Custom Harley Davidson Evo Engine – 96-Inch Evo Build

One of the features of the boxes is their stout design and integral rocker stanchions. By doing away with a separate stanchion, TP’s boxes do an excellent job of retaining the valvetrain’s intended geometry.

TP Engineering’s Pro-Vent rocker box is designed as a two-piece system, machined from billet. The boxes are available with either the TP logo or a ball-milled design.

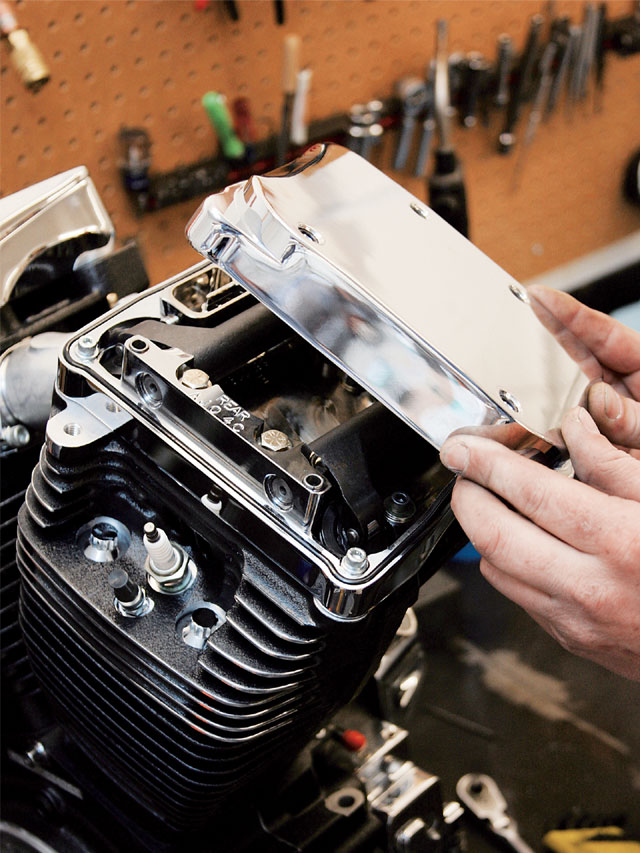

With the included metal gasket in place, Eric placed the rocker-box bottom on the rear head.

Then Eric applied blue thread locker to two of the three 1/4-inch bolts for the rear box.

The 1/4-inch bolts were then torqued to 110 lb-in.

Here is a good look at the top side of the Pro-Series roller rockers.

With the rocker flipped upside down, you get a good look at the roller portion of the assembly. For lubrication purposes, oil flows out of the forged arm and is deposited on the roller, helping to maintain a long life.

At the other end of the roller, you can see a dimple where the pushrod will seat. The hole in the center of the dimple is designed to carry oil from the pushrod along the internals of the rocker on its way to the tip of the roller.

Tolerances between the rocker arm and the stanchion were held very tightly, leading to a good fit between the two parts.

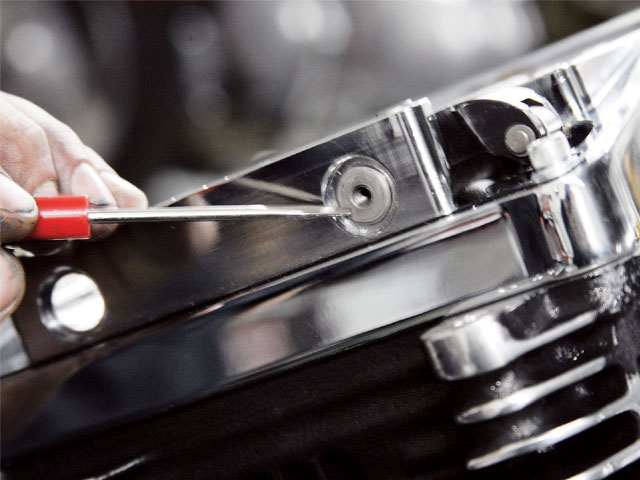

Just a little wiggling of the rocker was all that was needed to fit the rocker shaft in place. Photo No. 6 shows a notch ground into the shaft. This notch lines up with one of the mounting holes in the bottom box.

5/16 x 2-1/2-inch mounting bolts pass through the notch, securing it in place.

TP machines the rocker shafts with a threaded hole in the end. This hole makes removal of the shaft a snap by threading in a bolt and pulling on it.

