Building A Stout Twin Cam Crank

1.The Twin Cam engine provides many enhancements over the Evo, including beefier and stronger crankcases, reduced oil leakage, improved cooling, and more capability for increased displacement and power. But to realize its true potential, the Twin Cam requires a few key modifications to eliminate the weak links, starting with the crankshaft. Once the modifications are made, you can build a ground-pounding TC engine without worrying about walking home after whacking the throttle wide open.

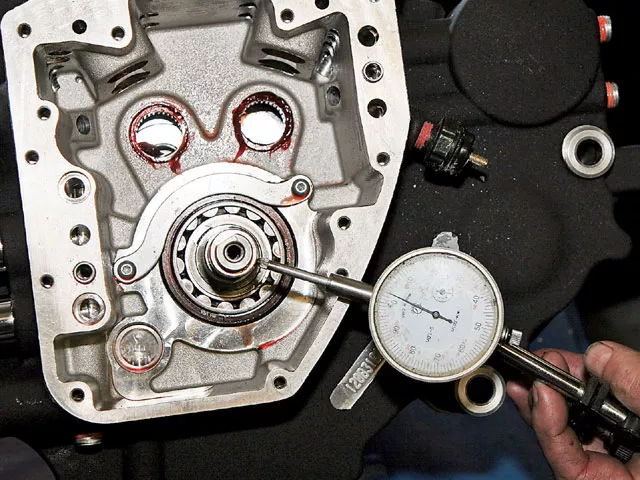

2. Stress from hard deceleration, acceleration, and burnouts can shift a TC’s pressed-together crankshaft and cause .030 inch or more of mainshaft runout. Ideally, shaft runout should be .001 inch or less. A wobbling pinion shaft will damage the oil pump and cam drive mechanism while contaminating the engine’s oil supply, including the oil tank and any oil cooler.

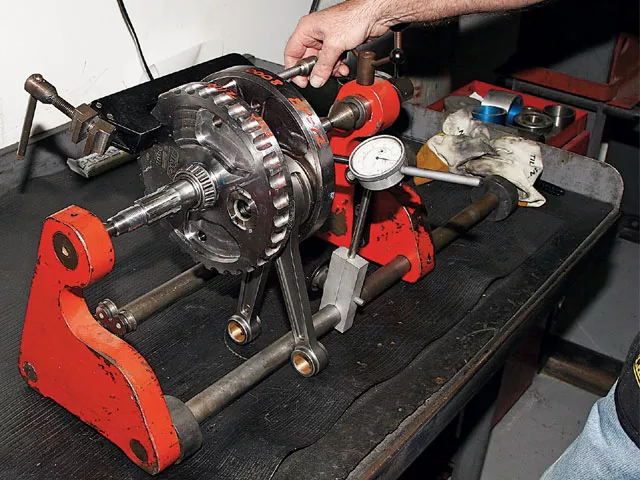

3. Here is Short Block Charlie TIG-welding the crankpin on a new stroker crank. Tack welding the pin at both ends helps eliminate potential crankshaft shifting problems. This crank was checked for true before welding, and then retrued after welding to .001 inch or less of runout. Installing a Timken bearing in the left case (2003-later) also helps minimize crank problems when horsepower reaches roughly 100 and higher.

4. After TIG welding, the TC’s crankshaft assembly is placed on a truing stand for final truing. The flywheels are now trued to .001 inch or less of runout. To simplify final truing adjustments, it is important that the crank is true before welding.

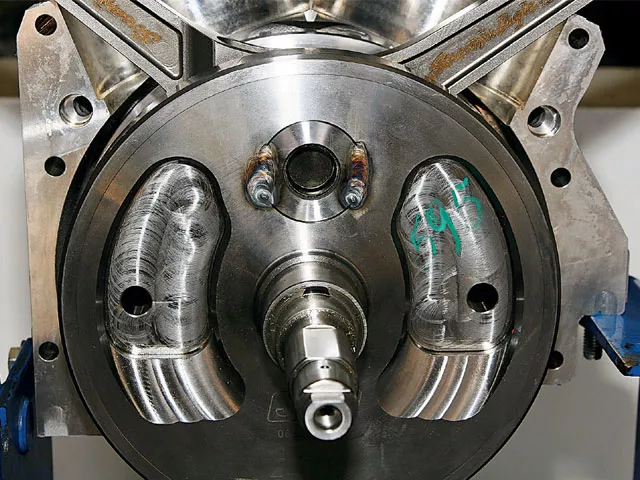

5. Shown is the finished TC crankshaft installed in a left-side engine case of a 120 cubic inch motor. At this point, ThreeBond sealer is applied to the left case before the right-half case is installed over the mainshaft and bolted down. Shown is the right-side pinion shaft that powers the oil pump and camshafts. When the flywheels shift, the pinion shaft wobbles, causing damage to the oil pump, cam support plate, and other cam-related parts.

