From 88ci To 106ci With S&S Cycle

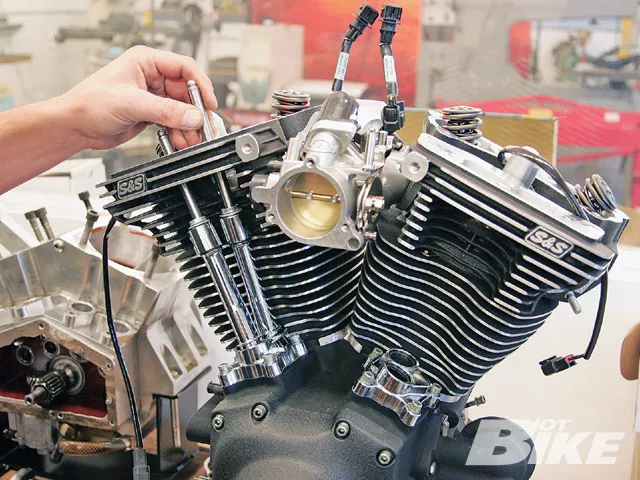

1. Here is the motor where we last left off. The lower end was together, and the pistons were installed. The cylinders were slid down over the piston and rings, then the motor was rotated to position the piston to top dead center (TDC) to check for any clearance issues. We were getting ready to install the heads and rockers, then build the S&S; throttle body and install the S&S; air cleaner kit.

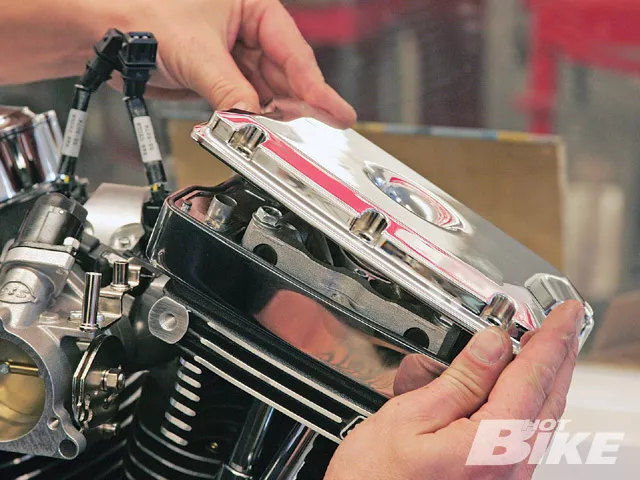

2. The S&S; 106ci kit includes all the gaskets needed for the motor, so Eric placed a new set of head gaskets onto the cylinders, then placed the S&S; high-flow Super Stock cylinder heads onto the motor. The heads feature S&S;’s new Sidewinder single-coil valvesprings. These help quiet down the valvetrain by reducing the spring noise in the rocker boxes.

3. Before installing the heads, a dab of anti-seize was placed on the head bolt threads, washers, and cylinder studs to eliminate false readings on the torque wrench caused by binding, and to allow proper seating of the gaskets.

4. Next, Eric torqued the head bolts according to S&S; specs.

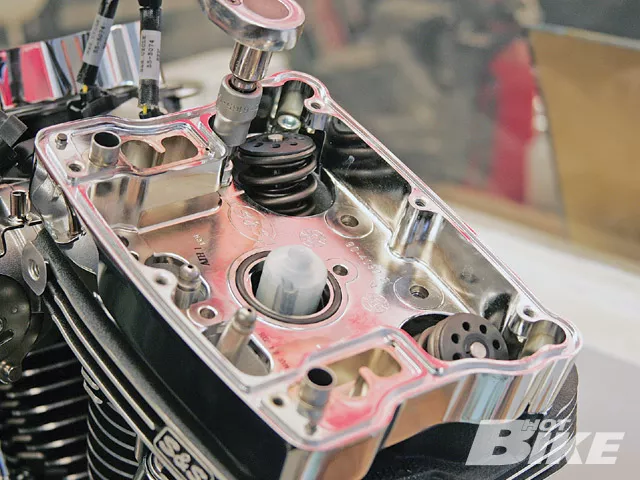

5. A set of S&S; electronic compression releases were installed in the heads to lighten the load on the starter. They were wired into the starting circuit so that once the key is on, power is sent to open the valves. Once the starter button is depressed and the motor is started, the valves close, bringing the motor back to operating compression.

6. Due to the wires on top of the compression releases, Eric used a two-piece S&S; compression-release socket to install the releases into the heads.

7. First the compression release was threaded into the porthole in the top of the head by hand, then the wire was fished through the top of the socket (arrow).

8. Eric tightened and torqued the compression releases to S&S; specs.

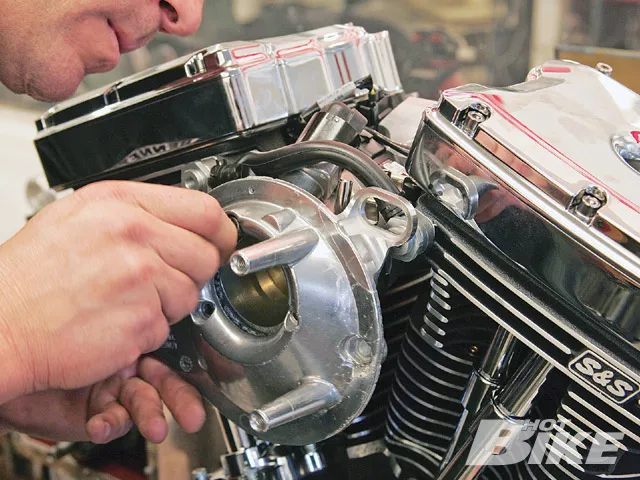

9. The next thing Eric worked on was the EFI system. The S&S; single bore throttle body kit includes a throttle body assembly, fuel injectors, fuel rail, harness adaptors, and all the hardware, gaskets, S&S; intake manifold, and hoses needed for installation.