After installing the O-ring gasket in the bottom box and the die-cut gasket in the top box, Eric set the rocker-box top in place.

It was then secured by four 1/4-inch flathead screws.

This is one of the two pairs of the Andrews Products EV80 EZ-Install pushrods.

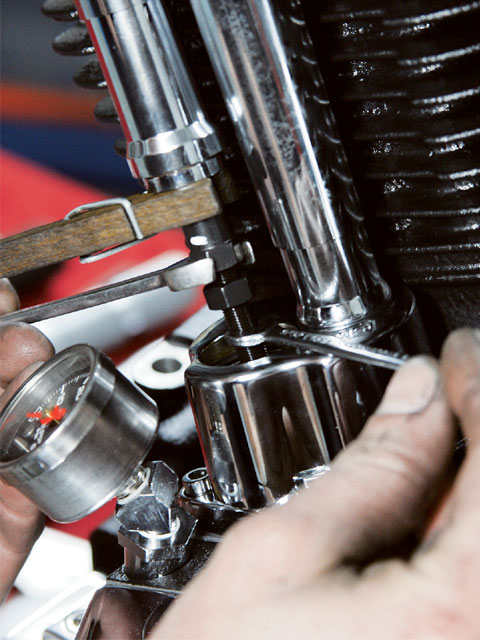

By making the pushrods adjustable, they can be collapsed completely, inserted in place, and then extended to the proper length.

Here’s a good look at the components of the AB Tech pushrod cover. We will be reusing the stock inner pushrod tube (dull-gray piece), spring, and spring washer.

Once assembled, the AB Tech piece will look ike this, with the stock pieces stashed inside.

With the rear cylinder intake pushrod installed, Eric placed the exhaust pushrod in place before adjusting it.

While pushrod adjustment is certainly not rocket science, it is best to consult with the instructions shipped with your pushrods. Better yet, keep an eye out for an upcoming article on that very subject.

Now, that’s one sweet-looking motor. If we did our homework properly, it should run as nice as it looks. Check back next month as we install the charging system.

This month we are ready to pick up right where we left off on our 96-inch Evo build project. When we last worked on the motor, Eric Bennett of Bennett’s Performance had just finished installing a set of JE Pistons, Axtell iron cylinders, and some high-flowing STD heads. For this installment we will be working with TP Engineering Pro-Vent billet rocker boxes, roller rockers, Andrews Products adjustable pushrods, and AB Tech pushrod covers. By the time we finish up today we should have the motor complete with the exception of the Compu-Fire charging system, Mikuni carb, Dyna ignition, and pipes.

We chose to go with the TP Engineering Pro-Vent rocker boxes (part No. 250-20; MSRP: $875) for a few different reasons. First and foremost, Evos are notorious for oil-carryover problems. If you are not familiar with carryover, see HOT BIKE, Vol. 38, No. 5, p. 107 for a detailed explanation. TP’s engineering staff took a long, hard look at carryover and designed the company’s Pro-Vent rocker boxes to, if not eliminate, certainly reduce the effects of carryover. They accomplished this by designing a series of passages and holes in the rocker box that separate the oil from the air, allowing the oil to flow back down to the bottom of the engine. Not only do the Pro-Vent rocker boxes deal with carryover, they are constructed of billet and are very stout. This lends itself to better control of the valvetrain due to decreased flex when compared to stock pieces. The sturdiness of the boxes also helps isolate valvetrain noise to the interior of the boxes, translating into a quieter ride. And if that weren’t enough, we liked the fact that the boxes, along with all of TP’s other components, were made right here in America. TP’s roller rocker arms (part No. 45-0245-23; MSRP: $339.99) were a perfect choice to complete the top end. The pieces from TP’s Pro Series line include a forged 4140-steel design and roller tips designed to reduce friction in an effort to free up every drop of horsepower hidden inside the motor.

Since Harleys ship with non-adjustable pushrods, we tossed the stock ones in favor of a pair of Andrews EV80 EZ-Install pushrods (part No. 292245; MSRP: $120) when we disassembled the motor. In addition to ease of use due to their adjustable design, the Andrews pieces are manufactured from chrome-moly steel for superior strength and rigidity, while still remaining lightweight. Considering how good-looking the motor will be when we are finished with it, we wanted to go with trick pushrod covers that would add to the overall look of the motor. While there are many choices out there, we decided to go with a set from AB Tech (part No. 10-22C; MSRP: $235). Not only do they look great, but they are also sturdily built from solid aluminum rod, then polished and chromed for a brilliant finish.