95-inch Twin-Cam Upgrade

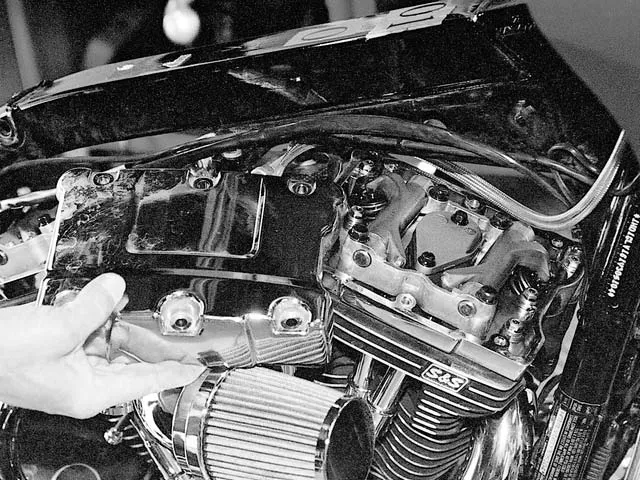

Here is a good shot inside of the top of the rocker box. Notice the two-chamber design of the air/oil separator on the left and the rocker clearances machined into the back and front of the box. As an added bonus, TP Engineering provides extra gasket material for the air/oil separating chamber. Next time you take the top off the boxes in the future, you can replace the gasket.

The lower rocker box is just as gorgeous as its counterpart on top. Check out the precision-machined rocker arm shaft bores and the air/oil separation chamber on the right.

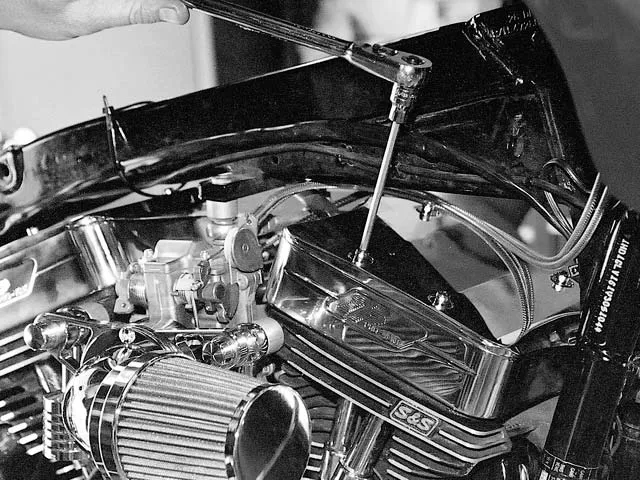

To get the stock rocker boxes off, we had to remove the seat and gas tank.

We then unbolted each of the stock upper rocker boxes.

This photo illustrates where the rocker arms rockers were coming in contact with one of the support gussets of the rocker boxes — one of the reasons our valvetrain was making so much noise.

TP Engineering rocker boxes (on the left) are machined for more clearance in contrast to the stock boxes.

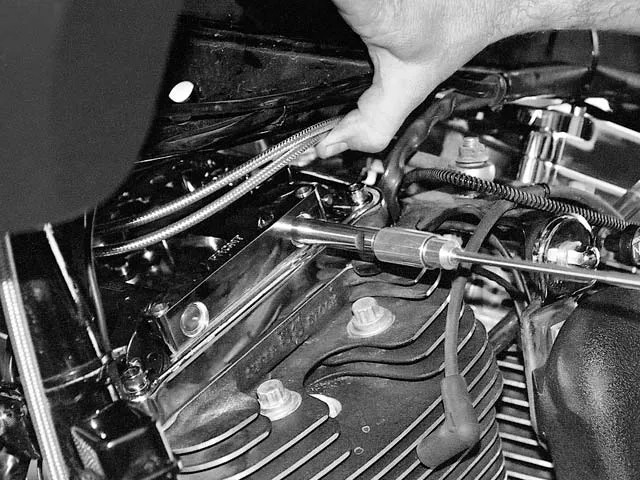

With a box-end ratchet, we removed the stock rocker assembly.

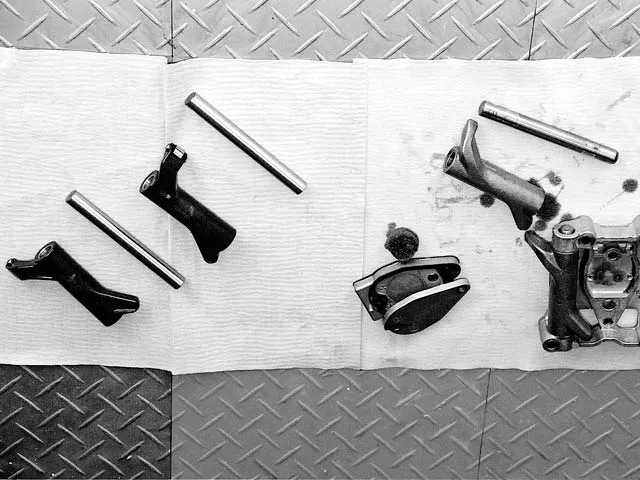

On the left is a view of the stock rocker and breather assembly versus our new, simpler JIMS 1.625 ratio roller rocker arms and rocker shafts.

