H-D’s Hydraulic Tensioner and Oil Pump Upgrade

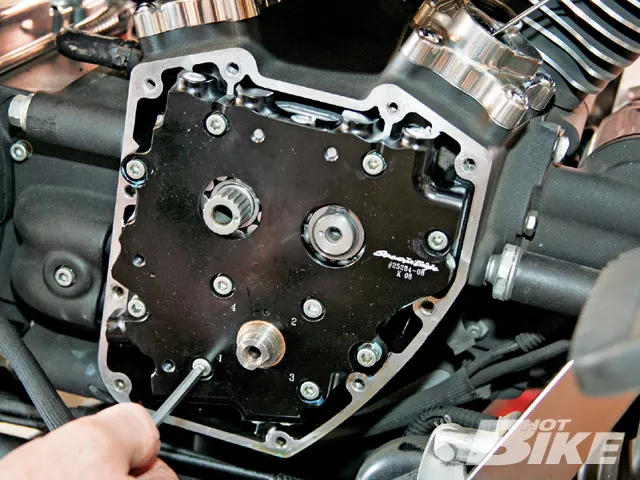

1. The kit includes the Screamin’ Eagle billet cam plate which is precision machined from 6061 aluminum and anodized for durability, the high volume oil pump, hydraulic cam chain tensioners, bearing retainer plate and chain guide riser, along with six different sized shaft bearings.

2. To get started the rocker boxes, rocker assembly, and the pushrods were removed.

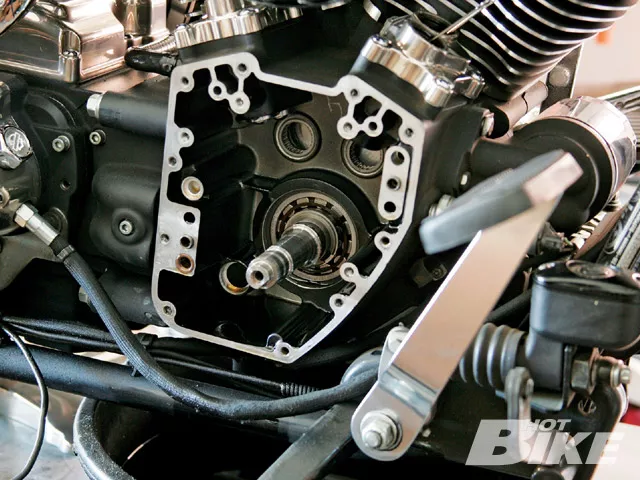

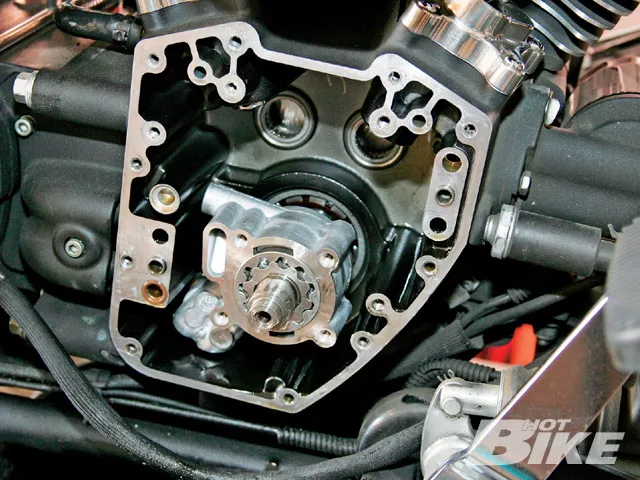

3. Next, the cam cover was removed to gain access to the camshaft sprocket and chain. Once removed, Brian then unbolted the cam plate and pulled both the plate and the oil pump as one piece.

4. Once everything was out Brian inspected the main- shaft for any wear or discoloring, then did the same for the two cam bearings. This set was like new and did not need to be changed. Also all the oil ports and passages were inspected and everything checked out fine.