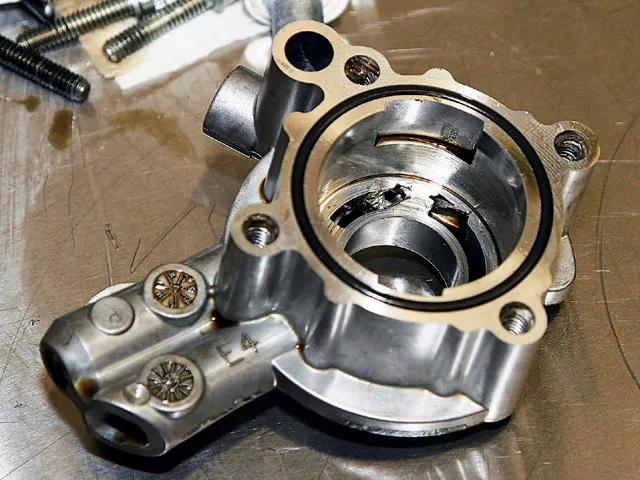

6. Shown is a stock TC gerotor oil pump (early style) with the feed and scavenge gears removed. This pump was damaged by a flywheel assembly that shifted. Notice that the pump housing is fractured and scored at the bottom of the machined gerotor gear cavity because the pump gears wobbled along with the flywheel’s pinion shaft. The gerotor feed and scavenge gears from this pump were also broken.

7. Here is a disassembled view of the late-model TC oil pump. This pump offers 8-percent greater feed capacity and 22-percent greater scavenge capacity over earlier pumps. It is now stock on ’06-up Dynas and all ’07-up models. This pump must be matched with its corresponding cam support plate, which includes hydraulic chain tensioners, roller chains, and cams designed for roller chains. Compare the smooth machined surface of the oil pump’s gear cavity to the damaged pump.

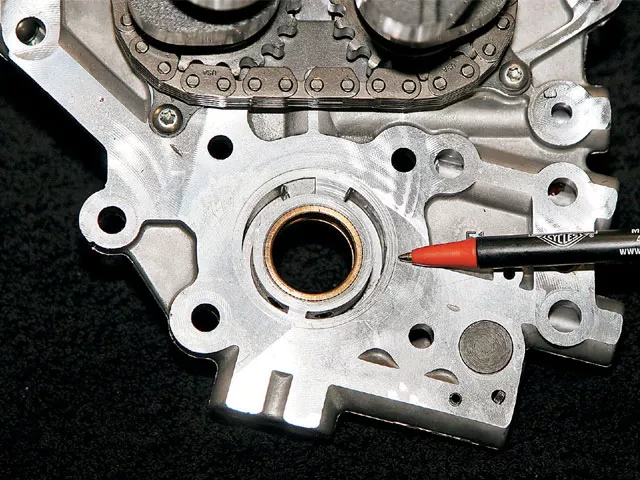

8. Shown is a damaged cam support plate, which was removed from a stock engine with a shifted crankshaft. Take note of the circular wear marks caused by oil pump wobble, which was due to an out-of-true pinion shaft. The gouged area allows oil to leak between the support plate and pump, which quickly gets worse as the engine is run. Eventually, the pump’s scavenge side cannot keep up with the feed side, and excess oil collecting in the engine is tossed out the head breathers.

