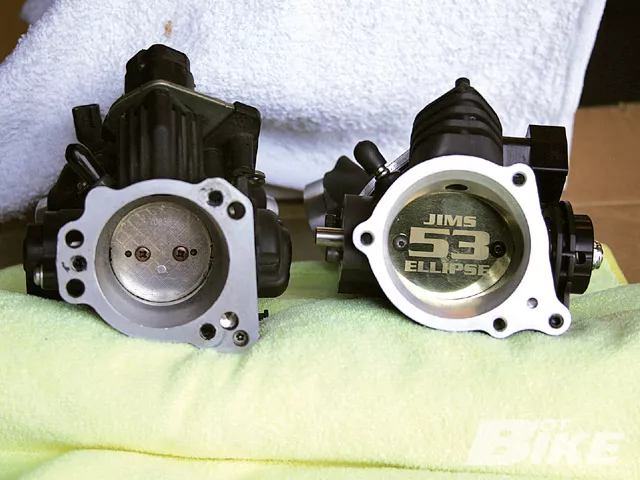

4. Here you can see the difference in the two throttle bodies, the stock 46mm on the left, and the new JIMS 53mm Ellipse on the right.

5. Nolen started assembling the JIMS throttle body by installing the large o-ring into the groove of the manifold before bolting it to the body. This will ensure a good seal and no intake leaks.

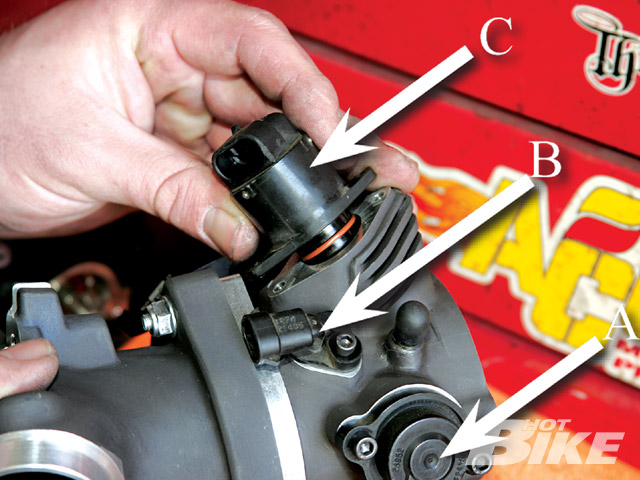

6. Next, Nolen removed all the induction components from the stock unit and installed them onto the new JIMS throttle body. First the throttle position sensor (A), then the temp sensor (B), followed by the idle control valve (C).

