Baker Plus-One Oil Pan – Add An Extra Quart Of Cool

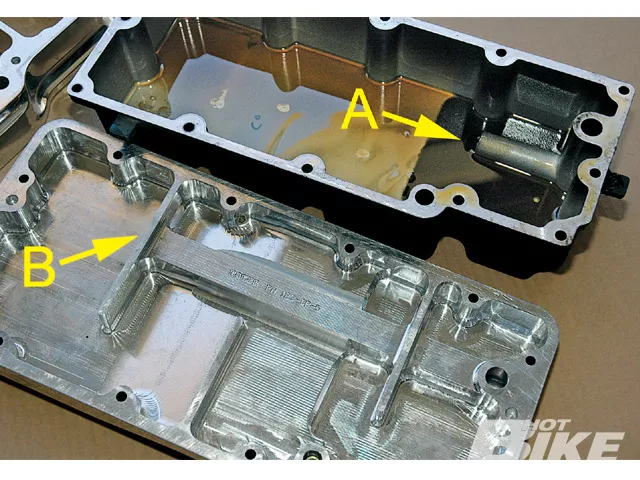

1. Baker’s high quality, two-piece billet aluminum pan comes with everything you need to replace the stock pan. Included are detailed instructions, top and bottom pan sections (shown together here), a stock H-D gasket to mate the top pan to the transmission, a Baker gasket to mate the top and bottom sections, and 12 1/4-20 socket head cap screws (SHCS).

2. To get started we rolled the front wheel onto our Condor Pit-Stop, which is bolted to the garage floor with large eyeblots. We secured the front with tie down straps connected to the eyebolts. Then we lifted the rear end.

3. With the rear wheel resting on a wheel ramp, we removed the lift, disconnected the negative battery cable, removed the saddlebags, and drained the engine and transmission oil.

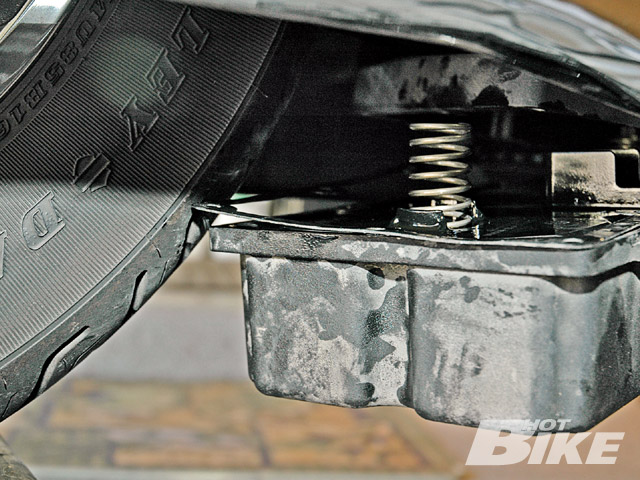

4. Instead of removing the rear wheel, we compressed the rear shocks and held the rear end down with a tie down strap. This pushed the frame down and away from the rear tire.

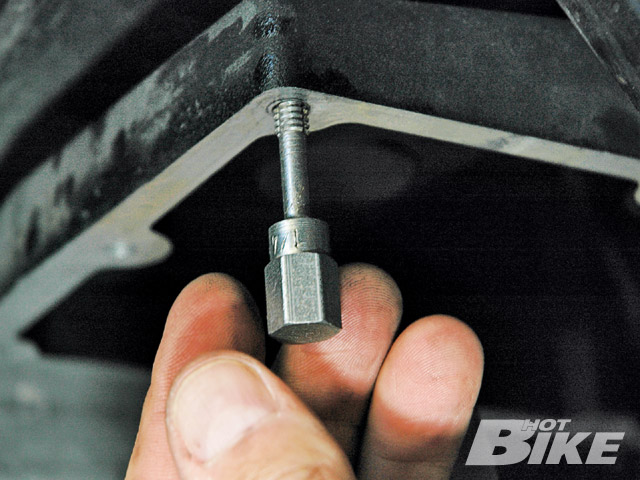

5. With a 3/16-inch hex socket we removed the screws from the stock pan. A little maneuvering of the stock pan was required to slide it out and past the rear tire. The photo shows the clearance. We also used a long screwdriver to push down on the pan’s inner baffle springs.

6. Here we used a 1/4-20 re-threading tap to chase the holes in the aluminum transmission case. Re-threading taps and dies remove nicks and burrs from the threads and are less likely to cross thread a hole than hardened cutting taps and dies. A little solvent and compressed air finished the job.

