Harley-Davidson Night Train Hop-Up

1. The bike was placed on the lift, and service tech Brian Breeland got started by removing the stock frontend. First he pulled the fender, the axle and tire, then the brake caliper. He loosened the pinch bolts and slid the fork legs from the triple trees.

2. The gas tank was removed from the bike; we needed to get to the wires later when the bars got installed, so Brian pulled the tank just to make sure nothing happened to the paint. Then the old handlebars and triple trees were removed. At that time Brian pulled out the old bearing race and installed a new set, top and bottom.

3. OK, here is the new black inverted fork kit. Once we opened the box we found new trees, fork legs, axle, spacers, washers, bearings, and top covers.

4. Brian installed the new greased bearing to the fork stem, then slid the stem and tree into the frame neck. The top bearing was installed onto the neck stem along with the dust cover and the adjusting nut. The adjusting nut was tightened down until there was no free-play up and down and the lower tree moved side to side without any resistance.

5. Then the top tree (fork bracket as it is called) was bolted to the neck stem, making sure the lock washer engaged the slot in the top tree. The stem nut was installed loosely until the fork legs were installed for alignment.

6. Next, the fork legs were installed into the trees. Brian slid the fork legs up into the trees until the top of the leg bottomed out into the tree. There is a tapered lip that the legs sit in.

7. With the leg in place, Brian tightened the pinch bolts of the upper and lower trees, and repeated this for both sides.

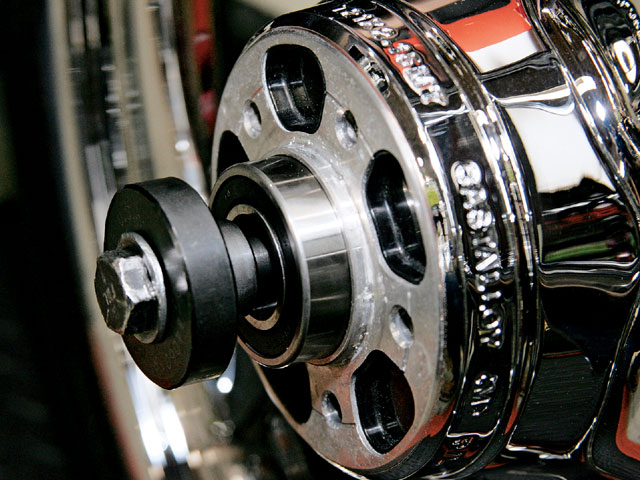

8. Next was the installation of the new 21-inch chrome Reaper wheel. This is a good-looking wheel; we just wished it was offered in black. Brian installed a new tire, and then got started on wheel spacing.

9. The new Reaper can be used on any of the Softail models. For proper spacing this wheel kit requires separate purchase of a model-specific wheel bearing Installation Kit. Check with your dealer or proper service manual. For this bike, we needed to install part # 43833-07, then placed the wheel on the frontend to check that it was centered along with the fender.

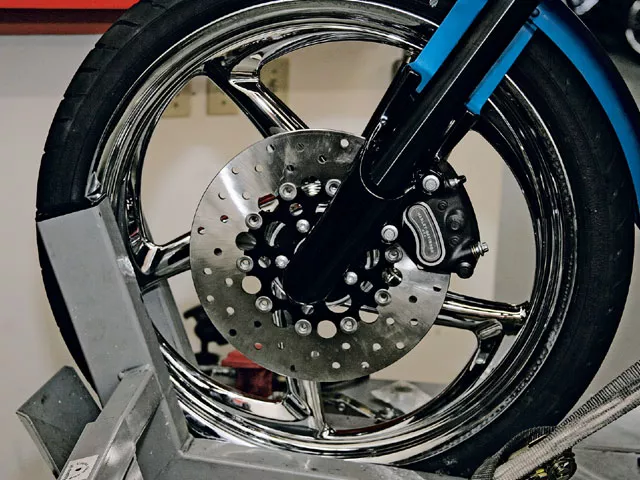

10. Brian installed a new floating brake rotor to the wheel, then placed the wheel back on the bike. With the wheel in place, he installed the caliper making sure that the wheel was still in the center of the frame and that the caliper was straight and not binding up on the rotor.

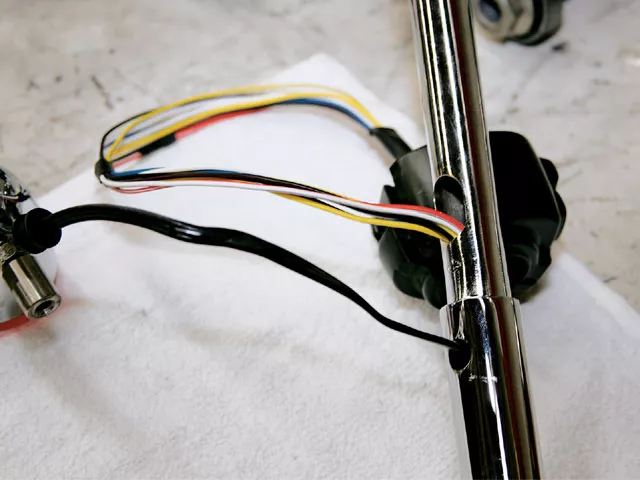

11. Next, Brian started on the new Street Slammer drag bar with 7-inch integrated risers. This chrome-plated 1-1/4-inch fat bar is factory drilled to accept hidden control wires for a clean custom look. This part took the most time; Brian was real careful when pulling the wires though the bars so as not to cut or pinch them.