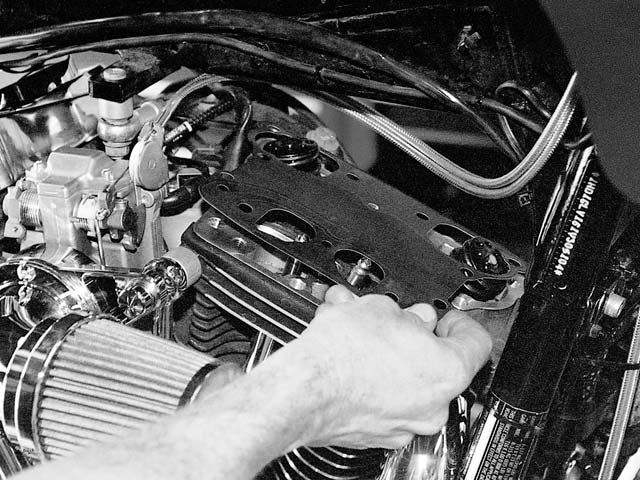

We installed a new gasket before the lower rocker box…

…and slid the new TP unit in place.

The TP shafts are marked to indicate where the relief is for the lower box mounting bolt. We used use a magnet to pull this shaft out and realign it.

Each JIMS roller rocker arm is specifically labeled for proper placement in the rocker boxes. Photo 12B is a close up view of the roller tip and inner brass bushing that carries the rocker shaft.

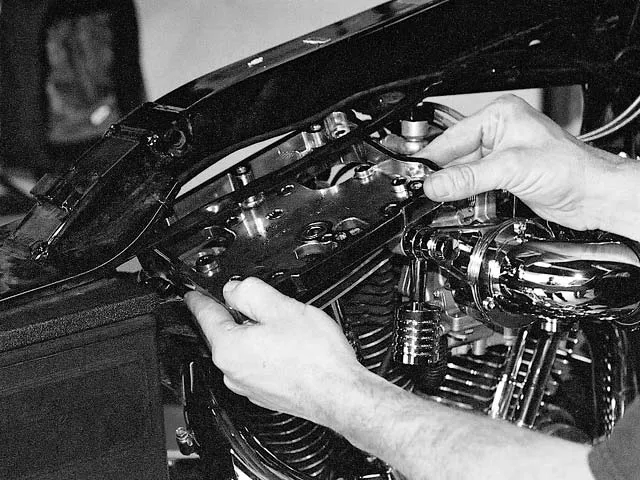

We tightened up the lower boxes and rockers…

…with a little medium-strength thread locker…

…and the appropriate bolt and washer combination. We then bolted down the top of the rocker box covers.

We already had adjustable pushrods installed on our Twin Cam, but to be safe, we did the adjustment again. Adjustable pushrods are available in a variety of thread pitches; adjust your pushrods to their particular specifications.

The finished product! Not only did we hear less valvetrain noise, we were positive that the boxes were not interfering with the rockers. The TP Engineering rocker boxes really give the engine a beefier appearance, and the chrome adds to the bike’s good looks.

Hot rodded Twin Cams are notorious for excessive valvetrain noise. Our 95-inch Twin Cam was no exception, emitting all kinds of valve noise that was accentuated by rocker-to-rocker box contact. We decided to see what we could do about the problem and contacted TP Engineering to try a set of its brand-new Pro-Vent rocker boxes and a set of JIMS roller rockers.

When a package arrived at our office with TP Engineering labels, we opened it and were very impressed with the quality of the chrome and the oversized look of the new Pro-Vents. The beautiful TP Engineering rocker boxes are precision machined from super-strong billet aluminum with added wall thickness for greater strength and noise reduction. The boxes’ dual-chamber design provides better air/oil separation, and, more importantly, has plenty of rocker clearance for higher lift cams.

The JIMS stock ratio roller rockers were delivered shortly after the rocker boxes and turned out to be just as cool — cast from 4340 chrome-moly, then heat-treated for maximum strength. In addition, the rockers will help reduce some of the valvetrain noise with their low-friction rollers and high-quality brass bushings.