7. Before installation, we separated the top and bottom parts of the new oil pan retaining the gasket and bolts for later. Then we cleaned any debris with a non-residue solvent (like brake cleaner) and blew out all holes.

8. Here’s a comparison of the stock oil pan (top) and bottom half of the Baker Plus-One. Note that in the stock pan, the oil return port (A) is close to the front where the oil pick-up port is located. While in the Plus-One, the oil return port (B) is near the rear of the pan which forces hot returning oil to travel the length of pan before pick up.

9. A thin coat of Hylomar gasket sealer was spread on the Plus-One top half surface and on the matching surface of the transmission case. When allowed to dry until tacky, it will help hold the gasket in place and seal it.

10. We installed the top half of the Plus-One using the 12 1/4-20 socket head cap screws using blue threadlocker, making sure the gasket was aligned. Then we snugged the screws evenly.

11. All bolts were torqued to 110 in-lb following the sequence in the instructions.

12. Here we test fit the bottom half of the Plus-One, without a gasket, under the top pan aligning the top dowels with the bottom holes. There was plenty of room to slip the thin bottom pan into place.

13. The test fit revealed a problem. One of the bottom pan fasteners was inaccessible above the crossmember. Since the factory already provided access holes for two stock screws, we figured one more hole wouldn’t hurt. So we carefully marked and center punched the location directly under the problem screw and then drilled a 1/4-inch hole to slip our hex socket through.

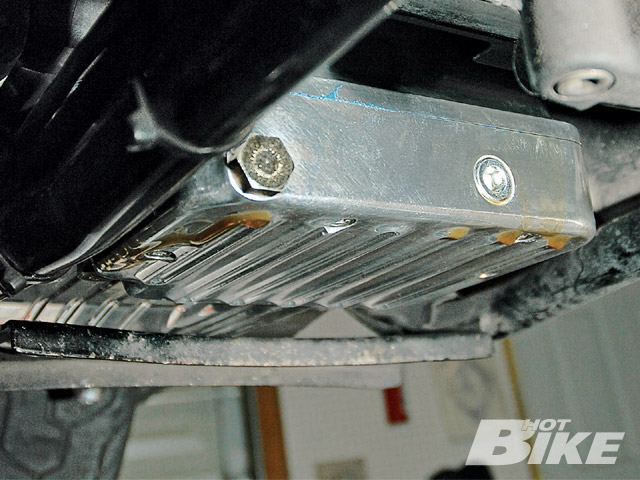

14. With another application of Hylomar and placement of the gasket, we slipped the bottom pan in and pushed it up onto the top pan. All 12 bolts were inserted, and torqued to 110 in-lb.

15. We filled the transmission and oil pan with fresh H-D Syn3 then checked the fluid levels. Be sure to add an extra quart to the oil pan, hence the name Plus-One Oil Pan.

16. Oops. Oil immediately began to leak down the front and side of the pan. The leaks appeared to come from the seal between the top and bottom pan sections and not from the top pan and transmission case. We re-drained all the fresh oil into a clean pan and saved it. Then we pulled the bottom pan for inspection.

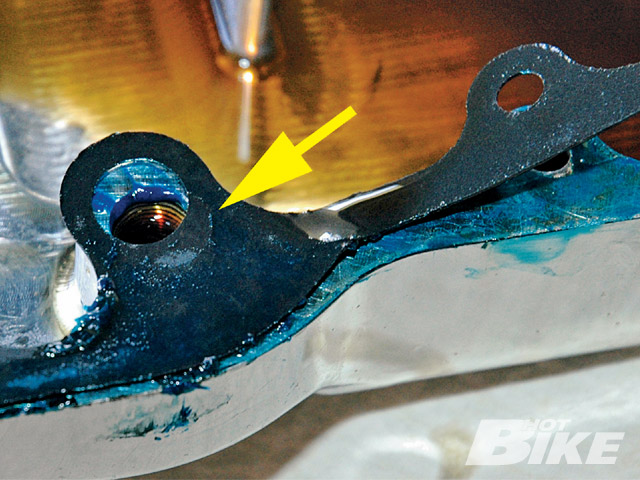

17. Oops again, our bad. We failed to heed the warning in the instructions to take critical care with this gasket. We only used normal care and allowed the gasket to slip about 1/4-inch, enough to block half the transmission drain hole (arrow) and kink the gasket. No wonder it leaked like a cheap rain suit. Fortunately, Chris at Baker Drivetrain responded to our urgent call and FedEx’d a replacement gasket.

