Jet-Hot Pipe Coating – Cool Your Pipes

1. To help keep track of the pipes, each piece is discreetly marked when it arrives at the plant.

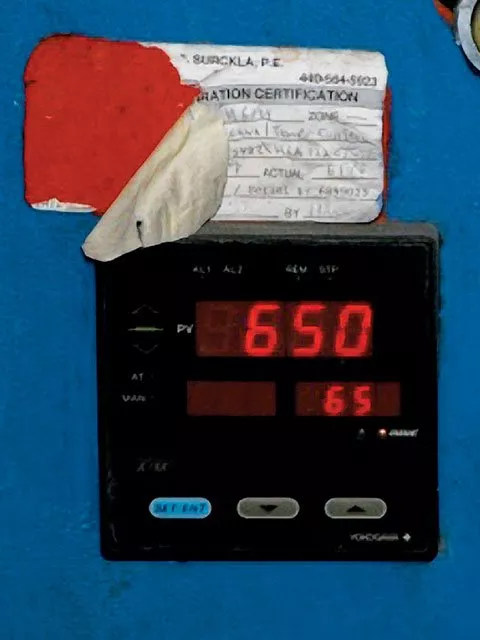

2. The process then begins by baking the pipes at 650 degrees F for around two hours to remove impurities from the material before the coating begins.

3. Out of the oven, the pipes are not sandblasted, but blasted with virgin aluminum oxide. The staff doesn’t use sand because it will rough up the metal too much and give you a textured coating when it is done. The aluminum oxide is very fine, and doesn’t destroy the metal while still removing the chrome plating, burnt heel marks, and anything else that may interfere with adherence of the coating.

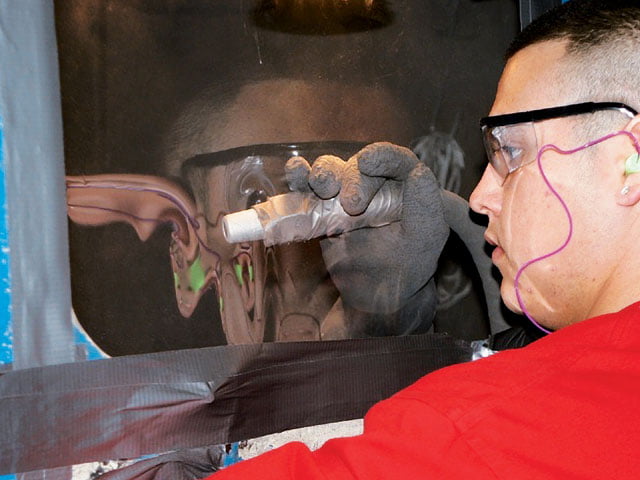

4. Once the blasting is finished, the interior coating is applied and later checked with fiber optics to make sure that the interior of the pipe is completely sealed. Here we see the interior coat being applied to the inside of the heat shield on this pipe.

5. The pipes are then hung on a conveyor that will slowly move them through the furnace for about 45 minutes at 650 degrees F to cure the interior coating.

6. Still on the conveyor, the pipes are given two exterior coats of the top-secret Sterling formula. Then they go back through the furnace for another 45 minutes.

7. The pipes are then prepped for the final color coats.

8. Meanwhile, the selected color is mixed.

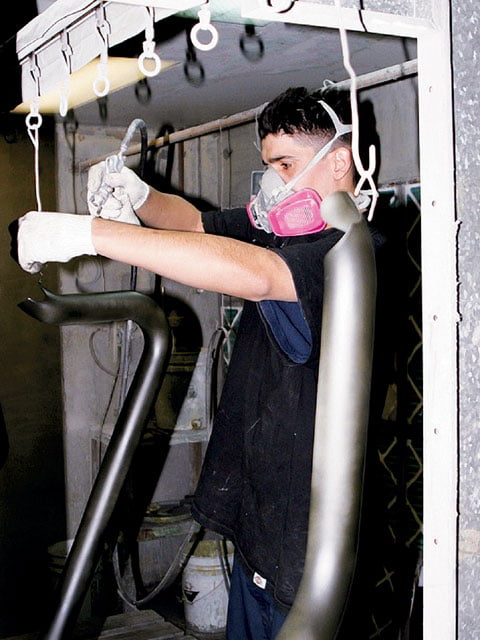

9. The final two exterior coats are then applied with the chosen finish color, which in this case was matte black.

10. Then it’s back to the furnace for the final bake.

11. At the end of the final baking or curing cycle, the pipes go to quality control, where the parts are subjected to a few instrumented tests to ensure that the chemically active coating was properly “activated.” Additionally, each piece is hand-inspected for any visual flaws or lightly coated spots.

12. And there it is: a set of pipes freshly coated with Jet-Hot’s matte black finish. Now there will be no worries about boot marks or bluing. Besides, the coating will help keep the rider’s legs from overheating while next to the pipe.

OK, here’s the scenario: Your pipes are turning blue, and you have burnt heel marks under the passenger pegs. You only have a couple of options to remedy this…let’s see, wrapping will do the job, but it’s pretty ugly. Heat shields are a possibility, but they’re still not the clean look you want…so what do you do?

Jet-Hot is trying to make this decision easy. While ceramic coating has been around for years, it has historically been dull. This year, Jet-Hot has introduced new coatings that are brighter than any ceramic and, most importantly, will not turn blue.

Jet-Hot has been around since 1983, and originally was exclusively a military subcontractor. Not long after that, the company branched into racing, and now Jet-Hot develops, manufactures, and applies a variety of coatings to suit a wide array of needs. While we already mentioned the good look of the new coatings, one of the interesting technical bits about this coating is that it is chemically active. This helps prevent the pipe from rusting even if you were to chip it off (which, by the way, is hard to do). It also keeps the pipes cooler. For cars, trucks, and bikes, the engineers at Jet-Hot found that one key to increased performance was coating the entire inside and outside of your pipes. This seals the pipes up against corrosion (remember, exhaust gasses are highly corrosive) and reduces heat transfer even more.

The makeup of the coating is a closely guarded secret, as are portions of the process used to apply it. However, the end result is that your pipes are sealed from any type of corrosion, the interior of the pipes is smoothed to allow for smoother airflow, and the coating cuts down heat transfer through the pipes. “Most people have us coat their pipes because they look great and don’t turn blue like chrome or stainless. However, after they’ve used us once, they keep coming back because of the dramatic heat reduction it gives. With our coating process, we’ve typically seen a reduction in heat ranging between 150-300 degrees compared to bare or chrome pipes,” stated Todd Beiswenger, director of marketing for Jet-Hot.

Jet-Hot offers several color options: blue, black (semi-gloss and matte), gray, and copper, but the company’s most popular color is called Sterling. Sterling is a shiny, quasi-chrome look that comes out looking like highly polished aluminum. With all the aluminum on bikes these days, it’s no wonder that Sterling is what most people are looking for-not to mention the fact that it’s also very easy to keep clean.

Musclecar enthusiasts and drag racers use the top-secret Sterling coating extensively, with 14-time NHRA Funny-Car champ John Force being one of the company’s most well-known clients.

Cost runs from $150 to $225, depending on pipe length, coating chosen, and the number of pieces you want done. It typically takes only five to 10 days to do the job at one of Jet-Hot’s regional facilities in Pennsylvania, Mississippi, and Arizona.

While parts of the Jet-Hot process are closely guarded, staffers did allow us to walk through their facility in Phoenix as we had these pipes coated. Here’s what we saw.