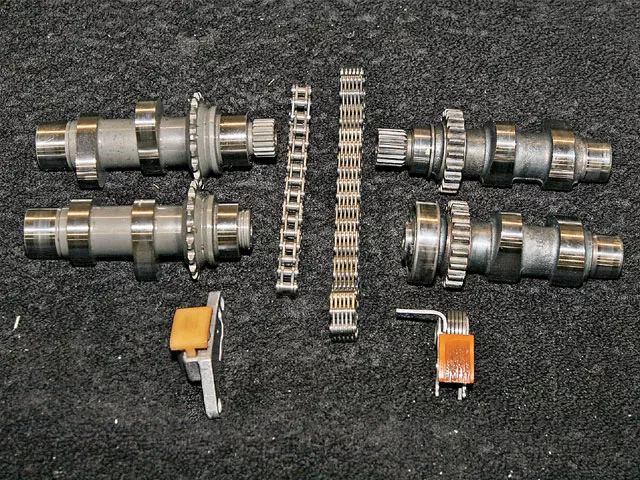

9. Shown is a comparison between the ’07-up roller chain, sprocket and hydraulic tensioner (left) and the ’99-’06 silent chain, cam sprocket, and spring-loaded tensioner (right). Camshafts from the two different designs are not interchangeable because the chain sprockets are different and the ’07-up cams have large journal bearings on their ends. The hydraulic tensioner and roller chain are an upgrade over the silent-chain system, but gear-drive cams are the most bulletproof setup because they eliminate troublesome tensioners and improve cam timing, especially under high valve spring pressures.

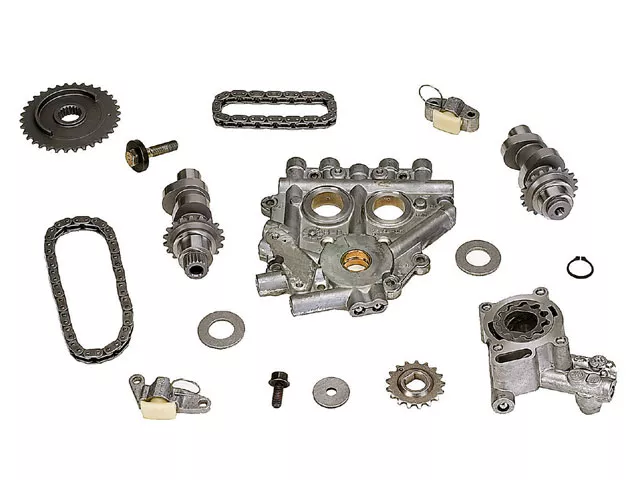

10. This Andrews Products kit upgrades a ’99-’06 Twin Cam engine with spring-loaded cam chain tensioners to an ’07 roller chain drive with hydraulic tensioners. The complete kit is required for the proper matching of parts. The kit includes cams, roller chains, hydraulic tensioners, late-style high-volume oil pump, and supporting parts.

11. Gear-driven cams offered by Andrews Products and S&S; Cycle can eliminate troublesome issues associated with chain-driven cams such as worn tensioner pads and inaccurate cam timing. Gear cams are also helpful when running high valve-spring pressures. Shown are Andrews 64G gear cams pressed into the cam support plate bearings.

Building a stout bottom end is crucial when modifying an engine for increased performance. The Twin Cam engine provides many enhancements over its predecessor, the Evolution, including beefier and stronger crankcases, reduced oil leakage, improved cooling, and more capability for increased displacement and power. Despite these benefits, the TC is not without its warts. Over the years, four critical bottom-end issues have surfaced with the TC engine. Two of those-the lack of a left side Timken bearing on 2003 and later engines, and B-Motor balancer issues-were discussed in the No. 40, Vol. 7 issue of Hot Bike. The other two major issues are crankshaft shifting and the cam drivetrain. In this month’s segment, we’ll address crankshaft shifting, which can cause catastrophic engine damage, while briefly touching upon the cam drivetrain. Short Block Charlie in Tempe, Arizona, invited Hot Bike to follow along as he modified a Twin Cam crankshaft to help prevent shifting.

A seldom talked about Twin Cam engine problem is crankshaft shifting. Unlike the Evolution and Shovelhead cranks, the TC crank is a press-together unit where the crankpin is a “hard” press fit into the two flywheels halves. Under most circumstances, this design works well. However, in some cases, under hard deceleration and acceleration or ground-pounding tire burnouts, the three-piece pressed-together crankshaft can twist out of true, sometimes as much as .030-inch, or even more in the worst situations.