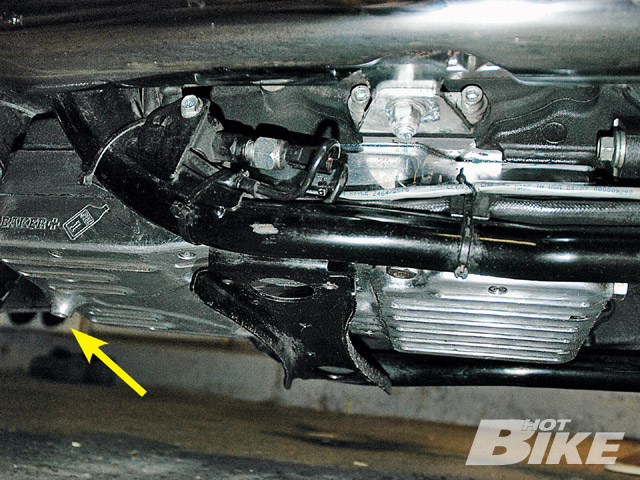

18. Humbled now, with the new gasket and using critical care, no leaks were present, even after we took a short test ride. Now that’s cool, really. Here’s the boss (arrow) for the TXR which we’ll cover next month.

Baker Drivetrain understands that nobody changes a motorcycle oil pan for purely aesthetic reasons. That’s why they designed their Baker Plus-One Oil Pan (+1P, MSRP: starting at $399) to not only look great but also to add some key functional features like improved oil cooling and a built in stabilizer boss. The Plus-One fits 1993-2008 Harley-Davidson FL motorcycles.

The reduced engine oil temperature (Baker claims 10 degrees on an 80 degree day) is achieved by enlarging the pan capacity to add an extra quart of oil, by moving the hot oil return port to the rear of the pan (the stock pan has the oil return and oil pick up both near the front), by using multiple internal aluminum baffles to eliminate the stock plastic baffle, and by adding cooling fins on the bottom of the pan.

Plus, to keep from hiding their oil pan under a wide, stabilizer trans plate, Baker added a structurally located, integral boss for the Alloy Art TXR stabilizer. That makes adding the TXR a snap, which we’ll cover in a later issue.

Oh, and that aesthetic thing, the Plus-One comes in two attractive styles; either a one-piece cast aluminum pan in black or natural finishes that will match your stock motor or a two-piece billet aluminum pan in chrome or polished finishes that will add some light where the sun don’t shine. We were happy to install the two-piece polished pan on our 2007 Road King Custom.

The Baker oil pan installation instructions, as well as the factory service manual, call for removing the rear wheel and the swingarm pivot shaft, then raising the transmission about an inch above the frame crossmember for clearance of the oil pan. However, we don’t like to remove any unnecessary stuff, so we tried a different technique to save time. We raised the rear of the bike about a foot and rested the rear wheel on a wheel ramp. Then we compressed the rear shocks and held them with a tie-down strap. Effectively, this is pushing down on the rear frame struts, which then pushed the lower frame down and away from the rear tire and created a sufficient gap to slide the stock oil pan out and the new Baker pan in. This also gave us room to work under the bike. It was a close fit but certainly a lot less work than removing the rear wheel and pivot shaft. Of course, this trick may not work with your model.

To determine the temperature reducing performance of the Plus-One, we used two different temperature measurement techniques to compare before and after values. With the stock pan we rode the bike to get the engine up to normal operating temperature. Then we noted the Engine Temperature (ET) in the log from our Daytona Twin Tec TCFI engine module and we measured the external engine temperatures in two places with our infrared thermometer. After installing the Baker oil pan, we again rode the bike and re-measured. All temperatures are in degrees Fahrenheit. The results are shown in the following table.

| BEFORE | AFTER | VAR | |

| Ambient Temperature | 81 | 82 | 1 |

| Daytona {{{TT}}} TCFI Log | 261 | 253 | -8 |

| Infared at Front of oil pan | 192 | 188 | -4 |

| Infared at Crank case by oil pump | 215 | 209 | -6 |

As you can see, the Plus-One oil pan brought the temperature down a few degrees, but on our runs, not the 10 degrees claimed by Baker. However, we should note that it’s difficult to compare oil temperatures. The infrared thermometer doesn’t read shiny surfaces very well so we got some variations on the polished pan. With the log data, we tried to pick comparable spots in each run but it’s not precise. We were encouraged though that the data showed lower temperatures. We’ll take those anytime.