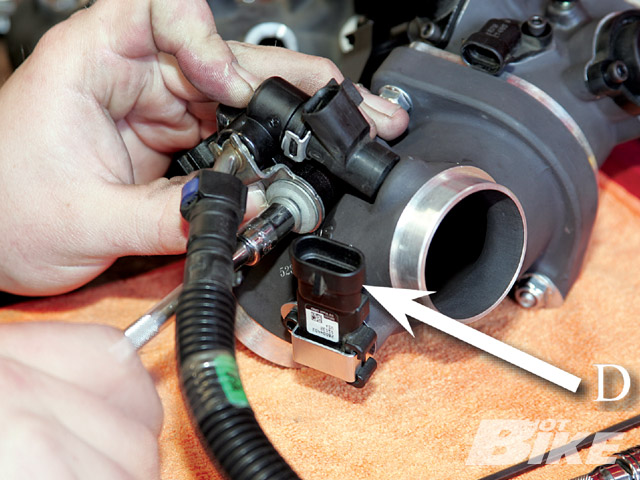

7. Then, the pressure sensor was installed (D), and the stock fuel injectors, fuel rail, and fuel supply tube.

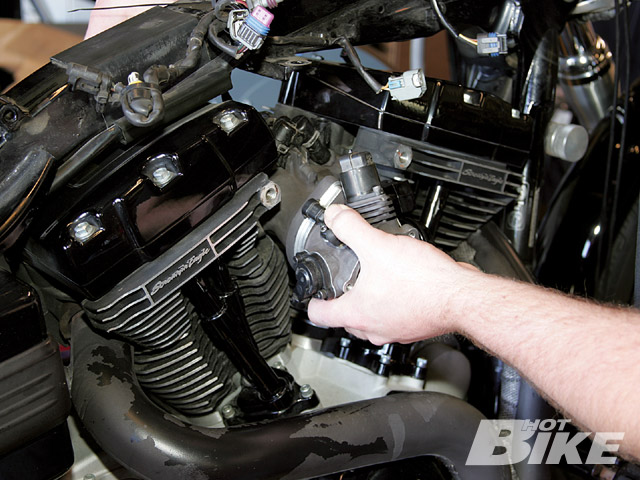

8. With everything together, the throttle body was placed on the engine. We found that we needed to remove about 1/8 inch of material from the intake flanges to get the body to sit further back and line up with the intake ports on the heads. Here, Nolen used a belt sander to ensure that the flanges were even. The manifold is designed with the flanges longer than stock so it can be used on different engines. With all the different manufacturers and engine sizes out there, JIMS wanted to make it so that with a little modification this throttle body would work with S&S; heads, H-D heads, and any other big-inch engine configurations.

9. Once we got the body to line up with the intake ports we needed to also remove a small amount of material from the top cylinder fins so that the bigger throttle body would allow the filter backing plate to line up. Once that was done the body was bolted in place to the heads and all the wires were reconnected.

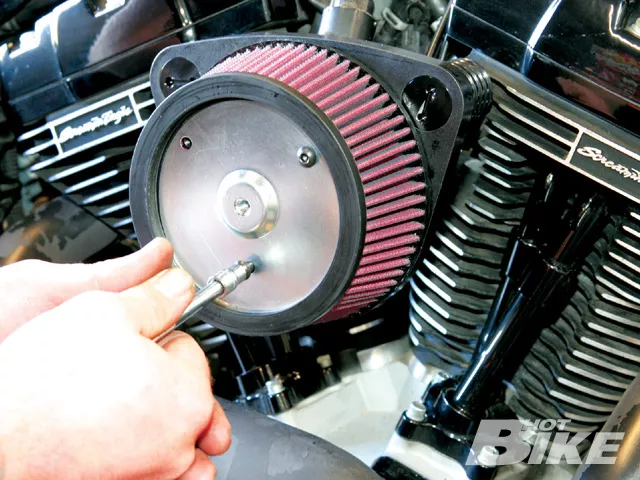

10. Next, the air filter backing plate was installed. There are two small o-rings that fit inside of the mounting bung on the plate. This will ensure a good seal once the breather bolts are on the heads not letting any oil blow by.

11. With the backing plate bolted in place the seal caps were installed using the supplied JIMS tool part #2233, then the high-flow air filter was bolted in place followed by the stock H-D filter cover.

12. The gas tank was reinstalled, the battery was reconnected, and the bike was ready for some more time on the dyno.

13. Once the bike was up to operating temp, and with a fresh base map the bike pulled 91.3-hp and 102.2 lb-ft of torque. You can see how well the torque curve was delivered to the bike through the 2,000- to 3,500-rpm range. Right off the line this bike has neck snapping, wheelie pulling torque. And the torque continued to steadily climb up into the 3,800-rpm range. The horsepower is a nice smooth increase from 2,100 and well into the top end. The one thing the owner liked was the bike was not falling off at the top-end like before and now the bike was ready for the owner and his riding style.

A few weeks ago we were out with some friends having a few cold ones when one of the road dogs who likes to experiment with his motor builds, started to tell us about his ’06 Dyna. He said he built the motor to a 106 ci with low compression pistons and a stroked flywheel assembly. Then he told us how he was having some issues, like the bike seemed to be falling flat at the top-end and he was thinking about throwing on a different throttle body. When we mentioned to him that JIMS had a new 53mm throttle body he was glad to volunteer up his bike to see if the 53mm throttle body would help his setup.

JIMS new 53mm throttle body is designed for high performance engines 95 ci or larger, and compatible with all O.E.M. electrical components and ignition systems. Also available is JIMS billet performance air cleaner backing plate kit to help get more fuel and air flowing into the bike throughout the power band. The throttle body can be ordered with or without the electronics, and the manifold comes with two different size flanges, one for 95 to 120ci engines, and one for 120ci and larger engines.

We stopped by Horn Cycles in Pomona, California to run the bike on the dyno and photograph the install. Shop tech Nolen was curious to see how this new throttle body would work out on this bike.