Hill Country Custom Cycles Ape Hanger Kit – Size Matters

1. Hill Country’s complete ape hanger kit includes Chubby Wild 1 bars, chrome hand controls pre-installed with internal wiring, Barnett stainless steel braided throttle and clutch cables, stainless steel braided brake line, chrome cable clamps, and electrical connectors.

2. Here’s our bike owner, Tommy, on his ’07 H-D Softail Custom with the stock 10-inch mini-apes. Maybe we can make him smile by the end of the day.

3. To get started with the installation, we set the bike in a wheel chock with a block under the kickstand and removed the seat and disconnected the negative battery terminal. Then we removed the tank console and unplugged all its connectors.

4. Here’s John pulling the tank to expose the wiring connectors along the framerail. Removing the tank involves separating and plugging the tank crossover hose, disconnecting the quick release on the fuel supply line, and disconnecting the fuel gauge.

5. We disconnected three plugs going to the handlebars: the 8-wire connector (gray) for the left controls, the 6-wire connector (black) for the right controls, and 6-wire multilock (black) for the front turn signals.

6. John loosened the throttle cables and disconnected them from the throttle body, while Tommy removed the mirrors and grips, which he reused, and the turn signals, which he relocated to the front forks. We also removed the brake line and disconnected the clutch cable from the left hand control.

7. Finally, we removed the upper clamps on the handlebar assembly and lifted off the stock bars.

8. We adjusted the stock risers about 1/8-inch to line them up to fit into the step down on the beefy Wild 1 bars. We used a bit of 3M Adhesive Remover to clean off the warning sticker.

9. The new bars were then placed on the frontend just begging for cables and connections.

10. To begin the electrical work, John removed the connectors from the old hand control wiring. He pulled back the black wire holder and the orange seal to expose the wires.

11. Then John pulled the white inner pin-lock up with needle nose pliers. Next he inserted a special terminal remover-a small paper clip-into the small round hole next to each wire pin to release the pin lock and pull the wire from the back of the connector. This was repeated for all pins and both connectors.

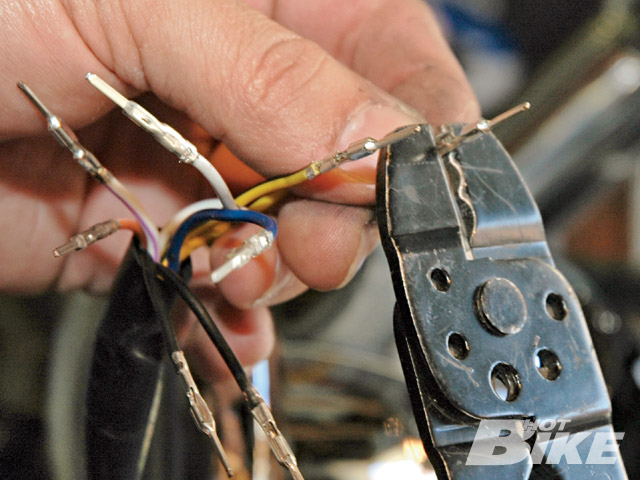

12. John sorted and inspected the wires for the new left hand control. The wires were nicely cut and tinned ready for pin terminals. Plus all the wires were color coded to match the existing wiring harness.

13. New pin terminals were required to install the connectors on the new hand control wires. So John crimped a pin terminal to the end of each wire on the new hand controls.

14. To insert the wire pins, John followed the wire color and pinhole number specifications from the service manual-wiring diagram. If you don’t have a service manual, use the matching wiring harness connector as a guide to pair up the same color wires. Insert each pin, insert the orange seal, snap on the black wire holder, and press in the white inner pin-lock to complete the connector.