10. The single bore throttle body is essentially the same size as an S&S; Super G carburetor body, with a 52mm bore.

11. To get started the first thing Eric did was bolt the throttle body and the intake manifold together. There is a set of O-rings that need to get placed between the body and manifold.

12. Next, the MAP sensor was bolted to the manifold along with the throttle cable mount.

13. Then the idle air control motor with S&S; O-ring and seal was installed. Note that there are different motors for specific applications so if you order a kit make sure to check the part number for your specific year and model bike.

14. Erick installed the throttle position sensor to the right side of the theottle body.

15. Here is a look at the fuel injector installed into the fuel rail before it was installed into the manifold. If you look you can see that the O-rings and seals were treated to a bit of lube to keep from damaging the O-rings as they were installed to ensure no leaks.

16. Once the fuel rail was installed, Eric installed the fuel tube and clip. Then the wire harnesses for the fuel injectors were plugged into the injectors.

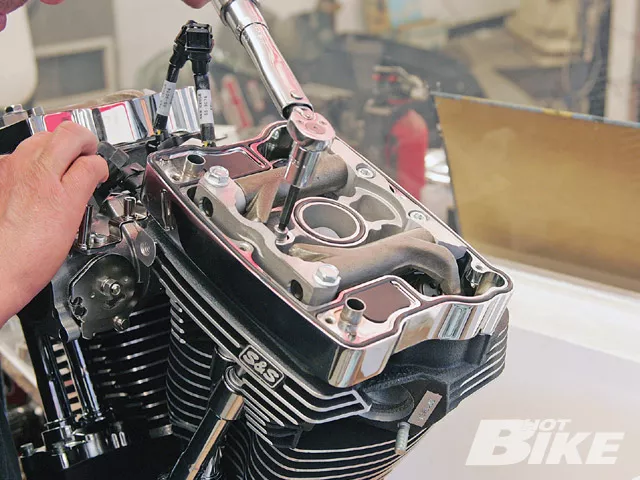

17. With the rocker boxes off, Eric took advantage of the room to install the EFI throttle body.

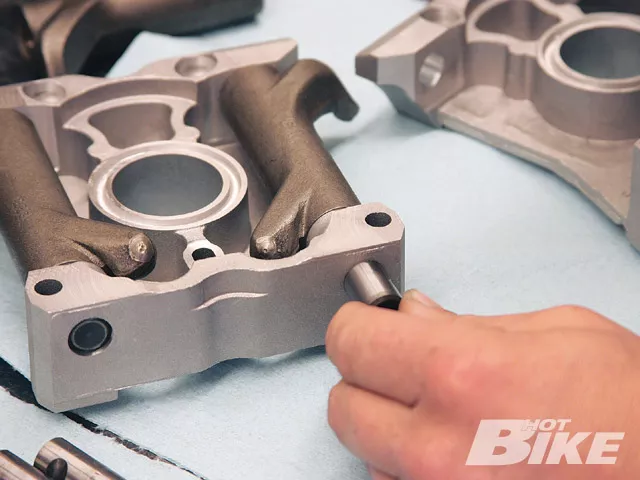

18. Here are the S&S; adjustable chrome moly pushrods, chrome pushrod tubes, and the O-ring sets that are part of this kit.

19. Eric assembled the pushrod tubes, put them in place, and installed the pushrods.

20. The next thing was to install the rockers and the rocker boxes. S&S; rocker covers include Viton O-ring style cover seals for leak-free operation, the two-piece design makes for a simple installation. Starting with the lower, after the gasket was placed onto the head Eric bolted the S&S; lower rocker box down and torqued it to factory spec.

21. Eric installed the rocker assembly, and with the rocker arms in place he slid the rocker arm shafts through the support arm.

22. Once the rocker assembly was together, Eric installed the rockers in place and lined up the pushrods, then bolted and torqued the assembly to the heads.

23. After the lifters had time to bleed down, Eric adjusted the pushrods…

24. …and the top rocker box covers were bolted down to spec.

25. Then the backing plate for the S&S; teardrop air cleaner assembly was installed.

26. Lastly the S&S; filter and cover was bolted to the motor.

27. There you have it, the motor is now 106 ci of mean S&S; parts! Next issue we’ll bolt the motor back into the bike, install the S&S; fuel management system and the Thunderheader exhaust, then enjoy about 1,000 miles before we Dyno run the bike…so check back next month for the wrap up.

Here we are with part II of the S&S; 106ci Hot Setup kit on our ’02 Road King. To get you up to speed just in case someone stole your copy of last month’s (Vol 41, No 4) issue, we spent some time with Eric and Bob Bennett at Bennett’s Performance in Signal Hill, California. We left off with Eric and Bob putting the lower end together, fitting the pistons to the cylinders, installing the cams, lifters, and oil pump, and everything in between.

In this issue we’re wrapping up the top end and building the new S&S; Single Bore VFI assembly. As soon as we get the motor back in the bike, we can program the new S&S; EFI system. For better tuning capabilities we are updating the bike from an open-loop system to a closed-loop system, so we will need to weld in exhaust bosses for the oxygen sensor. We’ll cover more on this next issue. Then we will put as many miles on the bike as we can, and get the final numbers.