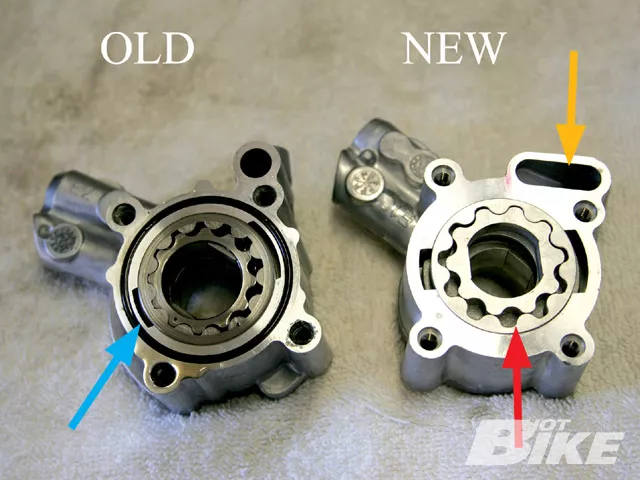

5. Here you can see the difference between the two pumps. First, the shape of the feed rotors on the newer pump, the cogs are rounder and the opening to the rotor is bigger for more oil (red arrow). Also, the flow port is bigger (yellow arrow) so more oil flows through. And with the new billet plate and improved design for a perfect fit you will notice there is no need for the inner O-ring, like on the old pump(blue arrow).