Ideally, the crankshaft should be trued during assembly to within .001-inch. Under high power and torque conditions, a TC’s flywheels can shift on the crankpin, causing the crank assembly to become severely out of true. This results in a severe wobbling of the right-side pinion shaft, which is located in the camshaft’s gearcase. A wobbling pinion shaft often causes catastrophic damage to the engine’s oil pump and cam support plate along with a loss of oil pressure and oil scavenging. Early warning signs include loud noises from the engine’s gearcase area, ticking lifters, and oil dumping out of the cylinder head breathers. Sometimes, the unfortunate bike rider can limp home with the damaged engine. In worst-case situations, the bike needs to be trailered home. Nevertheless, the problem is serious, costly, and a big inconvenience.

The fix for a shifted crankshaft requires complete disassembly of the engine. Generally, the crankshaft, oil pump, camshafts, cam support plate, and cam drive mechanism require replacement. Additionally, debris from the damaged parts ends up circulating throughout the engine, destroying cylinder walls, pistons, rings, lifters, and anything else it contacts. Much of the debris ends up collecting in the oil tank, so the tank requires cleaning. In addition, if you have an oil cooler installed, it too becomes contaminated and should be replaced because coolers are difficult to clean thoroughly. If the engine is under warranty, you may be lucky enough to get it replaced. However, the problem is waiting to zap you again, because a new engine usually includes the same weaknesses as the damaged engine.

Oddly enough, not all Twin Cam cranks shift out of true and result in catastrophic engine damage. The problem is typically hit and miss. Stock cranks (both stroker and non-stroker) are usually the most susceptible to shifting problems, although some aftermarket cranks have been known to twist, too.

Modifying the Crankshaft

In order to properly modify a Twin Cam crank to eliminate twisting, you have to start out with a crank in good condition. It is best to begin with a new crank, but a used one in good condition can also work. Charlie starts by checking the crankshaft assembly for true and makes any necessary adjustments so there is no more than .001 inch runout on the mainshafts. Next, the crankpin is TIG-welded on both ends to the flywheel halves, and then the crank is retrued to within .001 inch or less. The photos show Short Block Charlie TIG-welding the crankpin on a new Twin Cam stroker crank.

If your engine has experienced a twisted crank, most likely the oil pump has been damaged as well as the cam support plate. If those parts need replacing, it is a wise idea to replace them with the 2007-later (2006-later for Dynas) high-volume oil pump and a compatible cam support plate. Since a damaged engine must be disassembled, this is the perfect time to make engine performance upgrades, such as a stroker crank, big-bore cylinders, head modifications, and high-performance cams.

Cam Drivetrain

Regarding the camshafts, you have a choice of either sticking with chain-driven cams or switching to gear-drive versions. Chain-driven cams use two chains and either two spring-loaded adjusters with flat silent chains (’06-earlier) or two hydraulic operated adjusters and roller chains (’06 Dynas and all ’07-up). The hydraulic adjusters are an improvement over the earlier spring-loaded style, but both designs have limitations. The early style spring-loaded tensioners are notorious for experiencing premature wear on the chain pads. Typically, 18,000 to 25,000 miles is the maximum you’ll get on a pair of spring-loaded pads. Also, the debris from the pads can clog internal oil passages. The verdict is still out on pad wear for the hydraulic tensioners. Andrews Products is offering a conversion kit to upgrade ’99 to ’05 silent chain Twin Cams to roller chain drive.

Another concern with chain-driven cams is accurate cam and valve timing. Some high-performance cams require higher valve spring pressures to control valve float and bounce. Since higher valve spring pressure places increased loads on the camshaft, greater demands are placed on the stock chain tensioners. As a result, the tensioners can become overloaded while chain stretch increases, leading to inaccurate cam timing.

Gear-drive cams from Andrews Products and S&S; Cycle eliminate the structural problems associated with stock chain tensioners while producing more accurate cam timing. But keep in mind that gear cams must be checked for proper gear clearance. A fit too tight will produce a whine and can destroy the gears in short order, while a loose fit results in gear clatter. Gear cams are less tolerant of a shifting crankshaft than chain-driven cams because proper gear clearance must be maintained. This is an additional reason to TIG weld the flywheel’s crankpin when installing gear cams. In fact, some aftermarket shops are hesitating to install gear cams unless the crank is properly modified to minimize the potential for shifting.

Summary Thoughts

The Twin Cam is an excellent engine and includes several refinements over the Evolution, including stouter engine components and the potential for increased displacement. However, to realize its true potential, the Twin Cam requires a few key modifications to eliminate the weak links. The modifications start at the crankshaft and extend to the cam drivetrain.