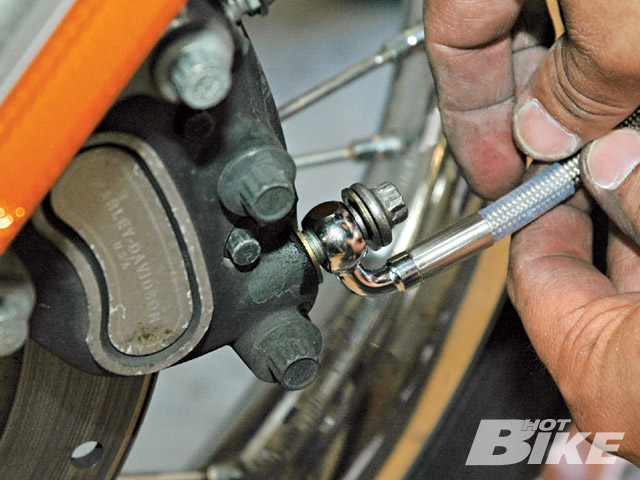

15. Next, we installed the new braided brake line to the banjo bolts on the front brake caliper and the master cylinder reservoir and torqued the 12-point bolts to 17-22 lb-ft.

16. Here we installed the throttle grip and attached the throttle and idle cables. In the handlebar housing, the throttle cable goes to the front and the idle cable goes to the rear. The throttle cable has a larger diameter insert than the idle cable. On the throttle body (not pictured) the throttle cable sleeve goes into the inside (or bike side) hole of the throttle wheel and the idle cable with spring goes in the outside hole.

17. Tommy installed the clutch cable into the left hand control and routed the cable down the bar and to the right side of the bike. Note: Take extra time to route all cables so that the lines are not kinked or pinched and there is no binding over the full side-to-side movement of the frontend.

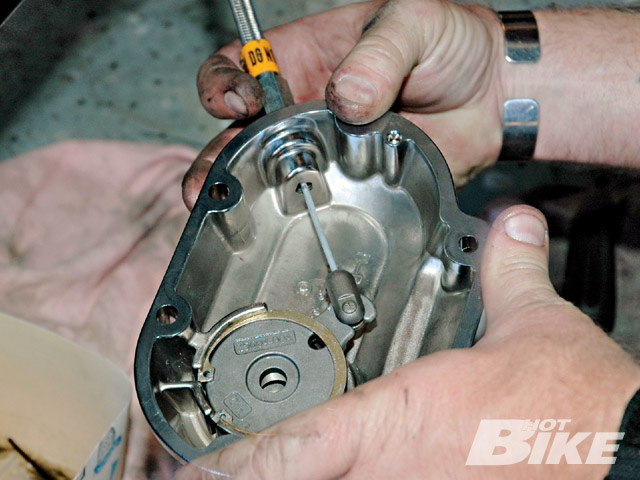

18. We removed the clutch release cover from the right side of the transmission, disconnected the old clutch cable, and connected the new cable.

19. After Tommy reinstalled the turn signals to the lower fork bracket using a relocator kit, the three amigos got started reinstalling the fuel tank. First, we connected the console and tested all the switches to be sure our connectors worked. Then, after installing the tank, we attached the console. Finally, with the seat installed, Tommy got to hang on the new bars while John adjusted the handlebar and hand control positions.

20. After John torqued the handlebar clamp bolts to 16-20 lb-ft, and tightened the handle controls and adjusted the throttle and clutch cables, we filled the master cylinder with dot 4 fluid and bled the front brakes. Once we finished the install, everyone agreed the bars looked great. And, this was the look Tommy was after: High quality parts, beautiful chrome finish, clean style, and hands-at-the-shoulder look.

After our friend Tommy said he wanted a more aggressive look than what he got with the stock, 10-inch mini-apes on his ’07 H-D Softail Custom, we called Hill Country Custom Cycles for one of its Wild 1 16-inch Ape Hanger Kits (MSRP $629.95). The kit is designed to fit any Harley model ’90-08 (except ’08 Touring models, and fairing and Springer models). The core of the kit is a good-looking set of Wild 1 Chubby ape hangers with 1 1/4-inch thick bars. The beauty of the kit is that it includes switches, chrome controls, and stainless cables so you don’t have to play the guess-the-correct-cable-length game. For convenience Hill Country pre-installs the handlebar switches with internal wiring. The 1 1/4-inch bars are reduced in size to 1-inch at the riser clamp and grip ends to accept stock risers, controls, and grips.

When the kit arrived, we set up a “three amigos wrench day” in our garage with riding buddies John and Jeff joining Tommy to install the taller bars. Replacing the handlebars on a motorcycle is not a difficult mechanical task, but it can be tedious, especially if you have to re-wire the electrical connectors, disconnect and reconnect all the controls, replace the brake line and bleed the brakes. Access to a service manual is advised.HB