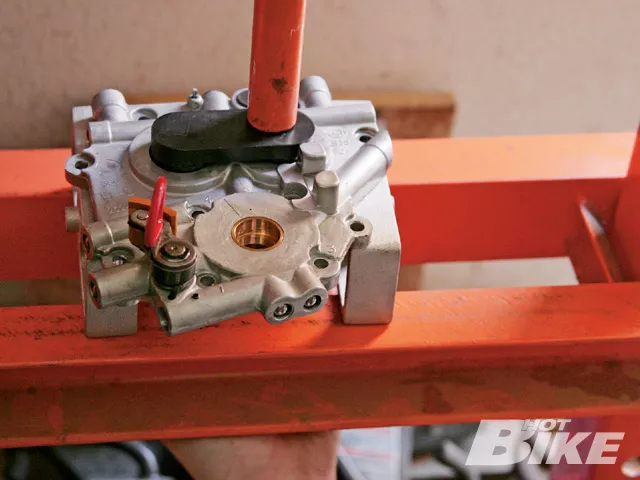

6. Next, Brian removed the cams from the stock cam plate with the help of a press.

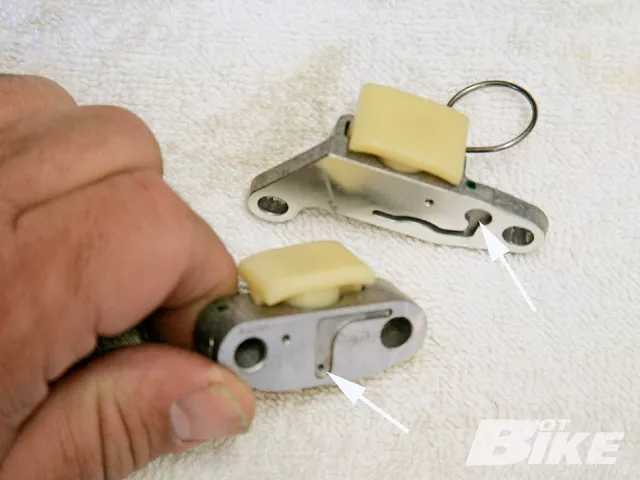

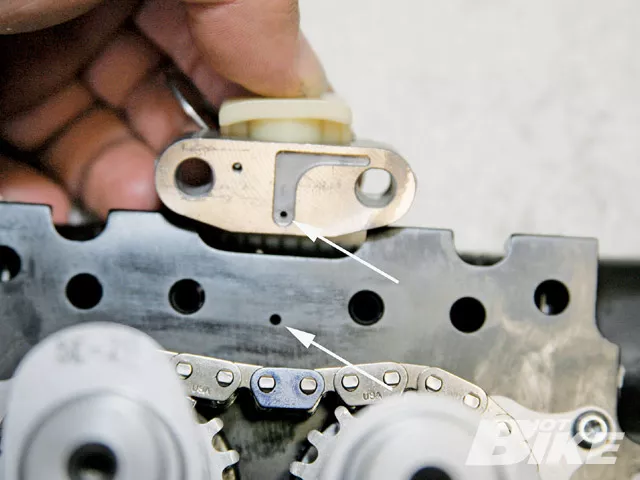

7. The second part of this upgrade is the hydraulic cam chain tensioner; here is a look at the spring style with the load pin in place. The pin is used to unload the tension from the cam chain so that the cams can be removed.

8. Here are the new hydraulic cam chain tensioners, you can see there are no springs. How they work is as the motor builds up the oil pressure, oil is also pushed into the passages of the tensioners (arrows), pushing and holding the wear pads to the cam chain.

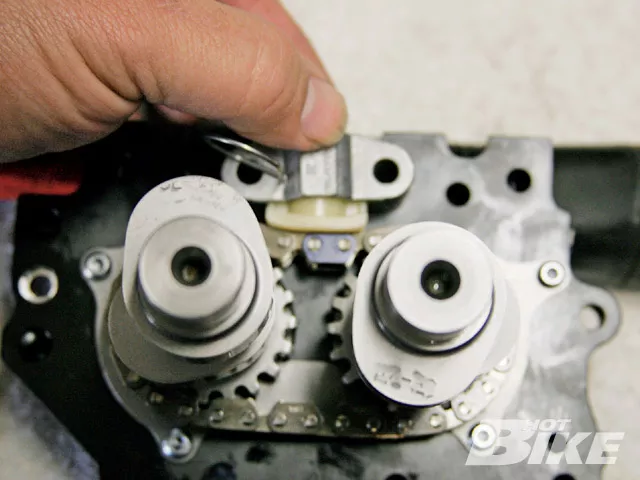

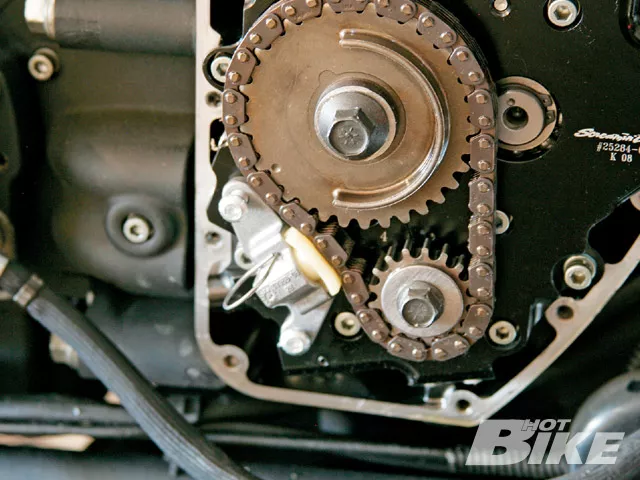

9. Next, the cams and chain were lined up with the timing marks then installed along with new bearings into the new billet cam plate.

10. This is where the inner hydraulic cam chain tensioners mount to the plate and how the oil flow ports lineup (arrows).

11. Here is how it will mount and the pad will hold tension on the chain.

12. Brian installed a new oil seal O-ring into the oil port of the case, then installed the new style oil pump

13. …followed by the new billet cam support plate.