12. Here you can see that there are two holes for wires to run-one for the controls, and one for the turn signals. Each one needed to get routed, and then extended about 6-inches. Note: Do not forget the rubber grommets.

13. With all the wire run through the bars, Brian installed the controls, new contoured grips, black levers, and black mirrors. The blinkers will be relocated from the fork tubes to the bottom of the hand controls, and replace the amber lens covers with new smoked covers.

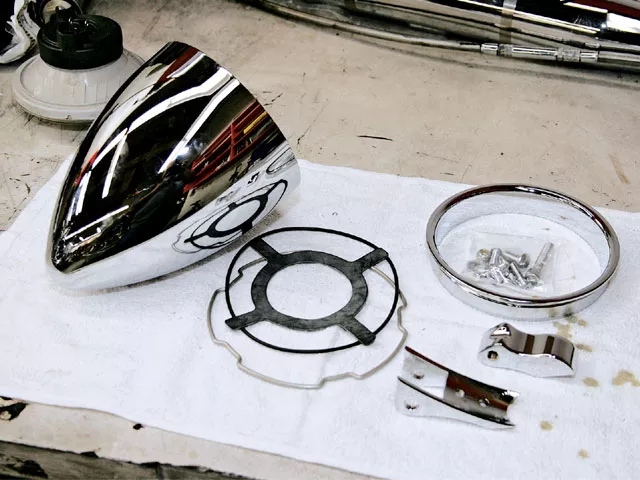

14. Next Brian assembled the new billet headlight kit; the chrome surfaces and the close-fitting inner trim ring create the appearance of a one-piece design. The kit includes chrome-plated mounting hardware and a custom billet mount. He needed to pull apart the stock bulb and wiring for this housing.

15. At this point the handlebars were in place, so Brian reconnected all the wires, placed the gas tank back on the bike, then routed and installed the new throttle cables, clutch cable, and brake line.

16. Next, Brian bled all the air bubbles from the brake lines.

17. We also swapped out the stock speedometer for a new speedo/tach gauge. This is a one-piece direct replacement for the ’07 and later that needs to be calibrated for the proper mileage of the bike. This has to be done at the dealership.

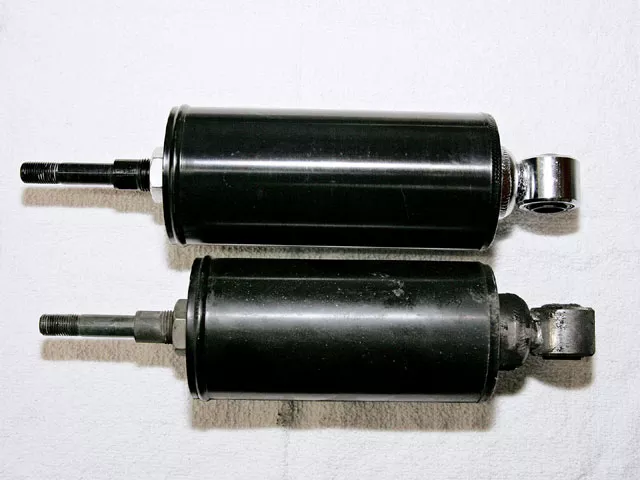

18. We also wanted to lower the rear of the bike with a set of shocks, so Brian removed the stock shocks from the bike by unbolting them from the frame and the swingarm and pulling them out from under the bike.

19. You can see that the new shocks are longer. This shock lowers the seat height approximately 3/4-inch while preserving ride quality, and features multi-staged damping to insure optimal performance.

20. We started with a seat height of 25 inches at the bottom of the fender to the ground, and now we are at 24 inches.

21. With everything back together, Brian took the bike out for a test ride and checked the handling and braking. After taking the bike out for a ride, the frontend handled well, but the bars are a bit low. We felt that the frontend looked more custom, but would have liked to see the headlight and handlebars blacked out as well. We will call Harley-Davidson to see if they don’t mind if we send them out to get powdercoated black. Call your local dealership for prices and installation costs.

We are moving onto the next part of the Night Train hop-up. In this installment, we wanted to lower the bike and swap out the stock chrome frontend with the new, black inverted frontend and also wanted to see what a new set of handlebars would add to the look. Ever since we started this project, we have received letters and e-mail from readers telling us what they want to see from this bike, and we feel the same way as you: It’s a Night Train, and it should be blacked out. We put a list together of some parts we felt would give it that look, and a blacked out inverted frontend was the first thing that we thought would contribute. With that in mind, we felt we needed to lower the rear fender to the tire a bit so it wouldn’t look too high. We stopped at Pomona Harley-Davidson in Montclair, California, to get some parts installed on the Night Train.