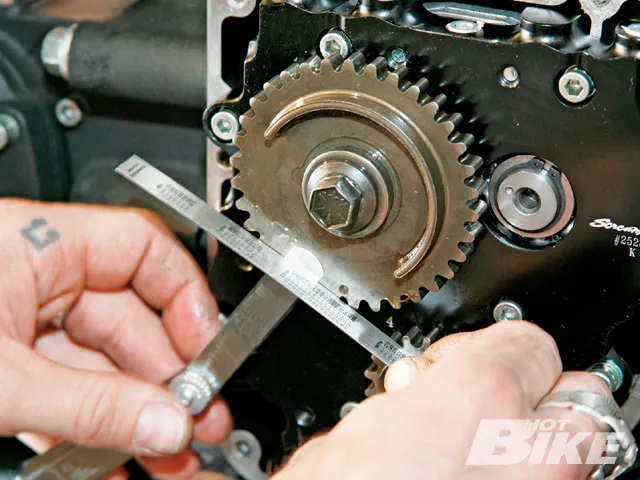

14. Once the plate was torqued to 90 in-lb Brian needed to install the camshaft sprockets. With a small straight edge and a set of feeler gauges he was able to determine that 0.357 spacer was needed to ensure that both sprockets were aligned.

15. Then the camshaft drive sprockets, the primary drive chain, and the outer hydraulic chain tensioners were installed.

16. Wrapping up this install Brian reinstalled the pushrods, the rocker assembly, lifters, and the rocker boxes. Once the lifters had time to bleed down Brian adjusted the pushrods to factory spec.

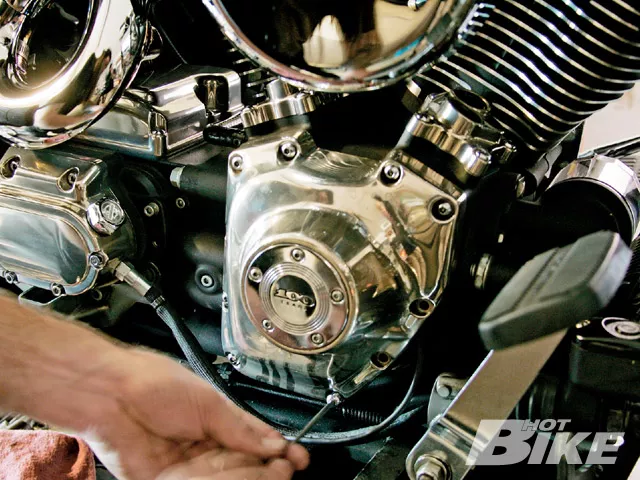

17. Lastly the cam cover and the exhaust was reinstalled. The bike was wiped down then taken out for a test run. As soon as the bike started up it was easy to see that there was a difference in the motor. The idle seemed smoother but the oil pressure at idle was up 10 PSI at cold start up. This is what we found after testing the bike.

Not that we need to point out how lucky we are at HOT BIKE, but we are very fortunate to get our hands on some of the newest and coolest things out there in V-Twin land. We still get excited when a box of new parts shows up on our doorstep. But, our favorite part of receiving these cool parts is bolting them onto a bike for you to check out.

For example, we received this Screamin’ Eagle Hydraulic Cam Chain Tensioner Plate Upgrade Kit from Harley-Davidson. This kit updates the cam chain tensioner of your early-model Twin Cam engine to the latest design, as featured on the Twin Cam 96ci engine. The billet cam support plate has been designed to allow the installation of the late-model hydraulic cam chain tensioners to early Twin Cam-equipped models with the use of your existing cams, and is pre-assembled with crankshaft bushing and an oil pressure relief valve. The hydraulic cam chain tensioners will significantly outlast the spring-loaded tensioners, and are an ideal addition to an engine modified for improved performance. In addition, if needed the ’02-06 models feature the late model single row front cam chain and sprockets (’99-01 models use the existing front silent chain). The kit includes the improved late-model oil pump that increases flow by 8 percent and scavenging by 22 percent for better cooling. This improves the stock oiling system to increase oil flow to piston oil jets, cam chain tensioners, pinion shaft bearings and connecting rod bearings

The kit fits ’99-06 Touring, ’00-06 Softail and ’99-05 Dyna models, and retails for $429.95. We installed the kit on a ’01 Ultra Classic with a little over 25,000 miles. The owner Brian happens to be a Harley tech and was glad to let us use his bike for the install.

| Before the install | After the install | |

| Cold idle | 30psi | 40psi |

| Warm idle | 18psi | 32psi |

| Cold at 2750 rpm | 32psi | 50psi |

| Warm at 2750 rpm | 30psi | 42psi |